reflective vinyl category: Retroreflective & Prismatic

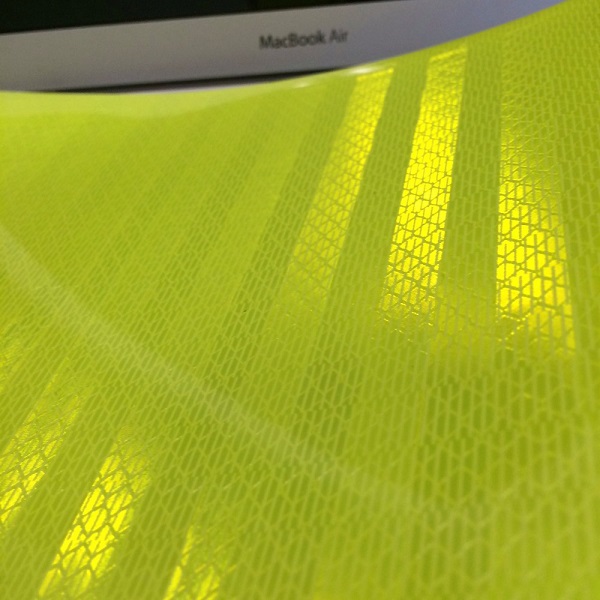

Not all reflective vinyl is the same. There are two basic kinds, usually characterized as retro-reflective, and prismatic reflective. These are further segmented into different Types and grades determined by their construction and reflective properties, which we’ll examine in a moment. Retro-reflective is made by mixing glass beads in the pigment of the face film. The embedded beads reflect light back toward the viewer when illuminated. Therefore retro-reflective film is also referred to as beaded reflective.

These embedded beads make retro-reflective sheeting more difficult to cut than standard PVC vinyl. Always use a 60o blade when cutting retroreflective sheeting. You can make it work with a 45o blade and lots of force, but that blade will be worthless when you’re done.

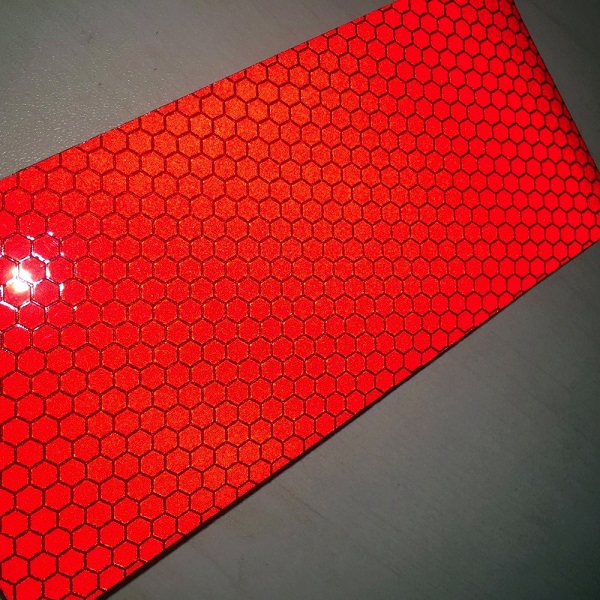

Prismatic reflective film is made by layering small prisms in the face film. Upon close inspection these would look like tiny pyramids in the vinyl. Just as a prism splits and reflects light, prismatic reflective film reflects light back through the face film toward the viewer.

This densely layered construction makes prismatic reflective sheeting even more difficult to cut than retro-reflective film. Some brands Diamond Grade, can only be cut with a Pro Series cutter using special blades and well over 400 grams of force. If your vinyl is wider than 24″, you may need to add a pinch roller to your plotter. The amount of cutting force applied to cut the film can cause tracking problems. Extra pinch rollers help keep the media aligned properly.

Crystal Grade reflective cannot be cut with anything less than a flatbed cutter. It can be scored with a Pro Series plotter, but the cutting must then be finished by hand.

The advantage of prismatic film is that the sides of the prismatic cells in the face film bounce light back at wider angles. This results in much more light being reflected back toward the source and makes the light visible from a wider viewing angle. This is especially useful in highway signs, which is why prismatic sheeting is the specification for this application.