What is the best material for drinking water storage ?

Ⅰ,What is the material for drinking water storage ?

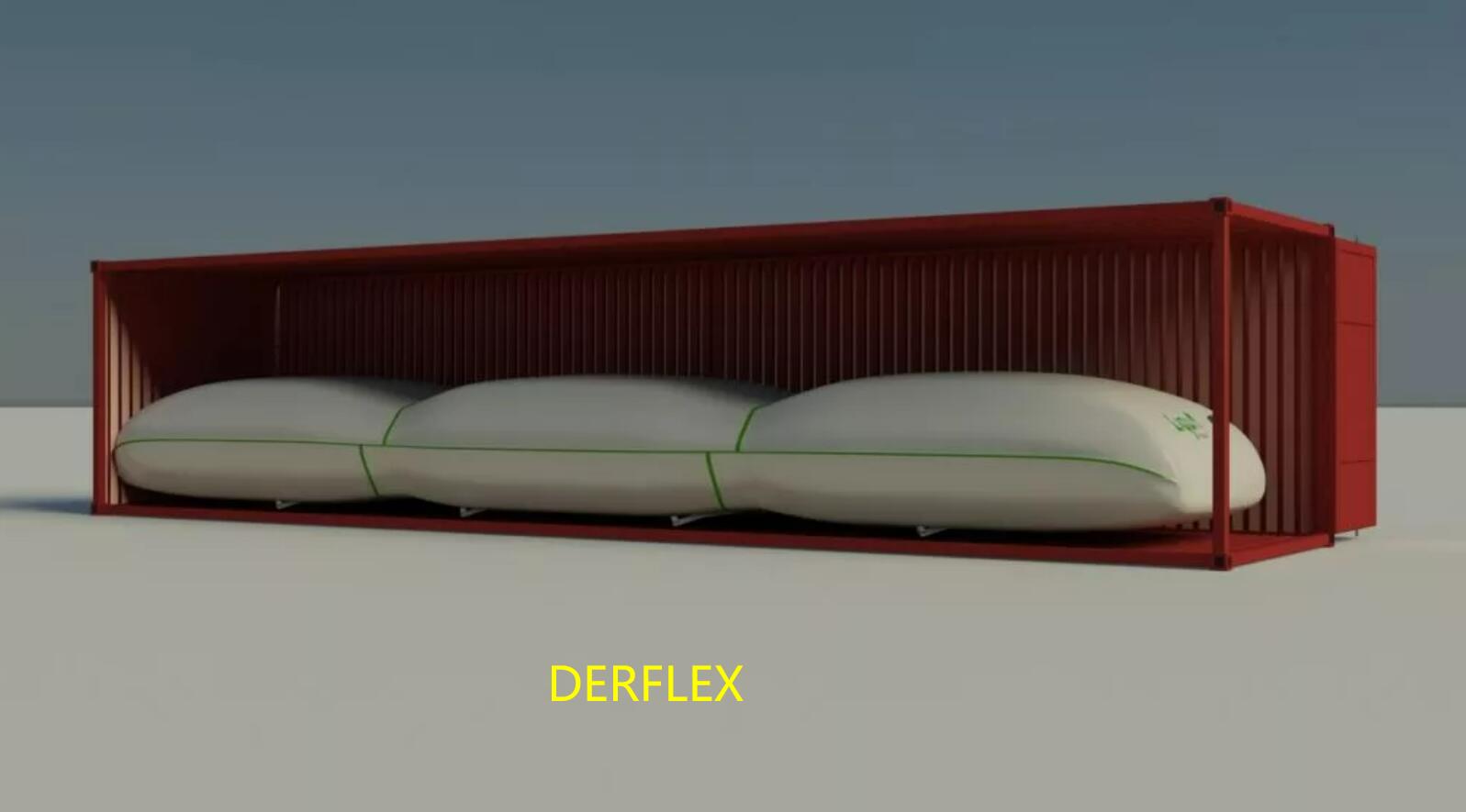

The material for drinking water (TPU water bag ) is made of TPU coated polyester fabrics, especially used for storage of alcohol, food additives, fruit juice concentrates, liquids, mineral water, sorbitol, soy sauce, vinegar, malt, various kinds of sugar water, etc.

Ⅱ,TPU water bag fabric characteristics:

1. Water resistance: that is, after the action of water and infiltration by water, the properties of the crucible are basically unchanged, and it is impervious to water under the pressure of water.

2. Temperature stability: no flow, no blistering, no sliding at high temperatures; no brittleness at low temperatures. It can also be considered as the ability to maintain the original performance under a certain temperature change.

3. Mechanical strength, extension boat fracture resistance: Does not break under the load stress and deformation conditions within the allowable range of the building structure.

