First, the performance characteristics of acrylic sheet and application areas

Excellent optical properties (high transmittance of 92%); high surface gloss, bright color, full, smooth, good hardness; chemical resistance; stable performance is not easy to deformation; complete product range, colorful and varied Surface effect; physical stability (easy molding, plasticity); weather resistance, anti-ultraviolet ability, not easy to oxidation (high and low temperature deformation resistance of high temperature 70 degrees, 50 degrees low temperature); green, waste materials can be recycled Use; excellent surface hardness and scratch resistance; easy to clean, maintenance; outdoor 5-8 years will not fade, loss of light, not open. The impact resistance is outstanding and is suitable for installation in a relatively safe installation area. Itself light weight, the building objects and support to bear the load requirements are low.

Application areas: A: Aerospace industry B: Expressway C: Civil industry D: Advertising industry F: Bathroom industry G: Other forms of advertising

Second, the acrylic plate production process and classification

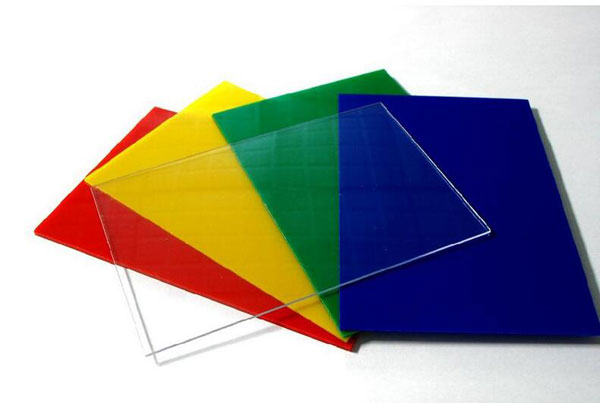

1, the acrylic plate according to the production process sub-cast plate and squeeze plate, according to the light can be divided into transparent plate, translucent board (including the stained board transparent board); performance by sub-impact plate, anti-UV board, color plate (Including black and white and color board), ordinary board and special board such as high impact plate, flame retardant board, matte board, metal effect board, high wear plate, light guide plate

A: cast plate: high molecular weight, with excellent stiffness, strength and excellent resistance to chemical properties. And thus more suitable for processing large-size identification plaque, relative to the softening process in a little longer. This plate is characterized by small batch processing, in the color system and surface texture effects have unparalleled flexibility, and product specifications complete, practical for a variety of special purposes.

B: Extrusion plate: Compared with the cast plate, the extruder has a low molecular weight, a slightly lower mechanical property and a higher flexibility. However, this feature is conducive to bending and thermoforming processing, softening time is shorter. In dealing with large size of the plate, is conducive to a variety of rapid vacuum plastic molding. At the same time, the thickness tolerance of the extruded plate is smaller than that of the casting plate. As the squeeze plate is a large number of automated production, color and specifications inconvenience conditioning, so the product specifications diversity subject to certain restrictions.

2, there is a kind of acrylic called back to the recycled plate is the use of recycled acrylic scrap, after thermal degradation to be recycled MMA (methyl methacrylate) monomer, and then by chemical polymerization reaction. After a rigorous process, you can regain the pure MMA monomer, with the new synthetic monomer, there is no difference in quality. But the production of degraded monomer, the purity is not high, sheet metal forming, from the quality, poor performance.

Summary: Extrusion plate using pellet raw materials, after high temperature dissolved after extrusion molding, and casting plate is MMA monomer (liquid) direct casting molding, although the extrusion plate shape is relatively smooth and smooth, but because of its particle in the raw material molding To complete the aggregation. In the processing of sheet metal when its structure, performance is weak, not suitable for outdoor identification products as a material, only suitable for crystal word or product stent and other indoor products. In addition, most of the extruded plate does not have anti-ultraviolet function, its outdoor life and casting plate is quite different, the color will fade and easily brittle, until the rupture. Casting plate is in the process of processing the plate to complete the structure of polymerization, during which the addition of UV absorbers, with high strength and UV function, outdoor life of up to 5 years or even 10 years, the use of color has been bright as new.

Third, pure new material acrylic plate and the regeneration of the simple distinction and identification method

Distinguish the method:

1, pure new transparent acrylic sheet: A: light transmittance greater than 92%, transparent and colorless cross-section B: anti-ultraviolet performance, outdoor 5-8 years do not fade, loss of light, yellowing, cracking C: high surface hardness , With aluminum and brass equivalent D: anti-cracking and anti-chemical performance E: high-quality protective film, providing adequate protection

2, recycled material recycled board transparent acrylic board: A: light transmission rate of less than 86%, cross section at the yellow B: anti-ultraviolet performance is very poor, up to six months will be yellowing, the sun is prone to cracks C: Easy to scratch D: easy to crack E: protective film of poor quality, easy aging deterioration.

Identification method: 1, back to the new material recycling board: A: regeneration plate appearance yellowing. B: the surface is easy to scratch, cutting is to stimulate the smell. C: Thermoformed heating, prone to bubble deformation. D: sensitive to paint, ink, prone to crazing or crack. E: When burning, blistering black smoke and irritating smell.

3, pure new material acrylic board: A: the appearance of pure color reproduction plate, especially from the cross-section is obvious. B: excellent surface hardness and scratch resistance, cutting is no irritating smell. C: Thermoforming heating, it is not easy to produce bubbles and deformation. D: the paint, ink adaptability and stability. E: When burning, no blistering No black smoke No irritation.