basic introduction

Product Introduction

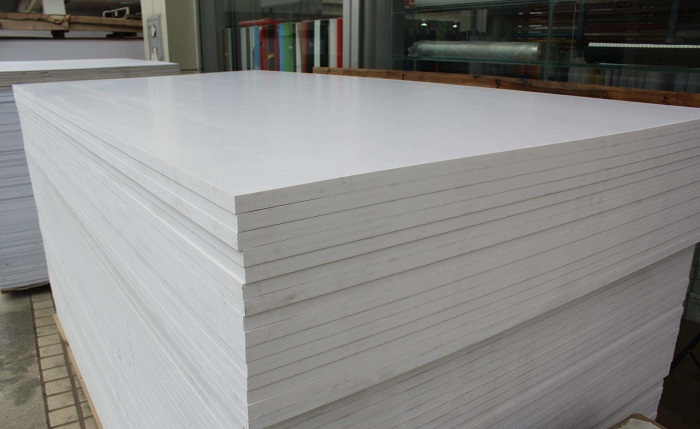

PVC free foam board, also known as snow Fu board and Andy board, the chemical composition of PVC

Product specifications

1220 * 2440mm, 1560 * 3050mm, 2050 * 3050mm

Product thickness

1-33mm

Product density

0.35-0.8

Features

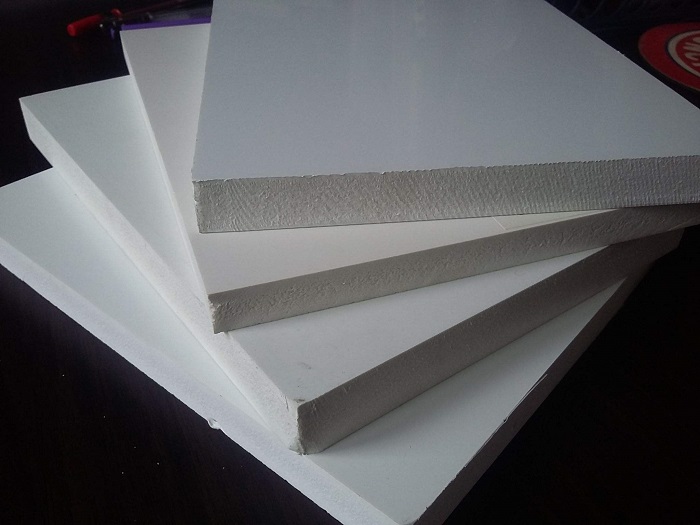

1. Waterproof, flame retardant, Naisuan Jian, Fang Zhu, light weight, insulation, noise, shock absorption characteristics

2. And wood processing the same, and processing performance is far better than wood

3. It is an ideal substitute for wood, aluminum and composite sheet

4. Leather surface is very smooth, high hardness, not easy to scratches, commonly used in the production of cabinets, furniture, etc.

Product use edits

Widely used in passenger cars, train car roof, box core layer, interior decoration board, building exterior panels, interior decoration board, office, residential, public places building compartment, commercial decoration frame, clean room board , Hot plate, special cold storage project, environmental protection board mold, sports equipment, aquaculture materials, the use of the board, the board, the board, the board, the board and so on. , Beach moisture-proof facilities, water-resistant materials, art materials and a variety of lightweight partitions instead of glass ceiling.

PVC free foam board surface hardness in general, widely used in advertising panels, mounting board, silk screen, sculpture, etc.

Product Features

● PVC free foam sheet, with noise, sound absorption, heat insulation, insulation and other properties.

● PVC free foam board board with flame retardant, self-extinguishing fire, you can safely use.

● PVC free foam board The series of products are moisture, mildew, non-absorbent performance, and shock effect is good.

● PVC free foam board The series of products made by weathering formula, the color can be long and constant, not aging.

● PVC free foam board texture light, storage and transportation, construction convenience.

● PVC free foam board can be used for general wood processing tools.

● PVC free foam board can be the same as wood drilling, sawing, nailing, planing, sticky and other processing.

● PVC free foam board can be applied to thermoforming, heating bending and folding processing.

● PVC free foam board can be welded according to the general welding procedures, but also with other PVC material bonding.

● PVC free foam board its surface is rough, also printed.

