What''s the best pond lining fabric

What's the best pond lining fabric?

What's the pond lining fabric?

Pond liners are large, foldable sheets made of either plastic or synthetic rubber. Depending on the material, some companies can custom manufacture liners for individual ponds in-factory.

In other cases, you’ll have to hire professionals to form a complete pond liner material by joining multiple sheets in the field using methods like welding or taping.

A liner material’s pliability, weight, and thickness all influence how difficult it is to install and what you can do with it

Every pond liner’s primary job is to hold your pond’s water. However, manufacturers make flexible liners — often called “geomembranes” by engineers — with a wide variety of materials, each of which has pros and cons depending on a pond’s individual setup.

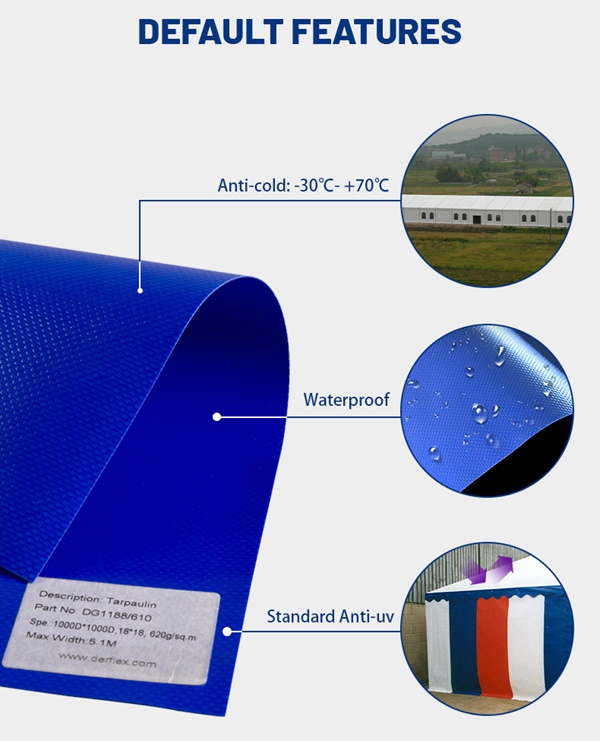

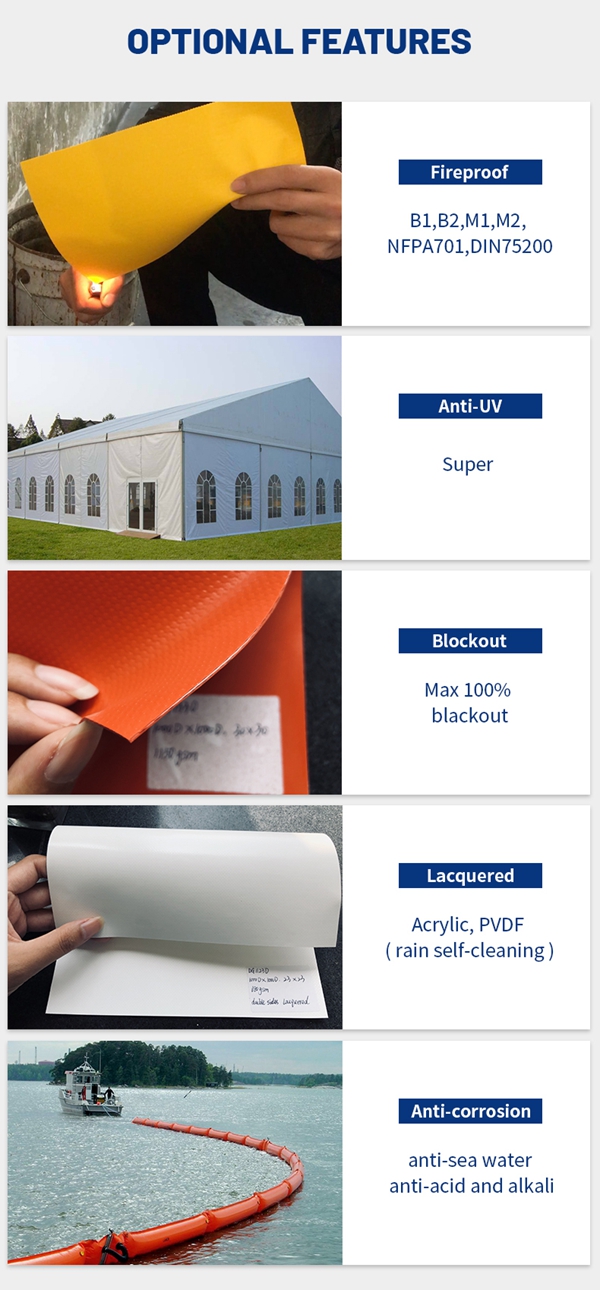

Your liner needs to stay stable in the hottest and coldest temperatures your area is likely to experience, and it shouldn’t snag, puncture, or tear due to objects or irregularities in the ground underneath. If your liner is exposed, it has to stand up to both UV rays and harsh weather.

Chemical resistance, flexibility, cost, and toxicity to fish can all vary as well.

Many geomembrane liners are designed for large lakes or landfills, and as a result they may not perform as well in smaller backyard ponds.

For these reasons, it pays to know a little about different liner materials before you invest in one.

Ⅱ,What’s the Purpose of a pond lining membrane?

The most important function of a pond liner is to keep water from leaking out of your pond. Unless you dig your pond in very clay-rich soil, water will slowly seep out of your pond and into the surrounding ground without a liner.In turn, you’d be forced to refill your pond every few days or even more frequently, which would be time consuming and cause a major disturbance for your fish and plants.Even if you do have a clay-rich soil, it is typically worth using a pond liner. Even clay will absorb water, so you’ll still experience a slow leak of water out of your pond.

Beyond sealing in water, pond liners also offer a few advantages for your pond’s plants. Pond liners can serve as substrates for plants to anchor onto, or as a base onto which you can layer additional substrate.

Ⅲ,Detailed pond liner material Comparison (Advantages & Disadvantages)

