PVC Leather

Soft Cover Leather refers to a wall decoration method that is packaged with flexible materials on the surface of inner application. PVC leather material are soft in texture and soft in color, which can soften the overall space atmosphere, and its deep three-dimensional sense can also enhance the quality of the home. In addition to the function of beautifying the space, it is more important that it has the functions of sound absorption, sound insulation, moisture resistance and anti-collision.

PVC artificial leather is a leather-like plastic product made of PVC resin, additives and fabric base through different processing techniques.

Additives: stabilizers, plasticizers, lubricants and fillers, etc.

Substrate: generally, textile fabric and knitted fabric

Process: Calendaring, the kneaded mixture is made into the required film or sheet on a calendar, and it is laminated with the preheated fabric base (using adhesive), and then embossed, cooled, and surface treated to make artificial leather. The calendaring production line of PVC leather fabric is relatively mature and complete, and it has all been made in China. It has the advantages of high automation control level, high product size accuracy and high production efficiency.

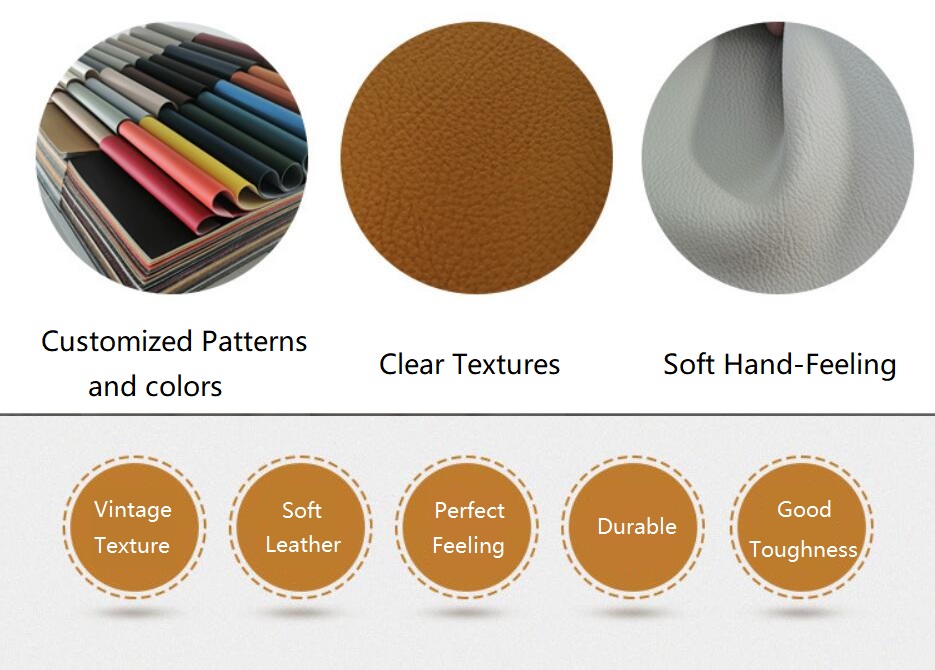

There are many colors and patterns of flame-retardant PVC leather.

Natural color, gorgeous color, rich and diverse, beautiful pattern, elegant and high-end style, simple and generous, soft color, warm and rich, square corners and continuous symmetry are all the effects that can be described as PVC leather decoration. Flower patterns such as flowers, abstractions, squares, and rhombuses are widely used in soft bags. Steady black, romantic purple, passionate red, tranquil blue, sweet pink, rustic gray, and elegant light green are widely used in soft bags.

Advantages of PVC leatherette fabric

Environmentally friendly, flame-retardant, abrasion-resistant for more than 100,000 times. Soft leather wraps a hard wall, which will give people a warm and peaceful feeling. The wall decorated by the soft package is simple and generous, the color is soft, warm and rich, the edges and corners are square, the continuous symmetry, and the feel is relatively soft and comfortable.

There are three important reasons why PVC can be widely used in the building materials industry:

1. PVC unique performance (rainproof, fireproof, antistatic, easy to form),

2. The affordable price of PVC. Ordinary adhesive film is directly attached to the surface of the board with glue at room temperature, so after one or two years, the film is easy to fall off. The PVC film is pressed on the surface of the board at a high temperature of 110 degrees using a dedicated vacuum laminator, so it is not easy to fall off. Although PVC embossed leather has excellent quality assurance, some people may say that PVC imitation leather is a chemical product after all, it is not comparable to natural materials, toxicity and odor cannot be ruled out, and it will inevitably cause harm to the environment. The fact is not the case. This is because the raw materials for the production of PVC film are specially refined, and the toxic substances are completely extracted. Therefore, PVC is completely non-toxic and tasteless, and does not have any irritation to the human skin or respiratory system. For people who are allergic to paint, furniture or kitchen utensils wrapped in PVC film are very suitable.

3. Easy to clean. Take the furniture with PVC leather as the surface material as an example. If this furniture does not use PVC leather, but use ordinary wood as the surface, then only cleaning and repairing will increase an astonishing cost. In a small town in the United Kingdom, people have used wooden windows for the past two decades. Someone investigated the cleaning and maintenance costs of these windows and compared them with the cleaning costs of PVC leather material.

