DERFLEX heavy duty PVC tarpaulin fabric advantages

I: What is PVC Tarpaulin Fabric

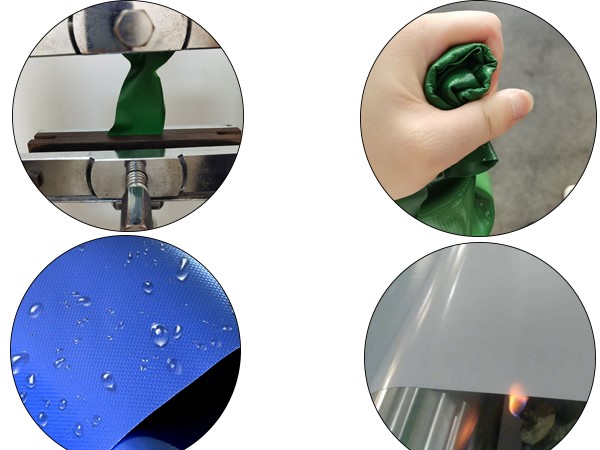

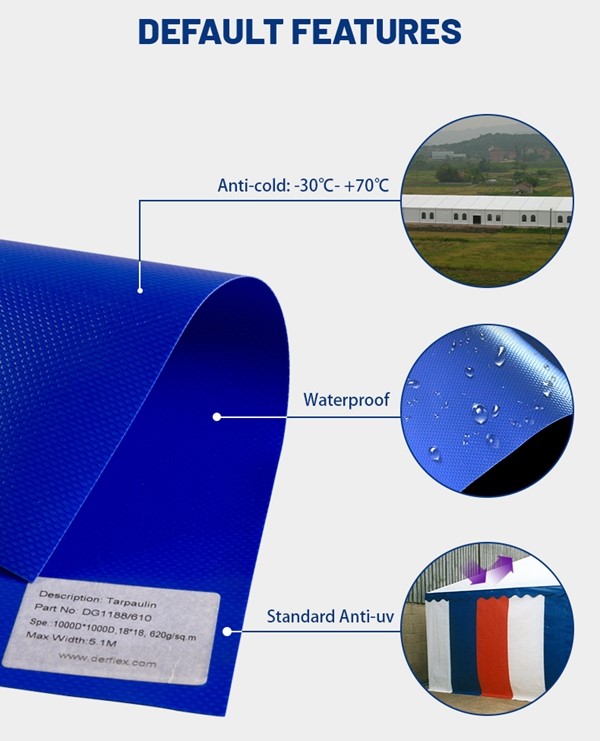

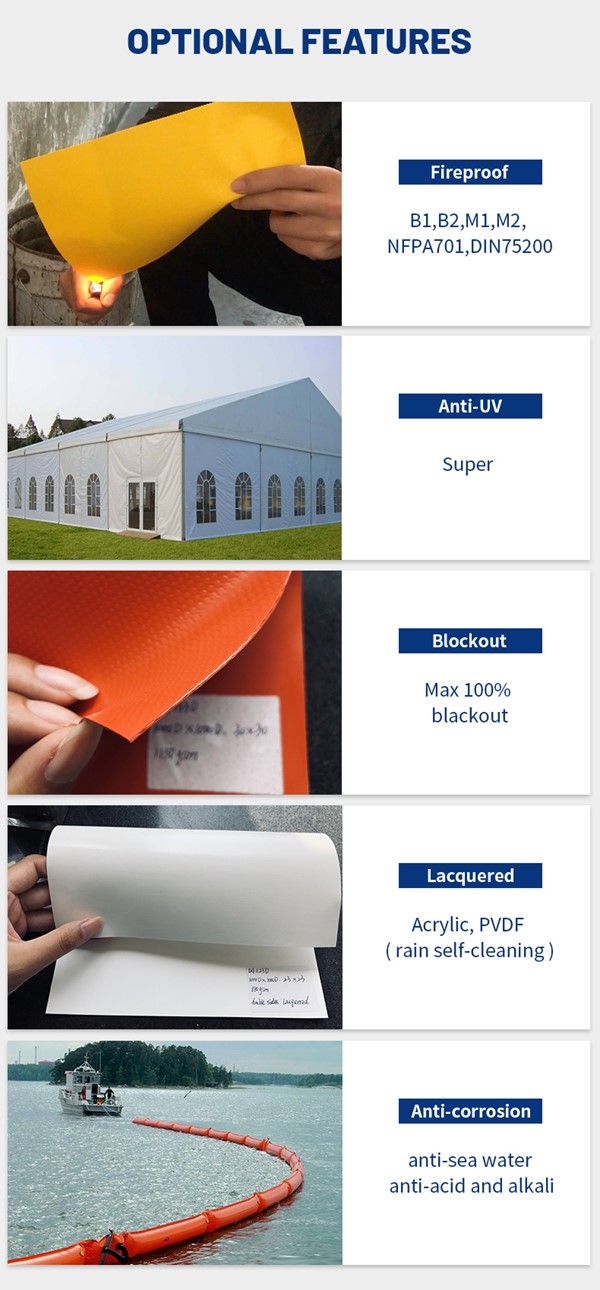

PVC tarpaulins, car tarpaulins, waterproof tarpaulins, plastic tarpaulins are made of high strength polyester high-strength polyester canvas fabric, coated with polyvinyl chloride (PVC) paste resin with addition of variety of chemical additives, like DOP, anti-aging and anti-static components, etc.. It has waterproof, anti-mildew, anti-cold, anti-aging, anti-static properties; and the product breaking strength, tearing strength, elongation rate is much better than traditional