What's the difference between PVC roofing membrane and TPO membranes

What's the difference between PVC roofing membrane and TPO membranes?

I what is PVC roofing membrane?

PVC (polyvinyl chloride) is a single-ply white membrane used in both commercial and residential roofing. Due to the membrane being white, it reflects heat instead of absorbing it.

PVC is a great option If you have a flat roof over a living space because it’ll keep the room below cooler. It’s also a great option over a non-living space like a garage or covered patio.

Just know the white membrane will get dirty over time. So, you need to decide if seeing a dirty PVC membrane from a window is a big deal.

II What is TPO membrane?

TPO (Thermoplastic Polyolefin) is a roofing material introduced in the early 90s. It is a single-ply roofing membrane composed of 3 layers (a TPO polymer base, a polyester-reinforced scrim, and a TPO compounded top ply). According to a report by the National Roofing Contractors Association, it was developed as an alternative to rubber and PVC roofs and is one of the fastest-growing roofing systems on the market, making up an estimated 40% of the commercial market according to a report by the National Roofing Contractors Association. For many reasons, TPO roofing is one of the most highly recommended products on the market for commercial business owners.

III pros and cons for TPO

While PVC offers better resistance to puncture and weathering, TPO (like PVC) is recyclable and environmentally friendly. Its reflective surface reduces UV radiation and helps with energy efficiency.However, TPO is also less resistant to chemicals than PVC, so it is not the optimal choice where grease or harsh chemicals are involved. It may also be more difficult to install due to its stiffness. Additionally, as the popularity of the material is relatively new, some manufacturers may use subpar formulations that demonstrate a higher risk of membrane cracking.

IV Pros and cons for PVC

PVC has been a mainstay in construction for over 30 years, and its reputation for durability is well-deserved. PVC is highly resistant to chemical damage and somewhat resistant to punctures or weathering. It also tends to be more flexible and easier to install due to the addition of plasticizers in its formulation.

V Considerations When Choosing TPO or PVC Roofing

The similarities between PVC and TPO make either material a likely option for most flat roofing projects. When deciding between the two materials, there are a few considerations that can help determine which is best suited for the project, such as:

1 Cost

TPO is cheaper than PVC per square foot of material. However, the amount of labor during installation is about equal for both materials, if not slightly more intensive for TPO.

2 Labor

PVC can be easier to install due to its greater flexibility. Additionally, some TPO installations may require more work if the contractor decides to use glued seams over welded seams.

3 Industry standards

Due to the relatively regular updates to ASTM standards for TPO, some manufacturers may not follow the most recent standards. The same risk is much lower for established materials, such as PVC. When using TPO in roofing systems, it’s essential to pick a reputable supplier.

4 Membrane quality

Regardless of whether the roofing project uses TPO or PVC, it’s important to vet and choose an experienced Some of the things to look for in a supplier are extensive industry experience, consistently high-quality and industry-compliant products, and a clear warranty policy.

5 Energy efficiency

TPO and PVC roofing membranes both provide naturally reflective surfaces that reduce UV radiation penetration and facilitate greater energy efficiency. By using smoother TPO and PVC membranes, the roofing system is also better protected from dirt and debris buildup, which can reduce the membrane’s reflective properties. All major manufacturers of TPO and PVC membranes comply to the most stringent of energy codes, including in Chicago.

6 Durability/Longevity

In theory, TPO roofs should be more durable because they lack plasticizers. However, many PVC roofs have withstood decades of wear without failure, so it’s less of a concern than some make it out to be.

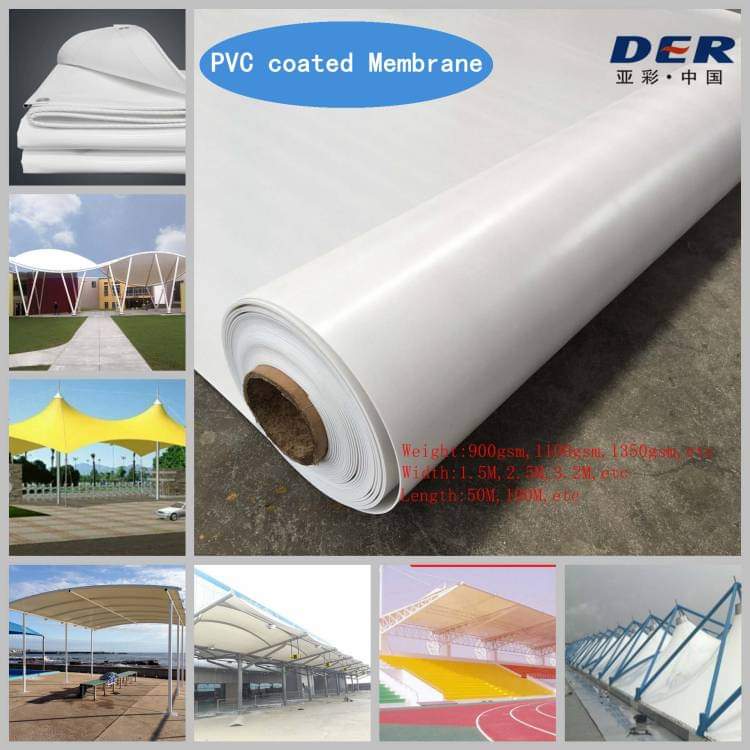

VI Introduction for DERFLEX

DERFLEX is a professional manufacturer of . We have our own factory, which is located in Zhejiang province, China , with 7 production lines, the supply capacity is 300,000sqm/month. We can produce different kinds of wide format digital printing media. Such as coated Frontlit, backlit, laminated PVC tarpaulin, blockout,mesh,self-adhesive vinyl, one-way vision, perforate vinyl, wide format print cotton canvas, PVC coated tarpaulin, photo paper, reflective material, projection screen fabric.

Our main product is PVC tarpaulin and it is widely used as truck/trailer/container cover, tents, pallet cover,strip garden fence,

awnings, inflatable products, adumbral materials for building facility and house.

For further business communication, welcome to contact:

Tel: +8617316447897(whatsapp&wechat)

Email: ellaine@derflex.com

Web: www.derflex.com