1. Environmental protection PVC leather (lead, PAH, heavy metals, PH value, o-benzene, organotin compounds, APEO, DMF can pass the EU and U.S. environmental testing)

2. Glove leather(wear-resistant, anti-slip, anti-static)

3. Cold-resistant leather (has good resistance to low temperature and tortuosity, and can withstand more than 3000 times at minus 25℃)

4. Flame retardant antibacterial leather(flame retardant effect can reach: continuous burning ≤ 5 seconds, flame retardant ≤ 5 seconds, flame retardant length ≤ 8 seconds)

5. Waterproof and moisture-permeable PVC (water pressure resistance: FZ/TO1004-1991: 3000-100OMMH20 water column; moisture permeability: BW testability: 3000-7000g/m/24 hours)

6. Wear-resistant and corrosion-resistant waterproof fabric(special waterproof fabric with wear-resistant, acid-resistant, alkali-resistant, corrosion-resistant, hydrolysis-resistant, and cold-resistant)

7. Credential leather (has a certain degree of scratch resistance, wear resistance, ink printing resistance, high temperature resistance)

Some popular patterns of PVC leatherette

Lychee pattern

|

Product name |

Lychee pattern PVC leather fabric |

|

Raw Material |

PVC |

|

Thickness |

0.5mm/20mil |

|

Colors |

33 colors for customer choice |

|

Base fabric |

Knitted Fabric |

|

Width of the roll |

137cm or 54’’ |

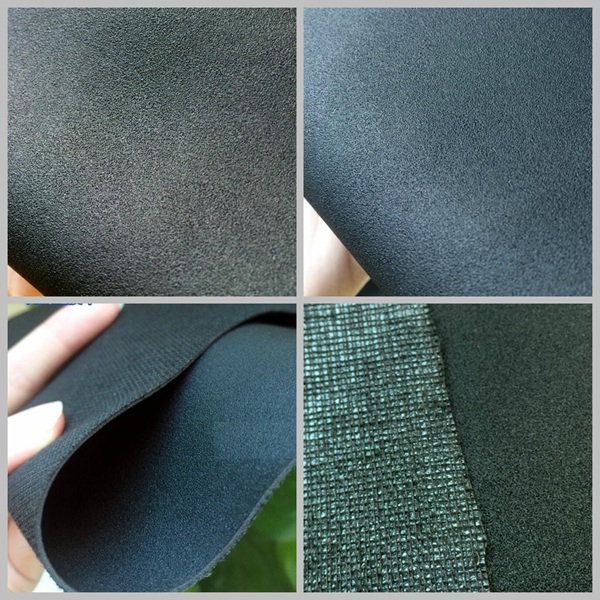

Coarse matte texture

|

Product Name |

Coarse matte texture PVC leather |

|

Thickness |

1.0mm |

|

Width |

1.37M |

|

Color |

Black |

|

Base Fabric |

Polyester Fabric |

Cow neck pattern

|

Product Name |

Cow neck pattern PVC fabric leather |

|

Thickness |

0.8mm |

|

Width |

137cm |

|

Color |

Black |

|

Base Fabric |

Black Knitted Fabric |

Crocodile

|

Product Name |

High-gloss crocodile leather |

|

Raw Material |

PVC |

|

Thickness |

0.5mm |

|

Color |

Black |

|

Base Fabric |

137cm (54”) |

Straw mat pattern

|

Product Name |

Straw mat pattern PVC leather |

|

Material |

PVC |

|

Thickness |

0.7mm |

|

Color |

Black |

|

Base Fabric |

Knitted Fabric |

|

Width |

137cm |

Anti-slip leather

|

Product Name |

Anti-slip leather |

|

Material |

PVC |

|

Thickness |

0.8mm |

|

Color |

Black |

|

Base Fabric |

Knitted Fabric/Oxford Fabric |

|

Width |

137cm |

PVC leather fabricscan be customized for different applications. Please feel free to drop a call if you need

Applications

The application fields of PVC leatherette fabric involve all aspects of people's lives, such as shoes, clothing, furniture, luggage and car interiors. Among them, clothing and furniture account for the largest proportion. The annual demand is rising year by year, and the proportion is also increasing.

With the rapid development of the domestic automotive industry in recent years, the domestic automotive interior market has a relatively rapid demand for PVC leather cloth. Especially in 2009, automotive decorative leather reached 180 million meters, an increase of 44% over 2008. As the automobile industry is a pillar industry, the future automobile development trend is good, and the demand for corresponding interior materials will also maintain growth.

Soft packagingis mostly used in high-end hotels, clubs, KTVs and other places, and are rarely seen in homes. Commercial houses, villas and townhouses in some high-end communities will also be used on a large-scale during renovation. It is also widely used in the decoration of high-end hotels, villas, KTV, sliding doors, background walls, sofas, car interiors, etc.

Main Applications

PVC packaging leatherused for luxury packaging of Gift wrap, Jewelry packaging, etc

PVC stationery leatherfor Stationery storage

PVC luggage leather/ PVC handbag leather for making handbags and luggage bags

PVC car leather for Automotive interior

PVC Furniture leather / PVC Sofa Leather

Why DERFLEX?

1. 20 years’ experience focusing on PVC leather fabrics.

2. Non-stopping cooperating with University Labs to develop new materials to meet customer requirement;

3. Sources of relative materials to make correct products

4. After-sale service: Any quality issues can be solved within 1 week