tarp; Different colorful appearance, very enjoyable. Special surface treatment anti-slip effect, is a popular international waterproof cloth, and maximum width up to 3.20 meters, can reduce the joint and improve the quality of the finished product during processing. It can be easily hot welded, 100% waterproof. Different functions, different colors, different thickness of the product can be produced according to clients’ request.

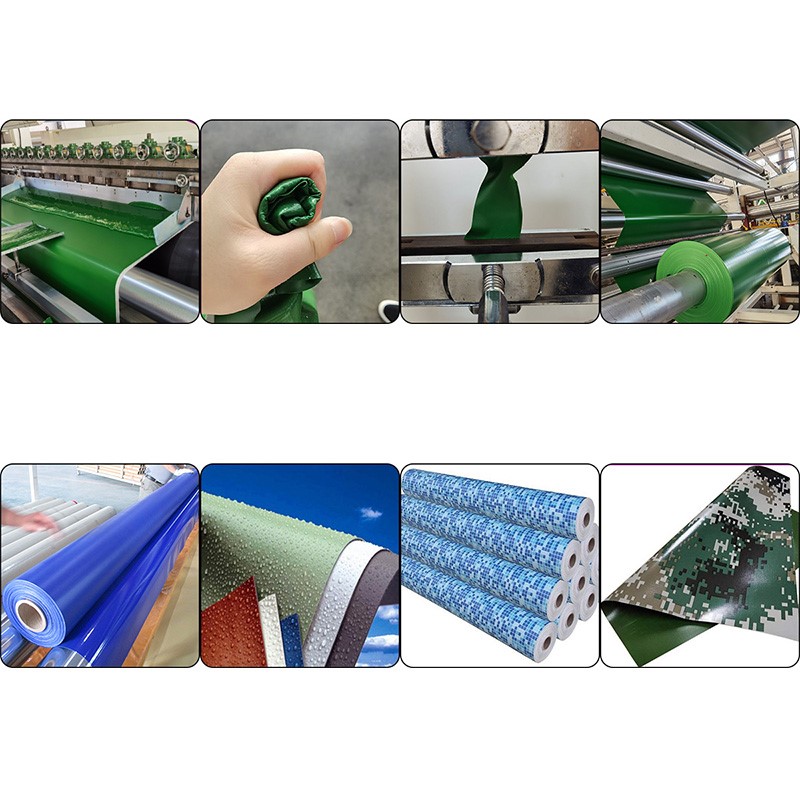

II: DERFLEX hot melt pvc tarpaulin

This is a polyester fabric laminated with PVC film both sides. Before lamination, the fabrics is passed through the glue, to make the heavy-duty PVC tarpaulin better adhesion.

