How to test Fiber Based Rigid Inflatable Boats Fabric

How to test Fiber Based Rigid Inflatable Boats Fabric

I: What are the types of Rigid inflatable Boats Fabric

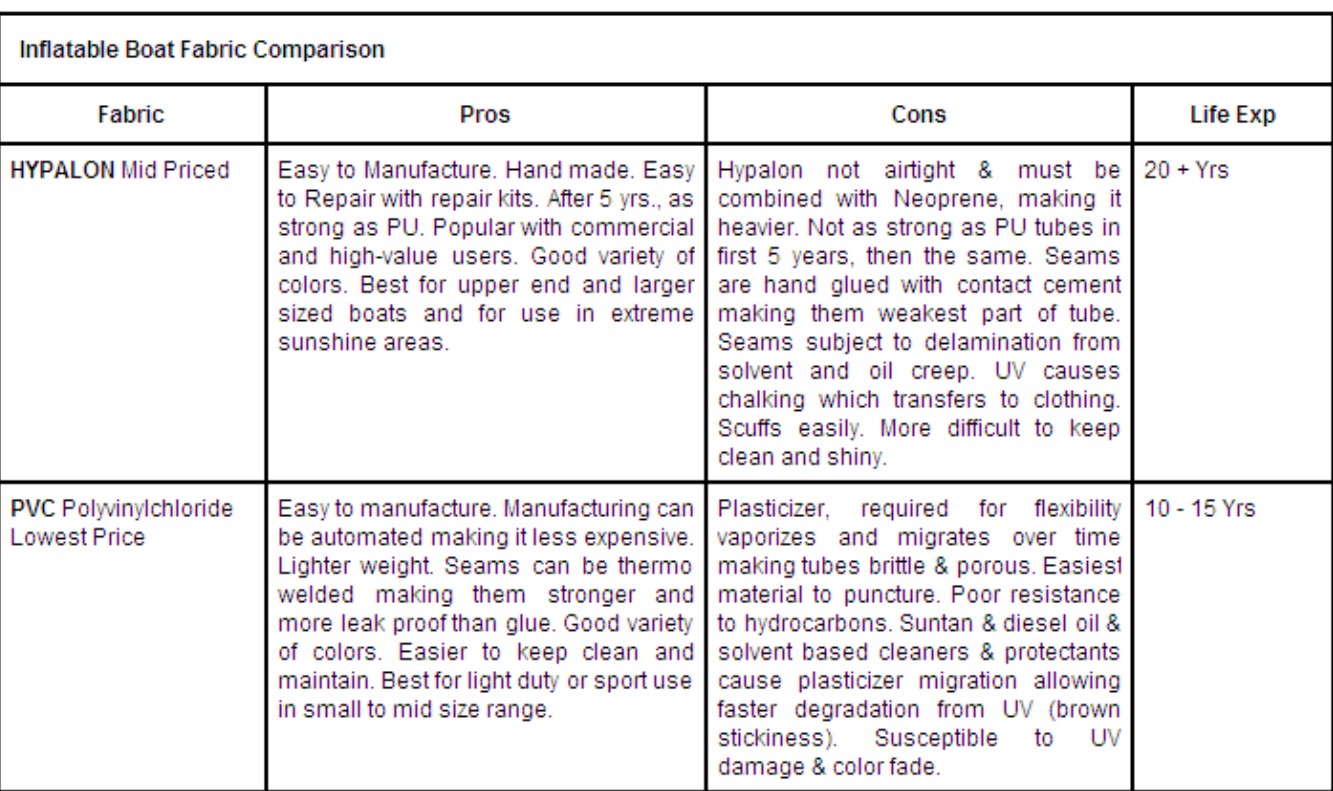

Inflatable sport boats fabrics mainly divides into 3 different categories: Polyvinyl Chloride (PVC) fabrics, Hypalon fabrics or Polyurethane (PU) fabrics. All 3 boat fabrics are made by a coating polymer (PVC, Hypalon or PU) together with a supporting fabric; polyamid (Nylon) or polyester. All boat fabrics can be found with both types.

In the production of the final fabric the polymer is added to the supporting fabric either by extrusion or by a coated hot roller. When adding the polymer with a coated hot roller the tear strength of the fabrics is considerably higher than that of fabrics made by extrusion.

II: What is PVC fabric for inflatable boats

PVC: This is a plastic coating that is chemically known as polyvinyl chloride and is applied as a sandwich coating to polyester or nylon fabric. PVC is not a flexible material in its simple state and requires an additive to make it pliable and to be utilised as a coating to the base fabric.

