What is the longest lasting tarp material

What is the longest lasting tarp material?

I) What is Tarp material?

Tarp is a heavy, waterproof sheet of material, an industrial fabric used for outdoor coverings and tents.

II) 5 Types of Tarp material

1. PE tarp

PE waterproof cloth is a kind of lightweight plastic waterproof cloth, with characteristics like excellent wear resistance, tear-resistance, and anti-stain.

2. PVC tarpaulin laminated

PVC Tarpaulin sheets are one of the most important materials used for creating temporary or makeshift shaded areas for waterproofing.

3. PVC tarpaulin coated

Generally speaking, a coated tarp has a stronger peeling resistence than a laminated tarp. If you have special needs, it is recommended that you use a coated tarp.

4. Canvas tarpaulin

Not only can cotton tarpaulins effectively provide excellent protection against sun protection, dust and other harsh environmental influences, but the breathable fabric can also protect your items from rust, mold, and heat damage.

5. PVC tarpaulin with PVDF coated

With outdoor durance more than 10 years, normally used as Architecture membrane, is said to be most lasting tarp material.

III). How to choose the right Tarp

We have to choose suitable products according to actual needs, here are some suggestions for you:

1. Covers for short-term use, PVC laminated, lightweight tarpaulins can be used;

2. For short-term, if you don’t want to recycle, you can use PE tarpaulin, which is self-degradable;

3. Temporary tents, emergency tents, can use PVC coated fabric 610gsm;

4. Stadium ceilings, parking sheds, etc., which need to be used for a long time, use PVC membrane materials.

IV) Whats the longest lasting tarp material:

PVDF membrane is a kind of high-strength flexible material. It is a substrate that is woven with fibers and then reinforced with resin as a coating on both sides of the substrate. The fabric in the center of the film is divided into two types: polyester fiber and fiberglass, and the resin used as the coating is polyvinyl chloride (PVC) resin.

V) In terms of physical and mechanical properties, DERFLEX PVDF architectural textile substrate and coating have the following characteristics:

1. Substrate: tensile strength, tear resistance, heat resistance, durability, fire resistance, etc.

2. Coating: weather resistance, stain resistance, processability, impermeability, light transmittance, etc.

PVDF membrane is no longer rare in the construction market, and its selection of membrane material colors is very rich. Compared with ordinary PVC membranes, PVDF membrane has improved durability of about 10-15 years, that is why PVDF is considered the most durable membrane.

VI) Features of DERFLEX PVDF membrane:

1. Long service life: Compared with the 3-year service life of normal tarps, the acrylic tarps can reach more than 5 years, and PVDF tarps can have an outdoor service life of 10-15 years;

2. Self-cleaning: Thanks to the high adhesion strength between the PVDF self-cleaning coating and the PVC base, the welding reliability of the finished film, and adding a PRIMER coating layer between the PVDF self-cleaning coating and the PVC base. It not only solves the poor self-cleaning problems of PVC film, the plastic agent easily moves to the surface of the material and adheres to the air, and the rain dirt is not easy to clean, but also greatly improves the durability;

3. Optical performance: the membrane can filter out most ultraviolet rays and prevent the internal elements from fading. Its natural light transmittance can reach 25%. The transmitted light produces uniform diffuse light within the structure, without shadows, or glare. Under the combined action of ambient light and indoor lighting at night, the surface can emit a natural and soft glow, which is intoxicating;

4. Fireproof: At present, the widely used membrane can meet the demand for fire protection, have excellent resistance to high temperature and flame retardants, and meet the standards of France, Germany, United States, Japan, and other countries. ;

5. Good heat insulation: single-layer membrane heat insulation performance is the same as a brick wall, better than glass. Like buildings made of other materials, the internal temperature of membrane buildings can also be adjusted in other ways. For example: add a layer of insulation inside, use air conditioning heating equipment, etc.;

6. High strength: PVDF is a translucent polymer with 59% fluorine content. It has high impact resistance, abrasion resistance, creep resistance, and good toughness. It is the strongest among the fluoroplastics.

VII) DERFLEX PVDF membrane applications:

The structural membrane awning that has a wide range of applications, is composed of high resistance film (PVC or Teflon) and reinforcing elements (steel structure, steel column, or steel cable). With global warming, the summer temperature is higher. Shading facilities are especially important. In recent years, awnings with extensible membrane structures have appeared more and more in all corners of the city, such as shades for parking lots, sports tents, outdoor tents for buildings, leisure awnings in gardens and swimming pools, etc.

1. Shades for parking

It is suitable for cars, bicycles or electric vehicles, bus parking lots, etc., with novel styles, beautiful appearance, inexpensive and applicable. Garage design technology is becoming increasingly advanced. The material has the characteristics of reliable connection and convenient construction. The key is that the membrane has sufficient strength and excellent mechanical properties, as well as anti-aging, heat, and corrosion-resistant properties to ensure that the vehicle is not attacked by the scorching sun in the hot summer.

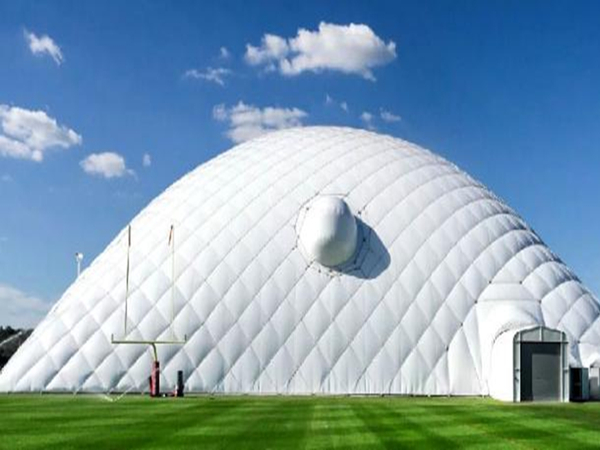

2. Sports tents

The membrane is suitable for school playground supports, gymnasium supports, and other places. The structural membranes are lightweight, large space, safe and fast construction, and long service life. Compared with traditional concrete supports, they have outstanding advantages.

