What is a PTFE venting membrane

I: What is PTFE venting membrane

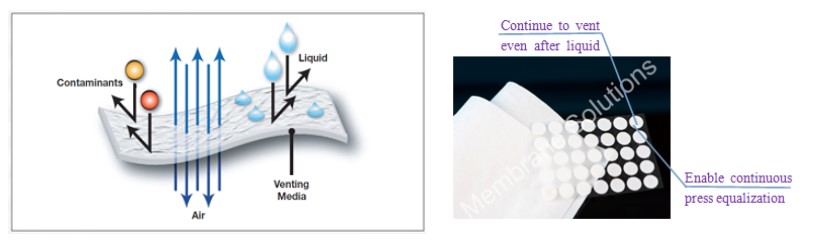

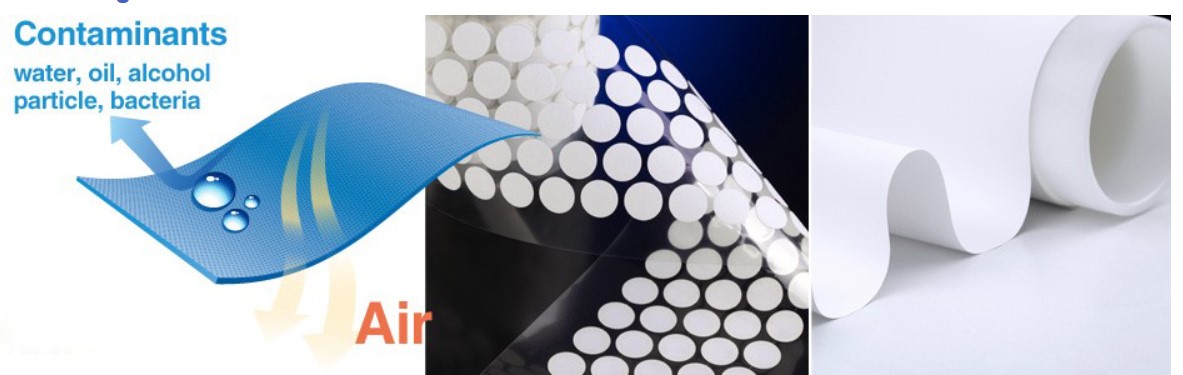

PTFE venting materials have had a big impact on the product marketplace. Many industries benefit from the inherent properties of a PTFE membrane filter, including automotive, medical, industrial and even the mining industry. This microfiltration membrane can be leveraged for its hydrophobic or oleophobic properties. In the automotive industry, headlamps require outgassing capabilities to create a breathable headlamp chamber that ensures no condensation on the interior of the housing. A hydrophobic PTFE membrane filter is perfect for this type of environment because it allows air to flow through which depressurizes the chamber while still repelling water.

Automotive parts manufacturers also rely on its oleophobic properties. While oil is used to keep an engine running properly, there are areas where they do not want oil to contaminate. Having a PTFE membrane filter ensures the proper environment is maintained.

II: Features:

TFE venting products, whether a hydrophobic ptfe membrane filter or one with oleophobic properties, allow effective ptfe venting to manage differential pressure, prevent leakage or contamination and allow a high level of airflow while resisting water or oil as necessary.

• Prevents leakage

• Allows a high level of airflow (even after liquid contact)

• Prevents contamination and maintains environmental purity

• Is safe to use with most chemicals

• Resists low surface tension substances

• Integrates easily into most manufacturing processes

III: Specifications & Details:

