- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

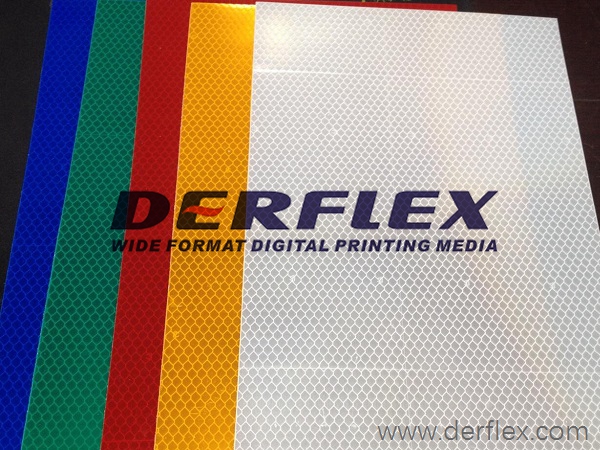

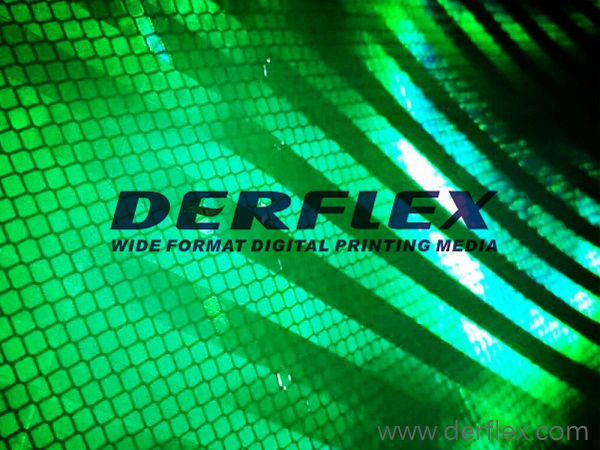

Diamond grade reflective sheeting

The performance of diamond grade reflective films belongs to the first and second grade reflective films of the JT-T279-1995 standard issued by the Ministry of Communications of the People's Republic of China. Its reflective principle is different from that of glass beads used in engineering grade and high-strength grade reflective films. Instead, it uses the latest technology in crystallite cube reflection.

|

|

|

The performance of diamond grade reflective films belongs to the first and second grade reflective films of the JT-T279-1995 standard issued by the Ministry of Communications of the People's Republic of China. Its reflective principle is different from that of glass beads used in engineering grade and high-strength grade reflective films. Instead, it uses the latest technology in crystallite cube reflection. Each crystallite cube of the diamond grade retroreflective vinyl film is arranged to have more than 930 microcubes in one square centimeter of material. The lower layer of the microcrystalline cube corner body is sealed to form an air layer, so that the incident light forms internal total reflection, so that the most superior light reflection effect can be achieved without using a metal reflective layer. Compared with the traditional engineering grade and high-strength grade reflective film, the reflective grade of diamond-grade reflective film made of wear-resisting high-hardness polycarbonate material and microcrystal cube technology not only doubles, but also has wide-angle performance. improve. The brightness of the diamond grade reflective film is more than six times that of the engineering grade and three times that of the high-grade. Applicable to traffic signs on high-grade highways and urban roads. Under normal use conditions, the brightness retention after 10 years is at least 50% of the initial brightness value. Using the same type of ink, various patterns can be made using screen printing technology. Uses: Guide signs; prohibition signs, warning signs and indication signs, and signs used in ordinary advertising. Lifetime: Generally, 10 years, under normal use, this series of reflective film has a brightness retention value of at least 50% of the initial brightness value after 10 years. Applicable base plate: Aluminum plate, steel plate. Operating temperature: General requirements at 18 °C ~ 28 °C. DERFLEX is professional retroreflective manufacturer in China, if you have more interest in our products, please contact us freely. |