3. Exterior tents of the building

Most of the cases where structural membranes are used for large building shading are building roof shading, that is, roofs that use membrane materials as covering materials. They can be divided into two categories:

inflatable structural membranes and extensible structural membranes. Inflatable structural membranes rely on continuous inner inflation to generate a certain pressure difference between the inside and outside. It makes the roof membrane subject to a certain upward buoyancy, in order to realize a large space. The extensible structural membrane is supported by steel columns or cables to achieve a beautiful and flexible exterior shape.

4. Leisure awning

The structural membrane of the leisure canopy is used in parks, communities, outdoor cafes or teahouses, private patios, and other places. The design of the structural membrane awning is simple and modern, and the shape is varied. Commonly used membrane materials for the umbrella are PVC and PTFE. Both materials are fire-resistant, high strength and durable, long-lasting, and unaffected by UV rays.

5. Awnings or umbrellas for swimming pools

The construction of awnings or umbrellas for outdoor pools is essential. The canopy is not only beautifully shaped, but more importantly, it has an anti-ultraviolet function and temperature insulation effect, which makes people more comfortable while playing in the pool.

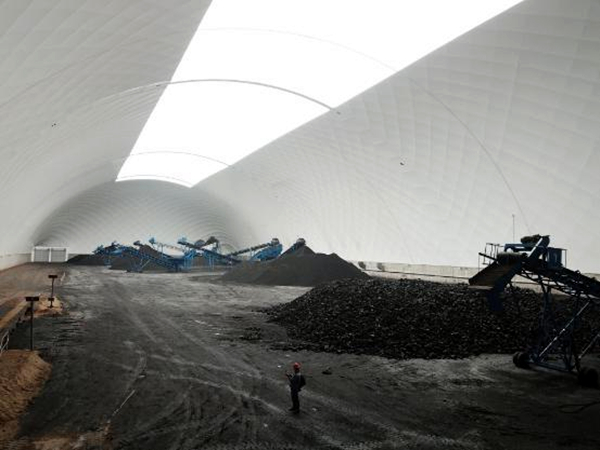

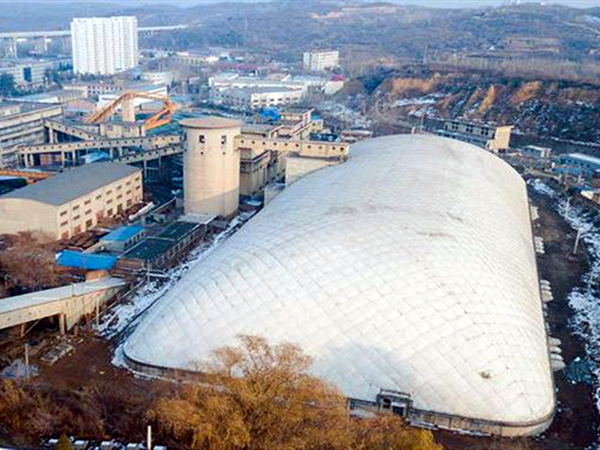

6. Inflatable charcoal shed

Anti-corrosion and weather-resistant PVDF film used in the large-scale inflatable coal shed As the situation of air pollution and smog becomes more and more serious, during the operation and storage yards of thermal power plants, Ports and docks, coal mines, metallurgy, coking, and other companies will generate dust when they encounter strong winds.

So they will not only cause a large number of materials, at the same time, they will also produce a large amount of pollution, which has a great impact on the surrounding environment. Nowadays, many business owners have chosen to use film to transform the patio. The outdoor coal yard was transformed into a fully enclosed structural film coal plant, which prevented the flight of coal dust, reduced the natural loss and heat loss from coal piles, reduced the loss of coal for enterprises, and improved resource utilization while meeting environmental protection requirements.

Structural Film Fully Enclosed Coal Plant is a kind of system that uses a special architectural membrane as the outer layer and is equipped with a set of smart electromechanical equipment to provide positive air pressure to the

interior to support the main body of the building.

The membrane is completely enclosed within the plant with dust suppression and dust-prevention treatment so that the carbon dust meets the environmental protection requirements. It is the preferred choice for thermal power plants, coal chemical plants, and coal projects so that the inspection and acceptance of environmental protection can be easily passed at the same time, and the closed storage and transportation mode is adopted throughout the process. Scope of application of fully film-enclosed coal tank: closed coal plant, large-scale coal plant, thermal power plants, coal power plants, etc.

VIII) About DERFLEX

Shanghai DER New Material Co., Ltd is the leading company of tarpaulin and advertising materials in China with more than 20 years of experience and owns a production area of 60,000 square meters.

It is assorted equipments of professional high quality PVC digital printing materials production lines, 3 calendars, 3 coating machines and 5 laminating machines, 25 senior engineers and 450 workers make our factory more competitive.

At DERFLEX we offer an after-sales service 24 hours a day.

Pls feel free to contact me, and I will reply to you within 30 minutes in working time.

Email: sopita@derflex.com

WhatsApp: 0086 137 6134 0239