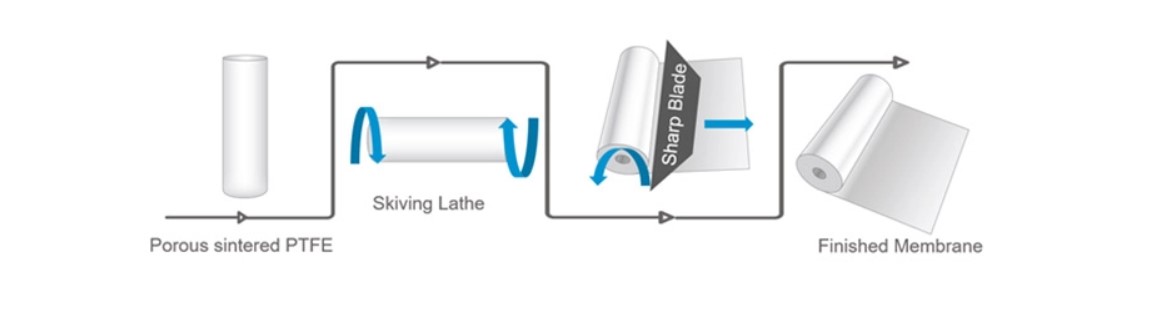

Polytetrafluoroethylene (PTFE)

For applications in need of ultra-hydrophobicity, high temperature tolerances, high chemical resistance, and excellent robustness, sintered and skived PTFE membrane technology is a perfect choice.

Using our wide range of application-specific products, we work closely with your engineering team to define your specifications, and they can help select the best PTFE membrane for your application.

When incorporating a sintered PTFE membrane into your product, it’s critical to understand several physical properties as they impact the materials and functionality of the part:

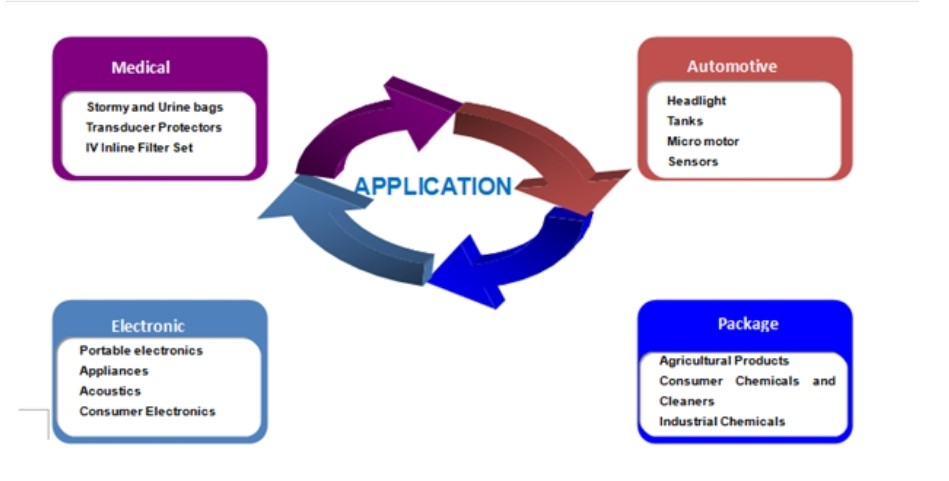

IV: Applications

V: Advantages of PTFE Venting Membrane:

• Air flow rate: This is the desired air flow rate at a given pressure drop through a specific area. This is a critical measure for designing a venting membrane. One important thing to note – air flow rate will increase through the same vent as the ΔP increases.

• Water entry pressure (WEP): This is the amount of water pressure required to have water break through the membrane. This is a critical measure when designing a water-resistant venting or filtering membrane.

• Operating temperature: Operating temperature defines the temperature range at which the part will be required to operate. For PTFE membrane, this value is 260 °C continuous.

• Other key characteristics: PTFE membrane is an extremely versatile material that is used in numerous markets and applications. Other application-specific characteristics can include filtration efficiency, moisture vapor transmission rate, Gurley number, % reflectivity, and dielectric properties that may be required for your application.

VI: About Derflex:

DER New Material is one of the leading China high-quality PTFE venting membrane manufacturers and suppliers, with professional factory, we are able to produce high-quality high-quality pvc coated fabric architectural membrane at competitive price, and we can always offer you products for sale. Welcome to wholesale products from us.

Welcome to reach us at Ann Li with What”s APP&Wechat:+86-187-0192-0943 E-mail: ann@derflex.com