This method is used for thermoplastic polymers such as polyurethane, polyolefins and PVC, which are applied by feeding granules of the material into the nip between moving heated rollers. There are two general designs in use, the Zimmer machine, which has two melt rollers the Bema machine, which has three. They are smaller version of calenders but differ in that they need a fabric (or paper or a film) as a substrate on which to deposit the film as it is produced. This method can apply resin (in the form of films) to fabric at a faster rate than that can be achieved by transfer coating or direct coating. This process is used to produce light weight coverings or tarpaulins.

III : DERFLEX PVC Coated Tarpaulin

PVC coating is a production process. Liquid PVC is poured onto the chemical fiber cloth, and the liquid PVC is evenly coated and scraped on the surface of the chemical fiber cloth with a baffle similar to the blade, and then dried and shaped to become the final PVC tarpaulin.

IV:DERFLEX hot melt and knife coated pvc tarpaulin different advantages

Comparation between knife coating and hot melt

|

ITEMS |

Knife coated PVC |

Hot met PVC |

|

Breaking strength |

√ |

○ |

|

Adhesion |

√ |

○ |

|

Outdoor Durance |

√ |

○ |

|

Water resistance |

○ |

√ |

|

Air tightness |

○ |

√ |

|

Main applications |

Outdoor covers, tents, container bag, ventilation tube, etc… |

Flexible water tank, inflatable castles, etc… |

V: Hot melt and knife coated pvc tarpaulin different applications

a: hot melt pvc tarpaulin are widely used for outdoor covers, vehicle covers material, vehicle cover tarpaulin, PVC vehicle cover fabric, PVC vehicle cover tarpaulin tent, container bag, ventilation tube etc.

B: knife coated pvc tarpaulin are mainly used for flexible water tank, inflatable castles and boats etc.

Features: hot melt and knife coated pvc tarpaulin are both with excellent following features:

a. Water-proof;

b. Anti-UV;

C: Outstanding tearing strength

D. Good peeling strength for welding.

E. Anti-fire;

F: Actylic treatment(optional)

