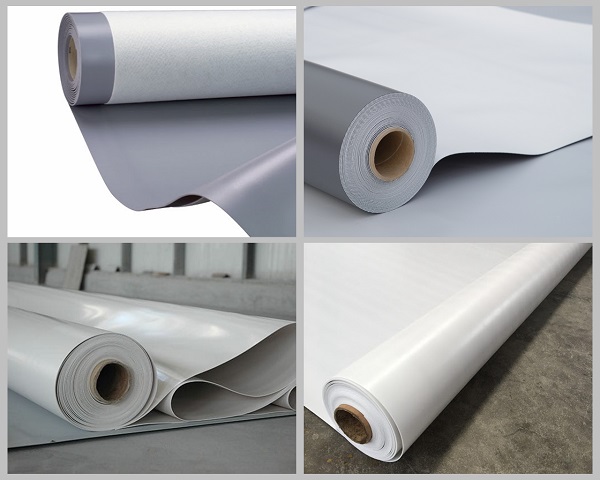

TPO roofing membrane thickness roll

In the early 1990s, mechanically fixed paving was used in roof waterproofing projects. Because it not only has the weather resistance of EPDM rubber, but also has the weldability of plastic waterproofing membrane, the waterproof effect is reliable, and the aging resistance is outstanding, so it has developed rapidly. With its excellent physical and chemical properties and performance, the coil has become the fastest growing waterproof material in the world today. In the United States, TPO waterproofing membranes have accounted for 30% of the American low-slope commercial roofing material market, and maintained an annual growth rate of more than 25%. In recent years, with the development of mechanical single-layer roofing systems, high-performance, energy-saving and effective TPO roofing membranes have also shown a rapid development momentum in China.

Product Spec.:

|

Product Name |

Waterproofing Membrane |

Standard |

GB27789-2011 |

|

Thicknesses |

1.2mm, 1.5mm, 2mm | ||

|

Roll Size |

2M*20M/roll | ||

Data Sheet:

,

|

No. |

Test Item |

Index | |||

|

H |

L |

P | |||

|

1 |

TPO Thickness |

|

|

|

0.4mm |

|

2 |

Strength |

Max peeling strength (N/cm) |

- |

200 |

250 |

|

Tensile Strength (MPA) |

12.0 |

- |

- | ||

|

tensile elongation (%) |

- |

- |

15 | ||

|

Breaking elongation (%) |

500 |

250 |

- | ||

|

3 |

Heat treatment size change rate(%) < |

2.0 |

1.0 |

0.5 | |

|

4 |

Low temperature bending |

-40℃ no cracking | |||

|

5 |

Waterproofing |

0.3MPA, 2hours Impermeable | |||

|

6 |

Impact resistance |

0.5KG.m, Impermeable | |||

|

7 |

Static loading |

|

|

20KG | |

|

8 |

Peeling Strength (N/cm) |

4.0 |

3.0 |

3.0 | |

|

9 |

Tearing strength (N/cm) |

60 |

250 |

450 | |

|

10 |

Water absorption(70℃, 168h, %) < |

4.0 | |||

|

11 |

Heat aging 115℃ |

Time(H) |

672 | ||

|

Outlook |

No bubble, cracking, hole, etc | ||||

|

Max peeling strength remain |

90% |

90% |

90% | ||

|

elongation (%) |

90% |

90% |

90% | ||

|

Low temperature bending |

-40℃ no cracking | ||||

|

12 |

Chemical Resistance |

Outlook |

No bubble, cracking, hole, etc | ||

|

Max peeling strength remain |

90% |

90% |

90% | ||

|

elongation (%) |

90% |

90% |

90% | ||

|

Low temperature bending |

-40℃ no cracking | ||||

|

13 |

Anti-Aging |

Time(H) |

1500 |

|

|

|

Outlook |

No bubble, cracking, hole, etc | ||||

|

Max peeling strength remain |

90% |

90% |

90% | ||

|

elongation (%) |

90% |

90% |

90% | ||

|

Low temperature bending |

-40℃ no cracking | ||||

Main advantages:

1. Long service life, aging resistance, TPO roofing materials can be used for more than 20 years, underground can be up to 50 years.

2. High tensile strength, high elongation, small change in heat treatment size.

3. Good flexibility at low temperature, adapt to small changes in environmental temperature.

4. Good root penetration resistance and can be made into planting roofs.

5. Good perforation resistance and impact resistance.

6. Convenient construction, less wide lap joints, weldable, firm and reliable.

7. Strong chemical resistance, suitable for special occasions.

8. It has good plasticity, and it is convenient and quick to handle the details of the corners.

9. Convenient maintenance and low cost.

10. The light-colored surface reflects ultraviolet radiation; the surface of the coil absorbs less heat and the temperature is low.

11. The coil has good water vapor diffusivity, the condensate is easy to release, and the moisture and moisture remaining in the base layer are easy to discharge.

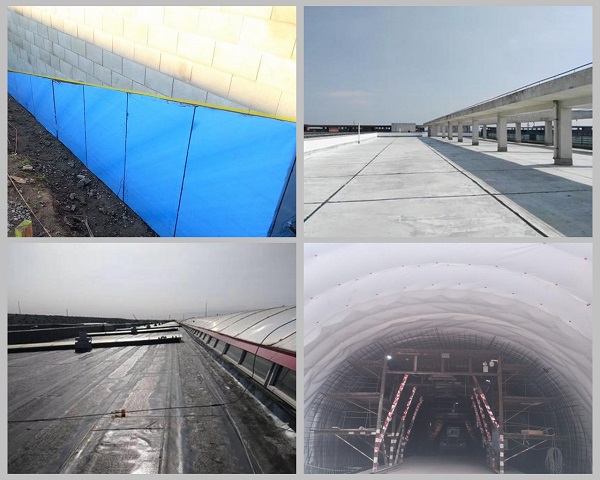

Applications:

TPO membranes are Suitable for roof waterproofing of industrial and civil buildings, including planted roofs, flat roofs, sloped houses;

underground waterproofing of buildings: waterproofing of reservoirs, pools, canals and basements; tunnels, grain depots, civil air defense projects, landfills, artificial Lake and other waterproofing.

Installation Instructions

Combined with the characteristics of TPO sheet membrane rolls, cold bonding, empty laying, mechanical fixing and sometimes a unique hot air welding process are used. Complicated waterproof construction parts should be specially matched. TPO special accessories combined construction.

Cold bonding method: The construction method of using a special adhesive for TPO coils to paste the coils on the base layer by cold work is called cold bonding. According to different waterproof design requirements, the cold bonding method can be divided into full bonding or partial bonding.

DERFLEX continues to research and develop new products for each market, continuously improving the customers' competitiveness.

V.Our main product is PVC tarpaulin and it is widely used as truck/trailer/container cover, tents, pallet cover,strip garden fence,

awnings, inflatable products, adumbral materials for building facility and house.

For further business communication, welco, me to contact:

Judy.ye

Tel: +8613761310496(whatsapp&wechat)

Email: judy.ye@derflex.com

Web: www.derflex.com