- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

- PVC coated fabrics

- TPO coated fabric

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

Anti scratch Flooring Sheet Decorative PVC Printing Film

widely used for the promotion of flat ground in various shopping malls, subways, studio event halls, etc.

- Banner stand, Display stand use, Advertising board. - Supermarket, Store, shopping mall, poster - Photographic Studio, light box, subway station and so on - Indoor usage |

|

|

Anti-scratch Flooring Sheet Decorative PVC Printed Film DERFLEX is professional floor pvc film manufacturer for keeping social distancee, with experience over 20 years.

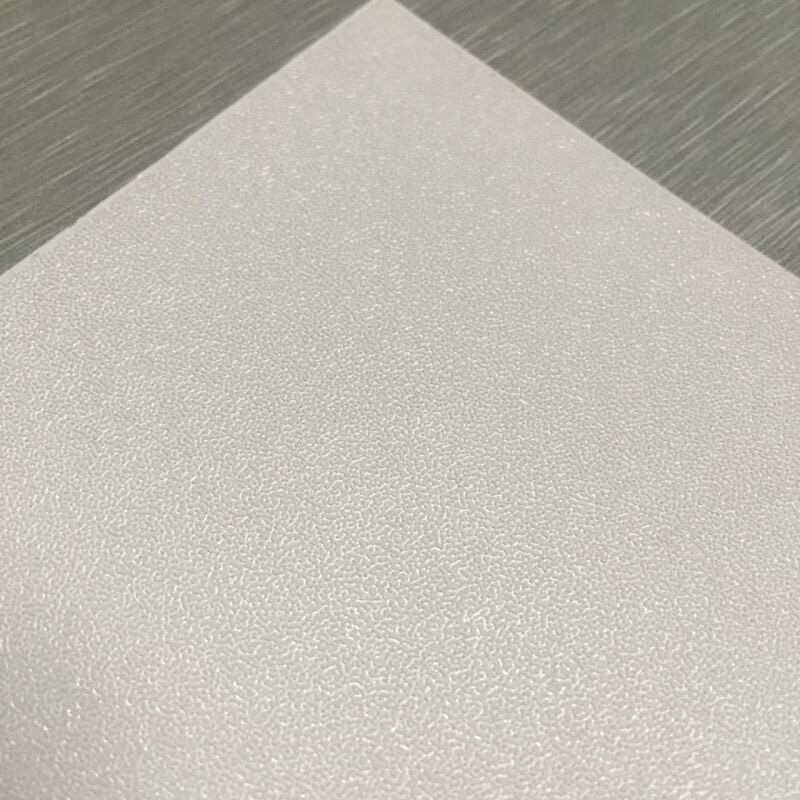

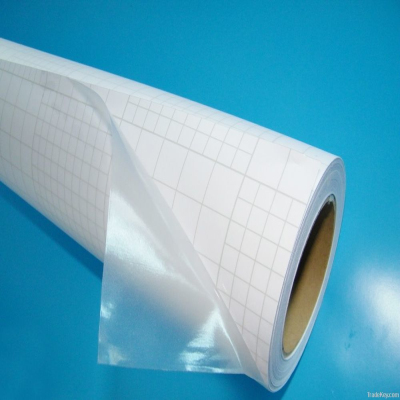

Product description The concave-convex floor film, also known as non-slip floor film, uses a hard thick PVC mask, which is a matte transparent film. Unique concave-convex pattern, which plays a role of anti-skid and anti-friction. It is used in conjunction with the removable adhesive product screen and is widely used in the production of posters on the ground.

1) vinyl floor stickers Product information:

Product Usage Matte floor membrane is widely used for the promotion of flat ground in various shopping malls, subways, studio event halls, etc. (1) Good homogeneity: Synthetic polymer waterproof membranes are all produced by factory mechanization, and the quality of products can be better controlled during the production process. Widely used as Social distance floor sign sticker roll for advertising printing

Manufacturing Technique

Floor sticker sign rolls Processing Methods * High-Frequency Welding, * Sewing, * Printing, * Adding Adhesive, * Hot Stamping, * Laminating, etc.  Production area 60,000 square meter, registered with 2,5 million US dollars. 5 calendars, 3 coating machines and

5 lamination machines, 25 senior engineers and 400 workers make our factory more competitive among the PVC sheet roll supplies.

For more information

Would you please contact: Whatsup 0086 17316447897 |