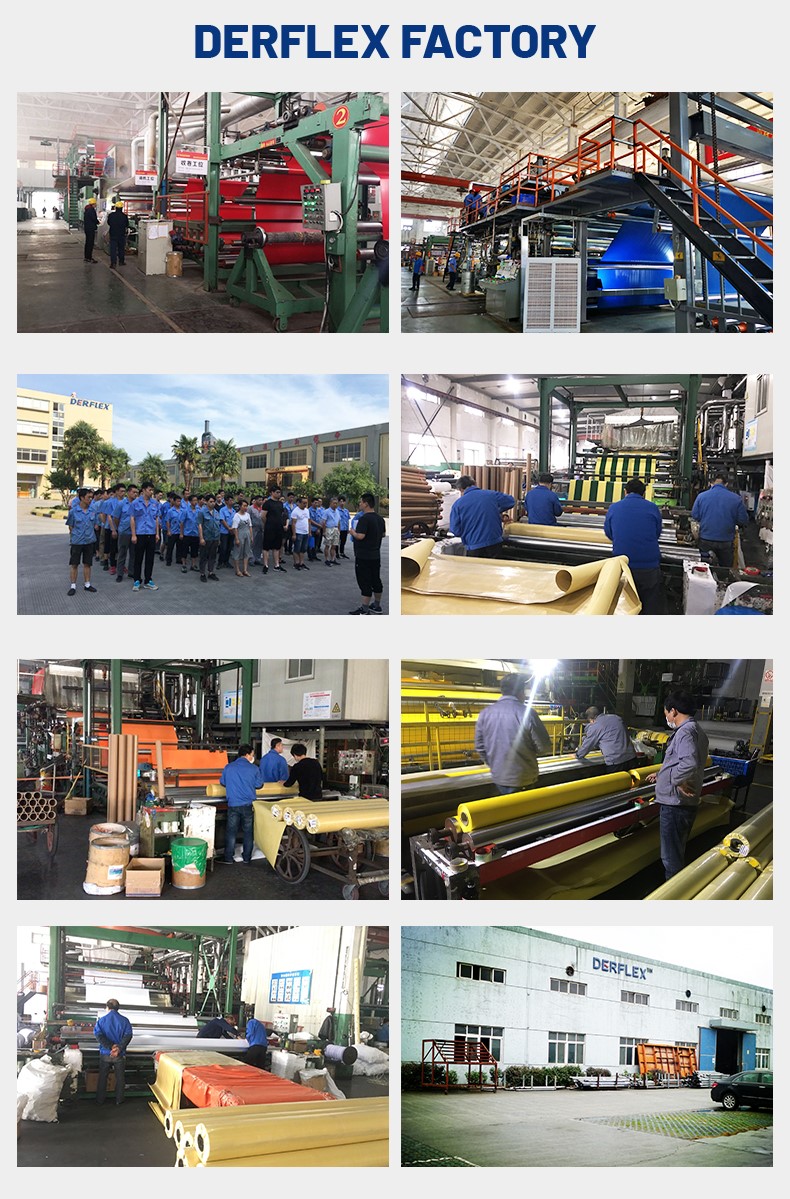

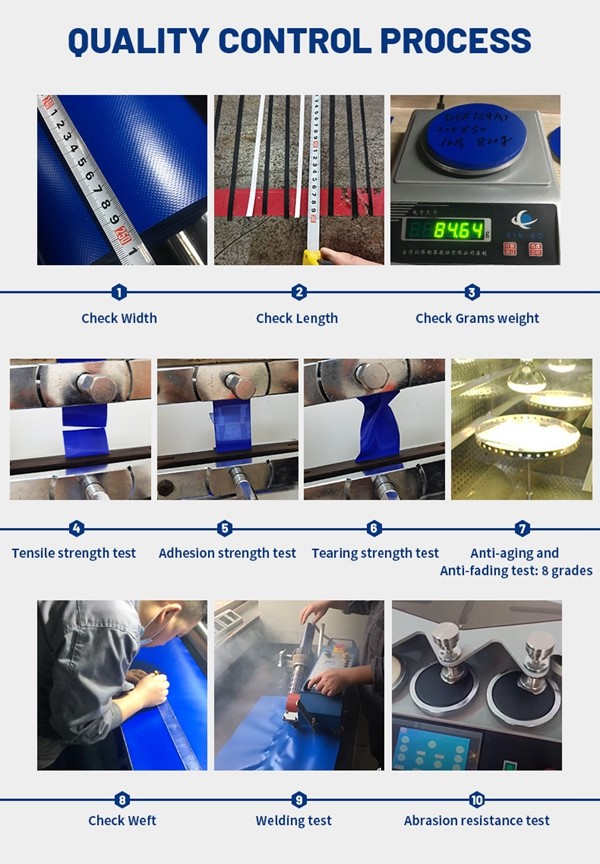

VI: About Derflex

DERFLEX is one of the oldest professional PVC tarpaulin manufacturer in China for more than 20 years. We have strict quality system and we focus on manufacturing and exploring PVC coated fabrics.

For more information, welcome to reach us at Ann Li( What”s APP&Wechat:+86-187-0192-0943 E-mail: ann@derflex.com