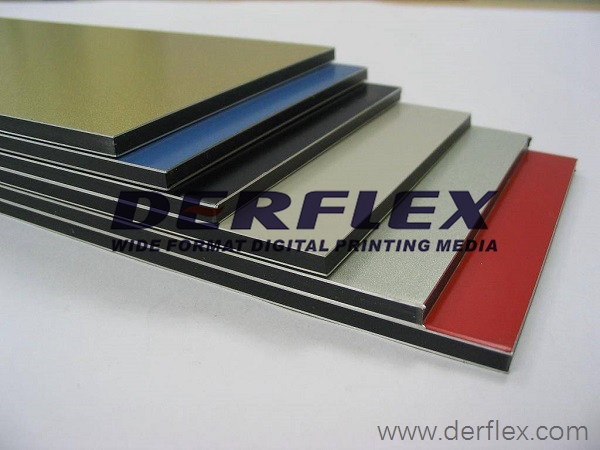

Aluminum Composite Panels

The unique properties of the aluminum-plastic composite panel determine its wide range of uses: It can be used for building exterior walls, curtain wall panels, renovation and refurbishment of old buildings, indoor wall and ceiling decoration, advertising signs, display racks, purification and dust prevention. engineering. It is a new type of building decoration material

Applications of Aluminum Composite Panels

1, the building exterior, curtain wall panels.

2. Modification and refurbishment of the old building's external walls.

3, balcony, equipment unit, indoor compartment.

4, panels, signage, display stand.

5, interior wall decoration panels, ceilings, advertising signs.

6, industrial timber, cold-car body.

7, air conditioners, televisions and other appliances shells.

Aluminum Composite Materials performance

Super stripping degree

The aluminum-plastic composite panel adopts a new process and improves the peeling strength of the key technical indicator of the aluminum-plastic composite panel to an excellent state, which improves the flatness and weatherability performance of the aluminum-plastic composite panel.

Material is easy to process

The weight of aluminum-plastic composite board is only about 3.5-5.5 kg per square meter, so it can reduce the damage caused by the earthquake disaster and it is easy to handle. Its superior construction properties can be achieved by simple woodworking tools for cutting, cutting and planning. Edge, curved into a variety of shapes, right angles, with the designer, to make a variety of changes, easy installation and quick reduction of construction costs.

Excellent fire performance

In the middle of the aluminum-plastic panel is a flame-retardant material PE plastic core material, on both sides is extremely difficult to burn the aluminum layer. Therefore, it is a safety fireproof material that meets the fire resistance requirements of building regulations.

Impact resistance

High impact resistance, high toughness, no damage to the top coat, strong impact resistance, and no damage due to wind and sand in areas with large wind and sand.

Super weather resistance

Thanks to its unique advantages in the use of KYNAR-500 based PVDF fluorocarbon paints and weatherability, it can be used for up to 20 years without damaging the beautiful appearance in hot sun or cold snow. fade.

Uniform coating

After chemical conversion treatment and application of Henkel's film technology, the adhesion between paint and aluminum-plastic panel is uniform and the colors are diverse, allowing you to choose a larger space and show your individuality.

Easy maintenance

Aluminum-plastic panels have significantly improved their resistance to contamination. China's urban pollution is more serious. After a few years of use, it needs to be maintained and cleaned. Because of its good self-cleaning properties, it is only necessary to use a neutral detergent and clean water. After cleaning, the plates will become permanently new.

Easy processing

Aluminum plastic board is a good material for easy processing and molding. It is an excellent product for pursuing efficiency and winning time. It can shorten the construction period and reduce costs. Aluminum-plastic panels can be cut, cut, grooved, band sawed, drilled, machined and countersunk, cold-formed, cold-folded, cold-rolled, riveted, screwed, or glued.

1, good weather resistance, high strength, easy maintenance.

2. The construction is convenient and the construction period is short.

3, excellent processing, heat insulation, sound insulation and excellent fire performance.

4, good plasticity, impact resistance, can reduce the load on the building, good shock resistance.

5, smooth, light and strong.

6, to choose more colors.

7, processing equipment is simple, on-site processing.

8, flowers and patterns can be customized production

Excellent fire performance

In the middle of the aluminum-plastic panel is a flame-retardant material PE plastic core material, on both sides is extremely difficult to burn the aluminum layer. Therefore, it is a safety fireproof material that meets the fire resistance requirements of building regulations.

Impact resistance

High impact resistance, high toughness, no damage to the top coat, strong impact resistance, and no damage due to wind and sand in areas with large wind and sand.

Super weather resistance

Thanks to its unique advantages in the use of KYNAR-500 based PVDF fluorocarbon paints and weatherability, it can be used for up to 20 years without damaging the beautiful appearance in hot sun or cold snow. fade.

Uniform coating

After chemical conversion treatment and application of Henkel's film technology, the adhesion between paint and aluminum-plastic panel is uniform and the colors are diverse, allowing you to choose a larger space and show your individuality.