4. Flexibility: Special requirements for waterproof material with low temperature flexibility, to ensure easy construction, not embrittlement.

5. Atmospheric stability: The ability to resist aging and resist erosion under the long-term comprehensive effects of sunlight, heat, oxygen, and other chemically eroding media and microbial erosion media.

Ⅲ,TPU water storage fabric

Weight:1500gsm

Thickness: 1.2mm

Base Fabric: 1000Dx1000D 30x30

Width:1.02---3.2M

Max Elongation Strength:4137/3704 N/5cm

Tear Strength: 413/408 N

Peel Strentgh:130 N/5cm

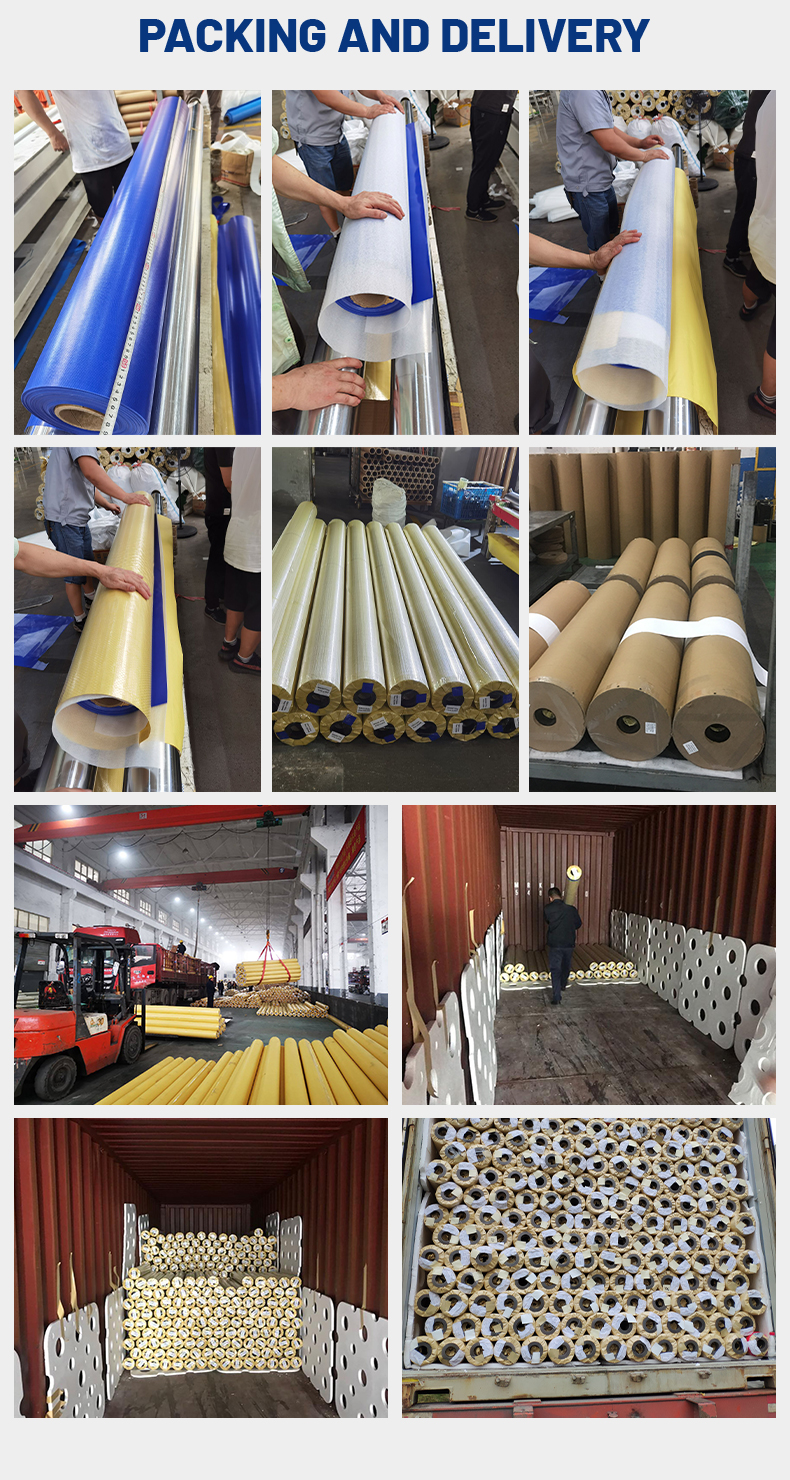

Ⅳ, Packaging of TPU coated fabric:

Pearl cotton film for waterproofing;

hard tube with 5 paper layers, to avoid damage during transportation;

Customized Logo printing for free;

Foam pad taken before loading the container;

