Types of TPO coated roofing membrane

Types of TPO coated roofing membrane

I: What is TPO coated roofing membrane

TPO waterproofing membrane is thermoplastic polyolefin waterproofing membrane, it is based on thermoplastic polyolefin (TPO) synthetic resin which combines ethylene propylene rubber and polypropylene with advanced polymerization technology, adding antioxidant and anti-aging agent. The new waterproof membrane made of softener can be made of polyester fiber mesh cloth as internal reinforcement material to make reinforced waterproof membrane. It is a synthetic polymer waterproof membrane waterproof product.

If you’ve seen a bright white roof, then you may be familiar with TPO roofing. As one of the most common roof types of big commercial facilities, TPO has some of the best energy savings for single-ply membrane roofing!

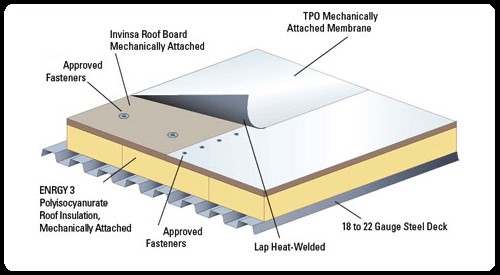

Single-Ply Membranes are sheets of rubber and other synthetics that can be ballasted, mechanically fastened, or chemically adhered to insulation creating a layer of protection on your commercial facility.

It is one of the most well-known types of commercial roofing material, there are several types to fit your budget and facility needs.

There are two main types of single-ply membrane commercial roofing: Thermoplastic Polyolefin (TPO) and Ethylene Propylene Diene Terpolymer (EPDM).

They differ in their chemical makeup, how they are installed, and their energy efficiencies.

II: TPO ROOFING Membrane working principle

II: TPO ROOFING Membrane working principle

Low-cost – TPO offers the same degree of protection as PVC roofs but at a fraction of the cost. This is particularly beneficial if you need to cover large amounts of roof area.

Reliable durability – TPO membranes resist mold growth, impacts, and punctures. It is made to be flexible to allow for a building’s thermal expansion and contraction which makes it ideal for buildings that need to house heat producing industrial equipment or refrigerated storage.

Simple installation – Single-ply roofing membranes can be manufactured in lightweight larger sheets that are easier to install with fewer seams, translating to less time required for installation.

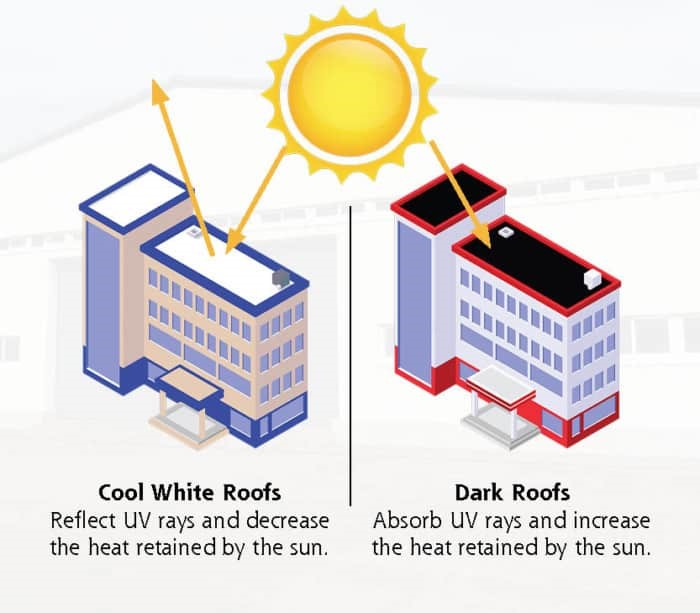

Exceptional energy-efficiency – TPO has a reflective white surface which exceeds the EPA’s Energy Star requirements. This is attractive to businesses and homeowners that are looking to reduce energy costs while keeping the building comfortable.