PVC

A terrible fires

For many years, people think that PVC is a harmonious nature of an artificial note, that it destroys the environment is not conducive to ecological development. In 1996, a sensation was made at Düsseldorf Airport, and some 17 people were killed by fire. Some misleading public opinion led people to treat the PVC as the culprit of the fire, which undoubtedly increased the misunderstanding of PVC The

Second, the beautiful appearance

The surface and shape of the goods will leave a first impression. Advertising psychologists believe that this first impression for the sale of the product plays a decisive role. From this layer of meaning, PVC film market prospects are very good. In fact, with the development of the times, PVC is also its good performance, simple technology and many other advantages gradually won the people's favor, has been more and more people to accept and recognition in Europe and the United States PVC is The darling of the construction industry, PVC in people's daily life can be seen everywhere. PVC can not only show the color of nature, but also can show people in the fantasy of color. In Germany, 40% of the furniture is made of PVC for the surface material, see those natural color, colorful, rich and varied, beautiful patterns, elegant and high-grade style desk, bookshelves, sofa, kitchen cabinets, who do not Will they and the streets of those devastated "white garbage" together, but will not think it is PVC plastic film to give them so beautiful coat.

Third, the perfect structure

So what is PVC in the end? PVC full name is Polyvinylchlorid, the main component of polyvinyl chloride, and other ingredients to enhance its heat resistance, toughness, ductility and so on. The top layer of this surface film is a paint, the middle of the main component is polyvinyl chloride, the bottom is the back coating adhesive. It is the world's favorite, quite popular and also widely used in a synthetic material. Its global use in a variety of synthetic materials in the second. According to the statistics,

PVC can be divided into soft PVC and hard PVC. Which accounted for about 2/3 of the hard PVC market, soft PVC accounted for 1/3 Soft PVC is generally used for the floor, ceiling and leather surface, but because the soft PVC contains softeners (which is the difference between soft PVC and hard PVC), easy to become brittle, easy to save, so its use has been limited. Hard PVC does not contain softener, so flexible, easy to shape, not brittle, non-toxic and pollution-free, long storage time, so it has great development and application value. Hereinafter referred to as PVC. The essence of PVC is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry.

Four, strict process

PVC has been widely used in the building materials industry, there are two very important reasons:

First PVC unique performance (rain, fire, anti-static, easy to shape), the second is the characteristics of low-input high-yield PVC. So why can PVC have these two excellent? Let us from the production process to find the answer to it

PVC production process is not complicated, the general production line generally by the rolling press, printing presses, backcoit machine and cutting machine, mainly through the roller press the direct stirring, roller rotation and high temperature rolling to produce the thickness of only A film of 0.3 mm to 0.7 mm is produced and printed on the front side of the film at the same time and is attached to the back of the film by a backcoaver. Do not underestimate this layer of back coating, it is PVC film quality performance is an important guarantee. Back coat by a special material composition, is a high-energy affinity agent, it is because of this layer of back coating, PVC film can be tightly in the plate or other plate together, ten years or even fifteen years without plastic. And ordinary paste in the biggest problem is unable to solve the problem of film shedding. As the entire production process is in the high temperature (rolling machine temperature reached 220 degrees) carried out, which makes PVC film with high light resistance and fire resistance, to ensure high quality PVC film. Of course, this is very demanding on the production machinery, usually a production line of production equipment cost about 39 million marks, equivalent to about 160 million yuan. But on the other hand, PVC film production process is quite simple, the machine production is also great, so a comprehensive view, PVC is actually a low input, high yield products.

Five, extraordinary performance

PVC foam board: with anti-corrosion, moisture, no water, can not drill, can be sawed, can be planed, easy to thermoforming, hot bending and other characteristics, it is widely used in furniture, cabinets, , The core of the box, indoor and outdoor decoration, building materials, chemical and other fields with the board, advertising signs, printing, silk screen, inkjet, computer lettering, electronic instrumentation products packaging and other industries

PVC hard plastic plate: with excellent corrosion resistance, insulation, and a certain degree of mechanical strength; after the second processing can be made of sulfuric acid (hydrochloric acid) tank (barrel); medicine with empty needle frame, Public toilet water tank; processing products of the template, decorative panels, exhaust pipes, equipment, and other special-shaped products, containers. It is an ideal choice for chemical, building materials, decoration and other industries

Plexiglass: with good weather resistance, impact resistance, high light transmittance, easy to install, plastic and strong characteristics. In the construction, decoration, advertising and other industries have been widely used.