Older PVC fabrics gained a reputation for the plasticising additive degrading over time due to exposure to ultra-violet light (UV), which made the PVC brittle and lead to cracking. Modern advances have significantly addressed this issue and quality PVC fabric manufacturers provide 10 year+ UV guarantees on their marine grade fabrics.

A PVC tube is the cheapest production material and can last for up to 15 years and is now used in most mass-production boats as the joints can be rapidly welded using thermal or high-frequency welding. They can also be glued, making repairs quick and simple.

III: What is Hypalon fabric for inflatable boats

Hypalon: This is a synthetic rubber coating onto polyester or nylon fabric and usually with a neoprene coating on the back of the fabric. The rubber coating is very hardwearing and can last for over 20 years if cared for by keeping your boat clean and applying a UV conditioner.

Hypalon joints are glued by butting the fabric together and applying glued cover strips or tapes over the seams, or the sections can be overlapped and glued. Hypalon fabric is considerably more expensive that PVC but is a similar cost to good quality PU fabric. Hypalon is manufactured in a wide range of colours and textures.

IV: What is PU (Polyurethane) fabric for inflatable boats

PU is the relatively ‘new kid’ on the fabric block. There is independent test evidence to support quality PU manufacturers’ claims that PU has superior airtightness than Hypalon fabrics, and also has high levels of wet and dry abrasion resistance combined with high-tensile strength. The fabric price is comparable to good quality Hypalon fabric but considerably more expensive than PVC fabrics. Good quality PU is designed to last for up to 15 years, but there are earlier examples that are still in use after 20 years+. PU fabric is currently manufactured in a limited range of colours, compared to the wide range of colours available with Hypalon and PVC fabrics.

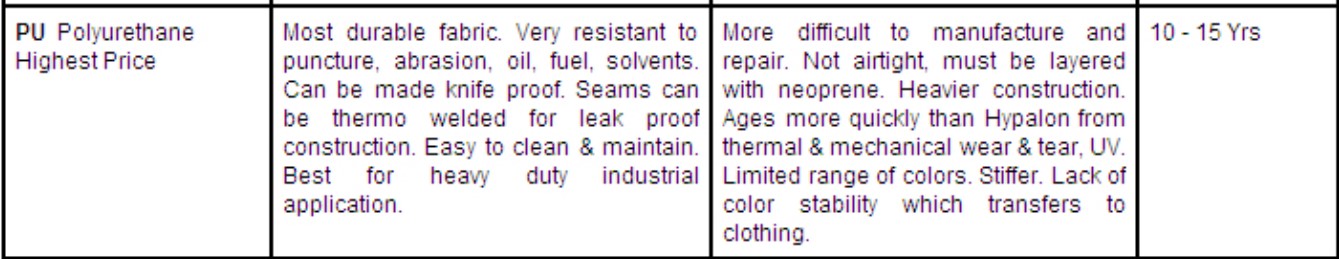

V: How to test Fiber based rigid inflatable boats fabric

There are a number of methods to identify what boat fabric you have:

1. Check-out the list of RIB and inflatable boat manufacturers below.

2. Look at the back of the tube fabric (i.e. the inside of the tube through the inflation valve or a tear in the

inflation collar or tube, if possible (see here for tips and advice on how to repair inflatable boat. Hypalon material is a dull dark grey or black colour on the back face of the fabric, whereas PVC and polyurethane (PU) is the same glossy colour on both sides of the fabric.

3. Abrade/sand the inflatable boat fabric in an inconspicuous area; Hypalon fabric will turn dull and produce a dust or residue, whereas PVC will scratch but maintain the same glossy colour.

4. Apply a small amount of solvent to an inconspicuous area of the tube fabric (This test only works if you use the correct solvent, i.e. which is known chemically as Methyl Ethyl Ketone also known as Butanone – this is available from If the fabric is PVC then the material will feel tacky and the solvent may leave some of the fabric colouring on the application cloth. Hypalon will leave an oxidized (dull) appearance and sometimes some colouring on the application cloth but Hypalon material will not feel tacky. These solvents are dangerous and should be used/applied with appropriate care in a well-ventilated area with no naked flames.

VII: Comparison among the different sport boats fabric

Derflex is one of the professional raft material manufacturer in China with experience over 20 years. we focus on manufacturing and exploring different raft materials.

Our inflatable fabric for sport boats advantages: Wear resistance, low temperature resistance -35 ℃, still tear resistance; Anti UV, Anti sharp puncture

VIII: About DERFLEX

Our team would love to chat further about these materials or any other raft related questions you have. Check out our contact info below for more details. Welcome to reach us at Ann Li (What”s APP&Wechat): +86-187-0192-0943 E-mail: ann@derflex.com