1) HDPE pond liner material (high density polyethylene)

High-density polyethylene (HDPE) liners, also known as reinforced polyethylene liners, are one of the best choices for flexible pond liners.

HDPE has very good UV resistance and functions well in cold temperatures.

It’s also strong and very stiff, meaning that it’s not prone to sudden length-wise tears. HDPE’s most desirable characteristic, though, might be its superior resistance to a wide range of chemicals.

HDPE liners are commonly used in landfills and chemical containment sites, but they are also safe and well-suited for fish ponds. No matter where they are, HDPE liners are very durable, having been found to last upwards of 36 years when covered.

HDPE membrane offer even better puncture resistance than either EPDM or PVC liner, while weighing roughly one-third as much and being half as thick. That makes them easy to ship, install, and conform to your pond no matter what shape you’re building.

In addition, HDPE sheets can be welded together with a heat gun, which makes for a more stable joining than liner tape.

Better yet, HDPE liners are strong enough that they typically don’t require you to build an underlay for your pond. You also won’t have to replace your liner once your pond is built – HDPE liners can last up to 40 years if taken care of.

But, the only real downside to HDPE liners is that the material is significantly more expensive than either EPDM or PVC pond liner. However, the extra cost is well worth it for experienced pond owners who are moving up from a preformed liner or who plan to keep their pond for decades to come.

HDPE Liners

Advantages:

Excellent chemical resistance

Good UV resistance

Relatively inexpensive

Weldable

Fish safe

Very durable

36+-year lifespan when covered

Performs well in cold temperatures

Disadvantages:

Poor flexibility

Susceptible to puncture

Heavy weight makes it more expensive to ship, difficult to install

No custom fabrication; must be welded on-location

Prone to scratches from rough surfaces

Poor resistance to stress cracking

May expand in very high temperatures

Packaging:

Pearl cotton film for waterproofing;

hard tube with 5 paper layers, to avoid damage during transportation;

Customized Logo printing for free;

Foam pad taken before loading the container;

Plastic covering on both side of the tube, more firm

Delivery time:

10,000SQM 25days production time, and even better for urgent orders.