Environmental sustainability – Going green? TPO roofs are an ideal option. They reduce the amount of energy waste from your HVAC system through their solar reflective properties. It’s also a completely recyclable roofing option

IV: Type of TPO ROOFING Membrane

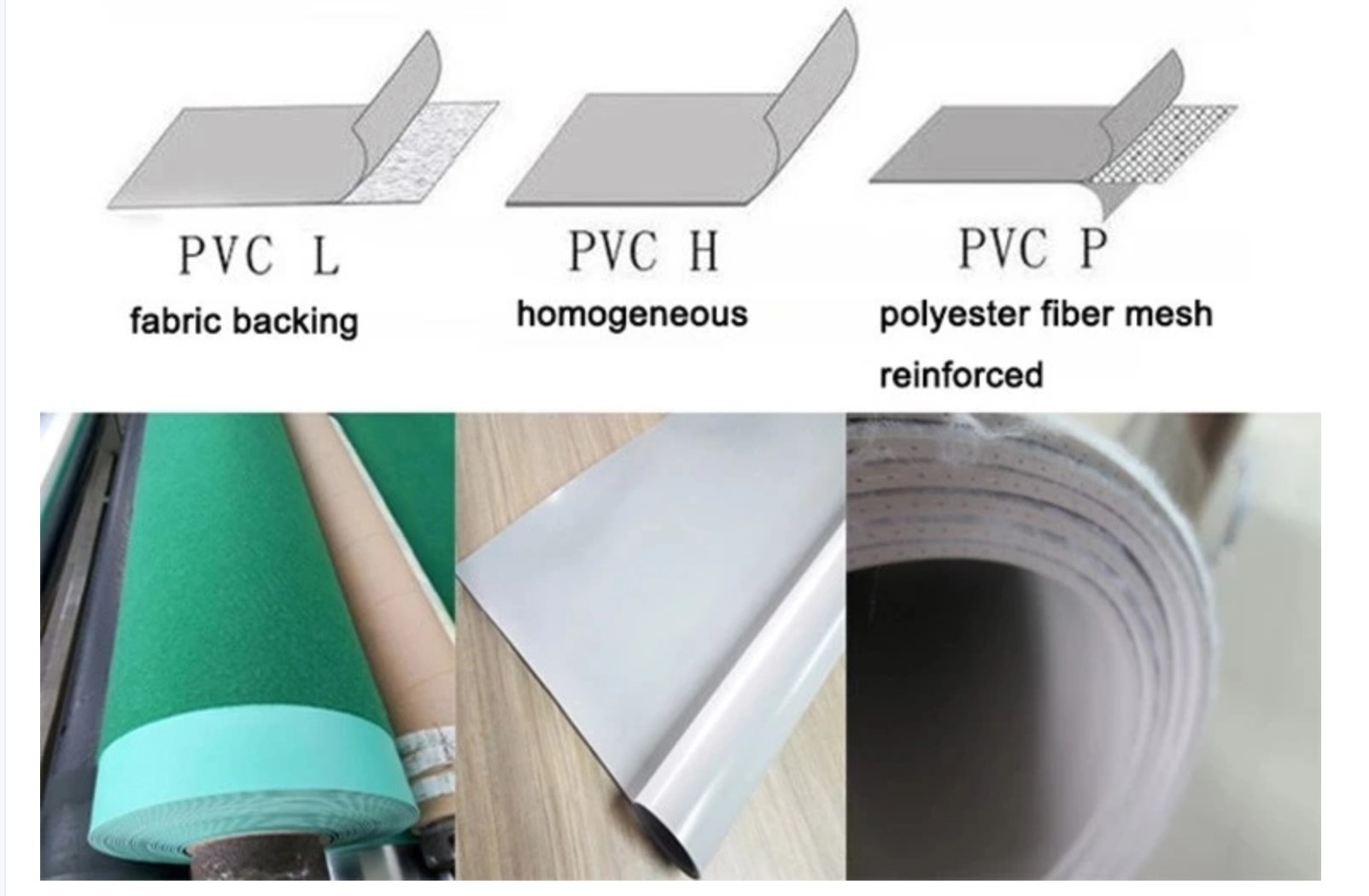

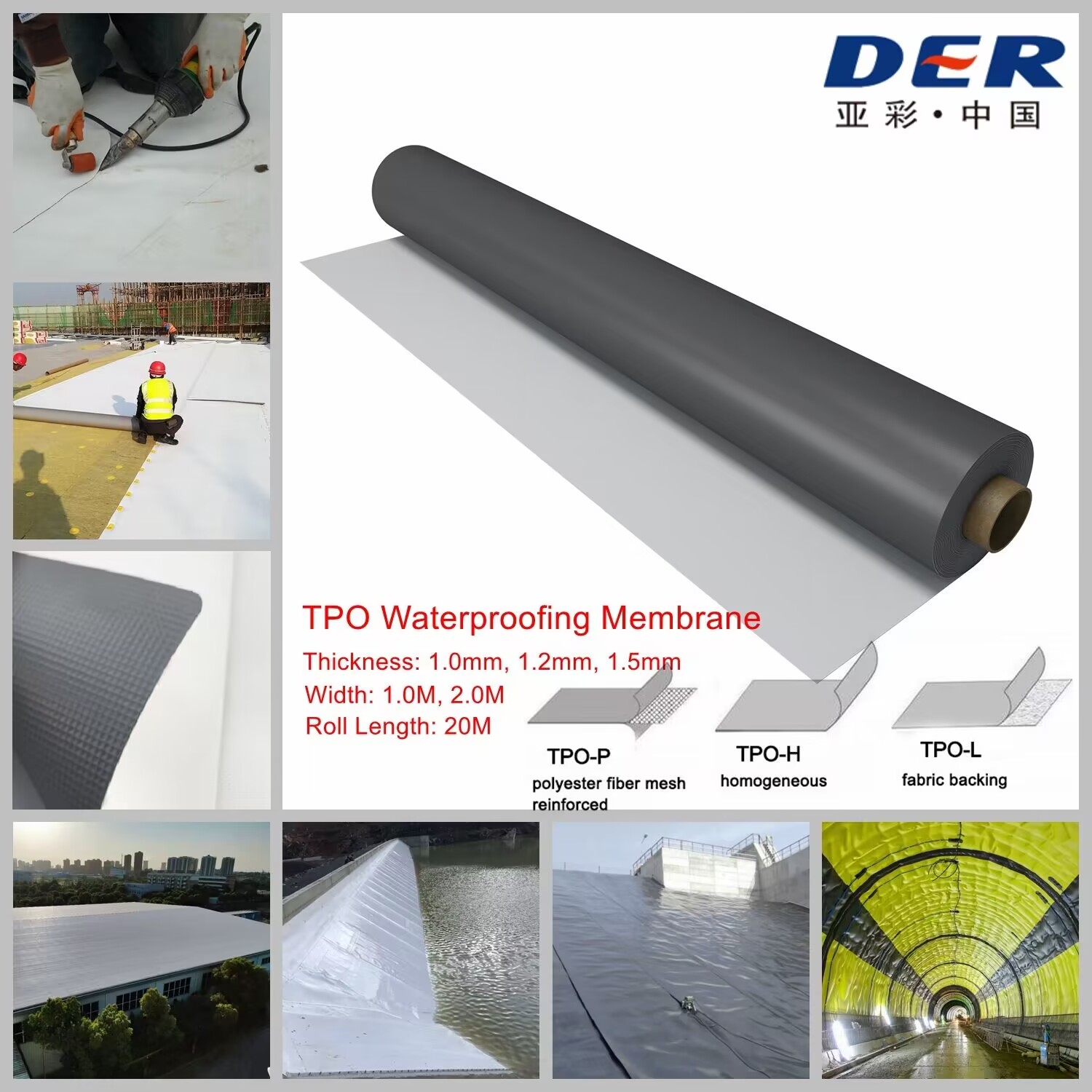

Type P: reinforced coil is suitable for mechanical fixed waterproof system.

Type L: fiber backing coils are suitable for concrete base bonding systems or mechanical fastening systems.

Type H: homogeneous coil is suitable for flooding and fine node processing.

V: TPO ROOFING Technology specifications

|

Thickness |

1.2mm, 1.5mm, 1.8mm, 2.0mm |

|

Width |

1m, 1.5m, 2.0m, 2.1m or customized |

|

Length |

20m, or customized |

|

Color |

White, grey or customized |

|

Type |

H, L, P |

|

OEM |

Available |

VI: How TPO Roofing Saves Money

The most common TPO material is bright white with highly reflective properties. This bright white roof installation can reflect UV rays and heat from the building, saving money during the summer months from decreased energy usage to cool the building interior.

VII: About Derflex

Derflex is one of the oldest TPO Roofing membrane manufacturer at China for more than 20 years.

We are majored in TPO roofing membrane production in recent years to meet the environmental protection requirement. Welcome to reach us at Ann Li (What"s APP :+86-187-0192-0943) E-mail: ann@derflex.com for more detail.