What is TPO Waterproof Membrane

I.What is TPO Waterproof Membrane ?

TPO is acronymous for Thermoplastic Polyolefin and it is a type of polymer single-ply membrane that uses thermo-welding (hot air) to connect the seams. This type of membrane was originally developed in the 80's and it is currently the fastest growing membrane in the roofing and waterproofing industry.It is a kind of thermoplastic elastic laminated waterproof material , which is made of TPO resin by Chemical copolymerization with specific formula .It is the best materials using for single-ply roof waterproofing.

II. TPO Waterproof Membrane is divided into different types:

Homogeneous TPO membrane,Reinforced TPO membrane,Self Adhesive TPO membrane,Fabric Backing TPO membrane

III. What are the advantages of TPO?

1.Compared with another type of membranes, TPO combines several advantages like the fact that it doesn’t contain any toxic or hazardous ingredients and therefore environmentally friendly, or its heat-reflective characteristics make it highly energy efficient.

2.Also, the TPO membranes are fully recyclable, so the impact on the environment is very low, but one of the best features is the fact that TPO doesn't contain plasticizers to be flexible, such as PVC membranes. The polyolefin structure is flexible and it will stay flexible throughout its total life cycle, having unique benefits on the durability of the membrane.

IV.Product Features

1.Strong aging resistance and stability .

2. Excellent environmental friendly performance .No chlorine ,no pollution .

3. High performance in breaking strength, tearing strength and puncture resistance

4. Good flexibility at low temperature,no crack at -40℃

5.Smooth surface with high light reflection rate which result in energy saving and pollution resistant

6.Anti-Microbiological growth, Stable size with heat aging resistance

7.Strong Chemical resistance to acid and alkali

8.High Security without open flame installation

9.Service Life: Exposed using min 20 years ; if unexposed , it can be 50-100 years .

10.TPO raw materials: polypropylene (PP) and (EPR including EPM and EPDM ) Our TPO resins Hifax made by the Catalloy process of Lyondellbasell co., LTD from Netherlands , and we used the method of copoymerization in polymerization to produce the TPO membrane with uniform distribution and small distribution size And Features of high elasticity, wide welding window, fixed installation without perforation.

11.The welding window of TPO coil is wide.

12.The artificial weathering time of DER TPO is not less than 6500 hours.

V.Technical Data Standard Sheet rd Sheet (GB27789-2011)

|

No. |

Test Item |

Index | |||

|

H |

L |

P | |||

|

1 |

The thickness of resin layer above the reinforcement fabric/ mm ≥ |

- |

- |

0.40 | |

|

2 |

Tensile property |

Maximum Tension N/cm ≥ |

- |

200 |

250 |

|

Tensile Strength Mpa ≥ |

12.0 |

- |

- | ||

|

Max Tension Elongation/ % ≥ |

- |

- |

15 | ||

|

Breaking Elongation/ %≥ |

500 |

250 |

- | ||

|

3 |

Heating treatment size change rate % ≤ |

2.0 |

1.0 |

0.5 | |

|

4 |

Low temperature bending |

-40 ℃ No.Crack | |||

|

5 |

Water impermeability |

0.3Mpa, 2h Impermeable | |||

|

6 |

Impact resistance |

0.5kg, m ,impermeable | |||

|

7 |

Anti-static load |

- |

- |

20kg impermeable | |

|

8 |

Seam peel strength N/mm ≥ |

4.0 |

3.0 |

3.0 | |

|

9 |

Right -angle tear strength N/mm ≥ |

60 |

- |

- | |

|

10 |

Trapezoid tear strength N ≥ |

- |

250 |

450 | |

|

11 |

Water absorbing capability (70 ℃, 168h)%≤ |

4.0 | |||

|

12 |

Heat aging (115 ℃) |

Time/h |

672 | ||

|

Appearance |

No bubble ,crack ,delamination , bonding and holes | ||||

|

Max tensile retention %≥ |

- |

90 |

90 | ||

|

Elongation retention % ≥ |

90 |

- |

- | ||

|

Tensile strength ( Max tension on )retention %≥ |

- |

- |

90 | ||

|

Breaking elongation retention /%≥ |

90 |

90 |

- | ||

|

Cold bending |

-40 ℃ No. Cracking | ||||

|

13 |

Chemical resistance |

Appearance |

No bubble ,crack ,delamination , bonding and holes | ||

|

Max tensile retention %≥ |

- |

90 |

90 | ||

|

Elongation retention % ≥ |

90 |

- |

- | ||

|

Tensile strength ( Max tension on )retention %≥ |

- |

- |

90 | ||

|

Breaking elongation retention /%≥ |

90 |

90 |

- | ||

|

Cold bending |

-40 ℃ No. Cracking | ||||

|

14 |

Artificial Climate accelerating aging |

Time/h |

1500 | ||

|

Appearance |

No bubble ,crack ,delamination , bonding and holes | ||||

|

Max tensile retention %≥ |

- |

90 |

90 | ||

|

Elongation retention % ≥ |

90 |

- |

- | ||

|

Tensile strength ( Max tension )retention %≥ |

- |

- |

90 | ||

|

Breaking elongation retention /%≥ |

90 |

90 |

- | ||

|

Cold bending |

-40 ℃ No. Cracking | ||||

|

Single-ply roof membrane artificial climate accelerating aging time is 2500h | |||||

VI.Standard Specification

1.Width : 2.0m , 2.5m

2.Basic Thickness : 1.2mm , 1.5mm, 1.8 mm ,2.0mm

3.Length: 20m

VII.Scope of Application:

Convention centers , exhibition halls ,stadiums , library , airport terminals , industrial plants,warehouse , logistics and other building’s metal roofs , exposed concrete roofs and green roofs.

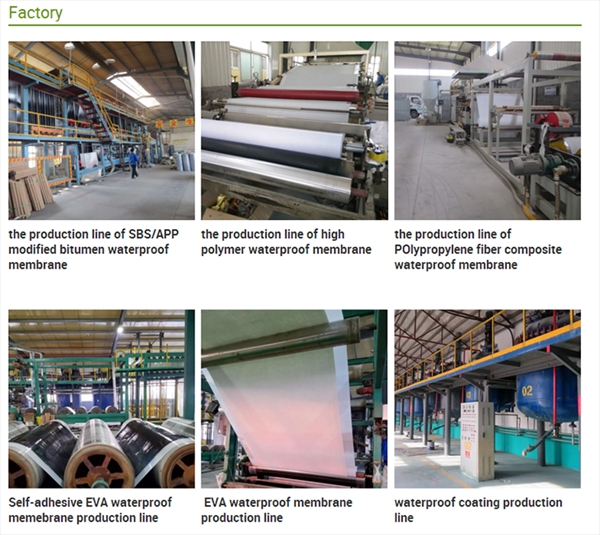

VIII.Our Factory

Derflex is one of the leading TPO Waterproof Membrane manufacturers in China with a history of 20 years. For more information please contact me:

Email: serena@derflex.com

Tele: +86 130 1285 4064 (WhatsApp and WeChat)

Facebook ID: https://www.facebook.com/serenazhu0809/