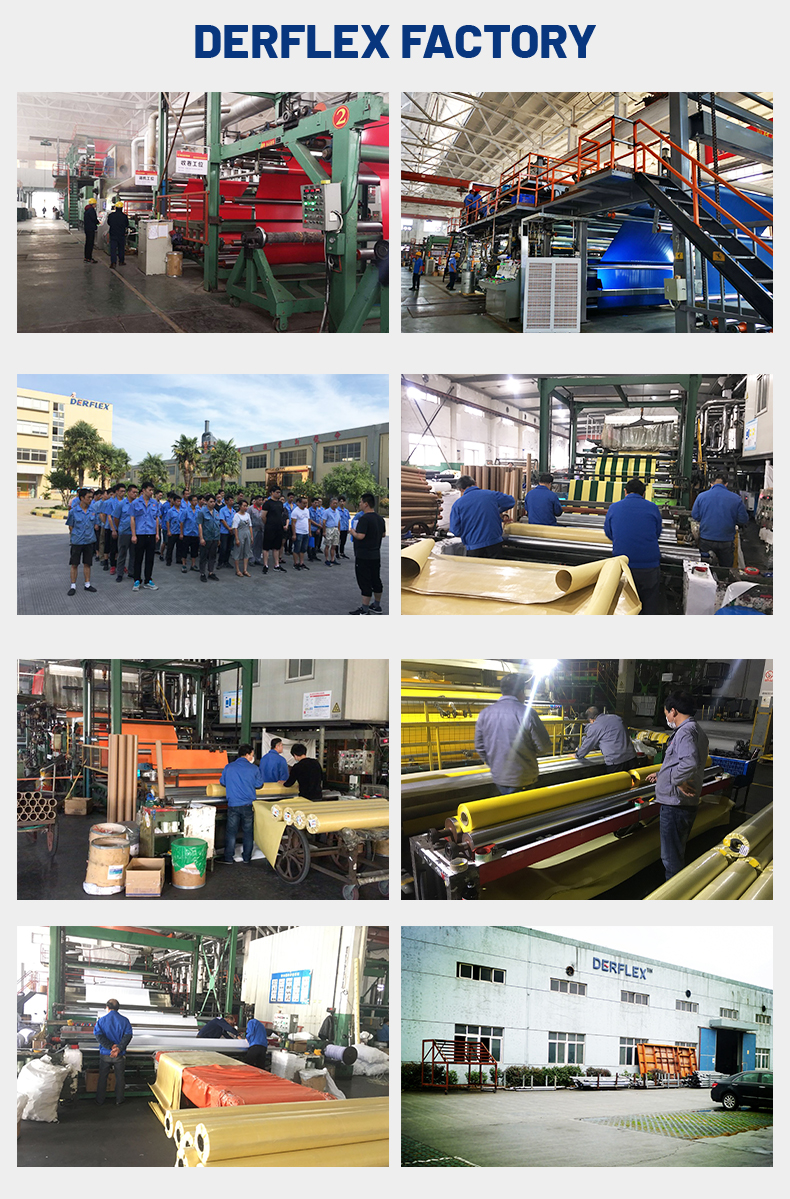

Ⅵ, About DERFLEX China:

1.Quality assurance: We will 100% return money if any quality problem, our QC department will inspect each order

before ship.

2.Experience: 20 years’ R&D and production experience.

3.Production area: 60,000 square meter, 20 senior engineers and 350 workers.

4.International exhibition: Every year we attend USA, Germany, Russia, Spain international exhibitions etc.

5.Product quality: Our enhanced products are products that combine European and American quality standards.

DERFLEX Production Lines

1. Knife coating production lines to make High adhesion coted fabrics, the high adhesion makes higher outdoor durance and Anti-UV characters

2. Hot-melt coating production line: With high water-resistant and water tight and air tight characters, which can make inflatable products

DERFLEX is exporting to more than 100 countries all over world.

Professional Sales and After-sale survice;

Experienced production team;

Good reputation on quality control;

Immediate response to customers' questions

Makes DERFLEX stronger business range on PVC coated fabrics industry, which can compete >95% products from other factories

Quality control

DERFLEX coated fabrics quality control process

During Production:

1. Online raw material quality control

2. Online surface flatness control

3. Online defects inspection

4. Online weight control

5. Fabric Structure

After production:

1. Roll Width

2. Roll Length

3. final product weight

4. tearing strength

5. breaking strength

6. adhesion

7. Aging test

8. Welding test

9. Abrasion test

10: Check fabric structure.

Contact :

Sales manager: Masha

Cell Phone:+86-131 6285 8753(What"s App&Wechat)

Email: masha@derflex.com