Plastic covering on both side of the tube, more firm

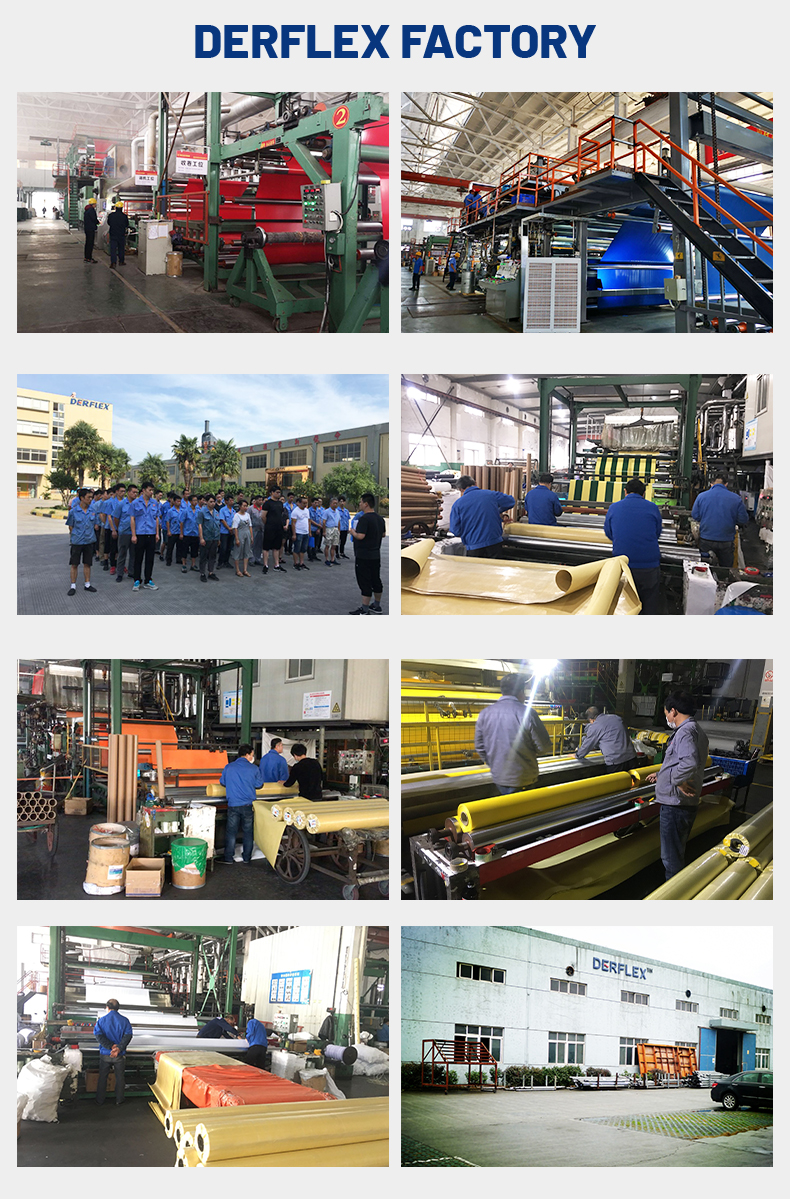

Ⅵ, About DERFLEX China:

1.Quality assurance: We will 100% return money if any quality problem, our QC department will inspect each order

before ship.

2.Experience: 20 years’ R&D and production experience.

3.Production area: 60,000 square meter, 20 senior engineers and 350 workers.

4.International exhibition: Every year we attend USA, Germany, Russia, Spain international exhibitions etc.

5.Product quality: Our enhanced products are products that combine European and American quality standards.

DERFLEX Production Lines

1. Knife coating production lines to make High adhesion coted fabrics, the high adhesion makes higher outdoor durance and Anti-UV characters

2. Hot-melt coating production line: With high water-resistant and water tight and air tight characters, which can make inflatable products

DERFLEX is exporting to more than 100 countries all over world.

Professional Sales and After-sale survice;

Experienced production team;

Good reputation on quality control;

Immediate response to customers' questions

Makes DERFLEX stronger business range on PVC coated fabrics industry, which can compete >95% products from other factories

Quality control

DERFLEX coated fabrics quality control process

During Production:

1. Online raw material quality control

2. Online surface flatness control

3. Online defects inspection

4. Online weight control

5. Fabric Structure

After production:

1. Roll Width

2. Roll Length

3. final product weight

4. tearing strength

5. breaking strength

6. adhesion

7. Aging test

8. Welding test

9. Abrasion test

10: Check fabric structure.

Contact :

Sales manager: Masha

Cell Phone:+86-131 6285 8753(What"s App&Wechat)

Email: masha@derflex.com