What is inflatable tubes fabric made of

What is inflatable tubes fabric made of?

I Introduction for inflatable boat tubes fabric

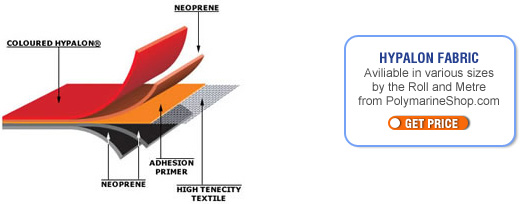

Hypalon and Neoprene Coatings (Synthetic Rubber Coatings):

Hypalon is a synthetic rubber material patented by DuPont. Hypalon has many applications in many industries and it has proven itself as a material with excellent air holding capabilities and oil resistance. Hypalon coated onto polyester or nylon fabric with an interior coating of neoprene a very reliable and durable inflatable boat fabric and can last for more than a decade even in the harshest environments – which is the reason for warranties of five and 10 years.

1 Hypalon Construction:

The seams in Hypalon boats are either overlapped or butted, and then glued. Butted seams produce an aesthetic, flat, airtight seam, without the ridge or air gaps left by some overlapped seams. However, butted seams are more labor-intensive, thus the boats are usually more expensive. It is always wise to look for an inflatable boat with seams that are double-taped, and are glued on both sides. In stress tests, Hypalon and neoprene glued seams are so strong and reliable that the fabric will fail before the seams.

2 PVC Construction:

The seams of PVC-coated inflatables can be fused together using several different welding techniques. Some manufacturers use either high heat pressure, radio frequencies (RF), or electronic welding. Large, specially developed welding machines must be used to fuse the fabric together. Again, this makes it easier and faster to produce PVC-coated boats, especially over handcrafted Hypalon boats.

II Comparison between two kinds of inflatable tubes vinyl fabric

1 Hypalon fabric

Hypalon is a trademark for a series of chlorosulfonated polyethylene (CSPE) synthetic rubbers (CSM) made by DuPont Dow Elastomers.

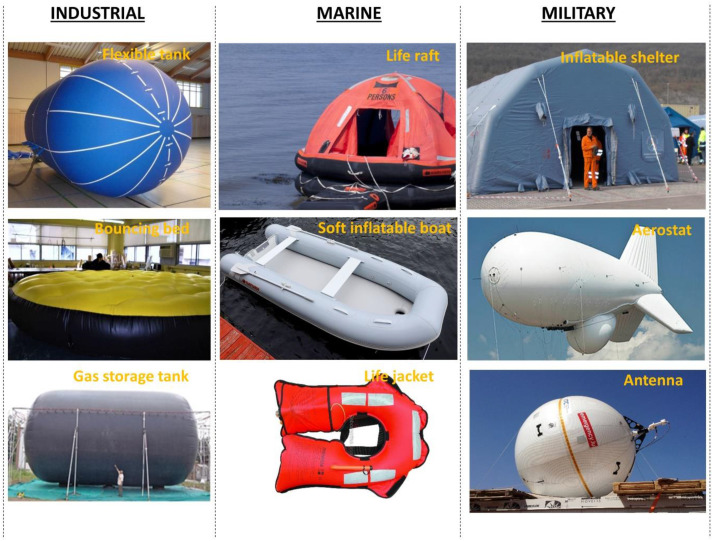

It has many known applications in a range of industries due to its excellent air holding capabilities and outstanding resistance to the deteriorating effects of temperature extremes, ozone, oxygen, weather, oil, and chemicals.

2 PVC fabric

PVC, or polyvinyl chloride, is a synthetic plastic polymer. It is known to be significantly less expensive than Hypalon. It has so many applications ranging from house siding, sewage pipes to furniture, toys, and of course, inflatable boats.

In preparing inflatable PVC boats for the water, chemicals such as plasticizers and stabilizers are added to the boat fabric. While these chemicals improve the boat’s performance, they are not environmentally friendly and they tend to leach out over time.

An inflatable boat made from PVC fabric is a good choice if you are looking for a less expensive boat. You just must keep in mind that inflatable PVC boats may not last as long as some of the higher priced ones.

III Pros for different kinds of inflatable tubes vinyl material

Hypalon fabric pros

1 It has excellent resistance to abrasion and other mechanical abuse.

2 It is unaffected by extreme temperatures and ultraviolet light, so it won’t harden even if left out in the sun.

3 It is highly resistant to oil and a wide range of harsh chemicals which means spilling fuel or oil in it won’t be much of a deal.

4 It doesn’t get brittle and deteriorate over time.

5 Repairing it is rather easy as you can apply a patch while in the field.

PVC fabric pros

1 PVC is the most economical choice of material for inflatable boats.

2 It makes a more lightweight and portable inflatable boat.

3 Because it is a type of plastic, the seams of inflatableb PVC boats can either be glued or thermobonded.

4 It comes in a wider array of colors compared to Hypalon.

IV Cons for different kinds of inflatable tubes fabric

Hypalon fabric cons

1Since it is the most expensive coated material, inflatable boats made from Hypalon are priced much higher than boats made from PVC.

2 It gets dirty more easily because of its porous finish.

3 It is more labor intensive as it should be cold glued by hand.

4 Its color fades when left out in the sun.

PVC fabric cons

1 When dry, PVC is not resistant to abrasion.

2 Compared to Hypalon, it does not respond well to extreme temperatures.

3 It is also not resistant to the deteriorating effects of chemicals, ultraviolet right,

4 Inflatable PVC boats deteriorate over time, so they have shorter life cycle.

V Introduction for DERFLEX

DERFLEX is a professional manufacturer of . We have our own factory, which is located in Zhejiang province, China , with 7 production lines, the supply capacity is 300,000sqm/month. We can produce different kinds of wide format digital printing media. Such as coated Frontlit, backlit, laminated PVC tarpaulin, blockout,mesh,self-adhesive vinyl, one-way vision, perforate vinyl, wide format print cotton canvas, PVC coated tarpaulin, photo paper, reflective material, projection screen fabric.

Our main product is PVC tarpaulin and it is widely used as truck/trailer/container cover, tents, pallet cover,strip garden fence,

awnings, inflatable products, adumbral materials for building facility and house.

For further business communication, welcome to contact:

Tel: +8617316447897(whatsapp&wechat)

Email: ellaine@derflex.com

Web: www.derflex.com