Whats the difference between hot-melt PVC tapaulin and PVC knife-coated tarpaulin

Whats the difference between hot-melt PVC tapaulin and PVC knife-coated tarpaulin

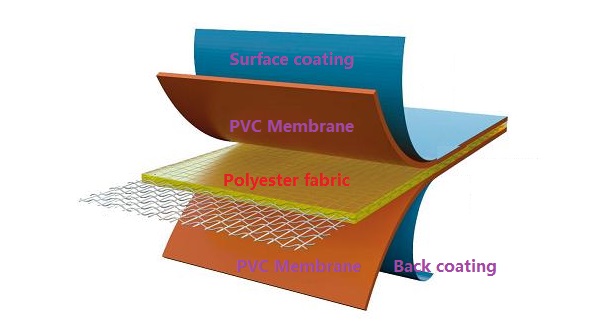

I: PVC tarpaulin is made up of high tensile polyester, high quality resin powder, plasticizer, stabilizer, proper amount of calcium powder, and tiny quantity of chemicals.

hot melt PVC Tarpaulin and PVC knife-coated tarpaulin are be same on the material structure.

They are both pvc membrane coated to the polyester fabric and are also both with surface and back coating as above pictures displayed.

II: What is hot melt pvc tarpaulin

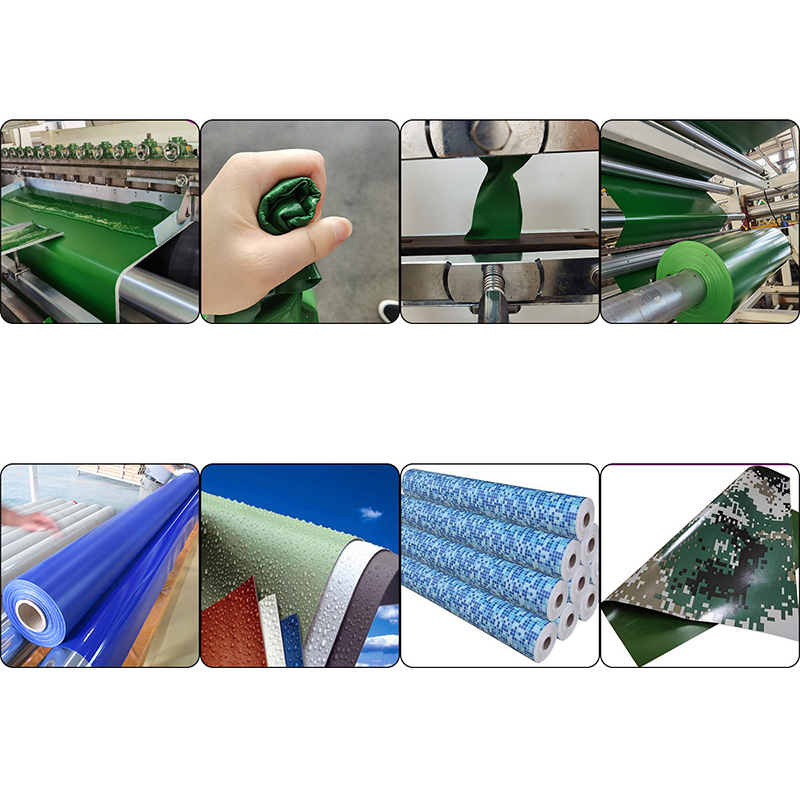

a. Hot melt pvc tarpaulin: is a polyester fabric laminated with PVC film both sides. Before lamination, the fabrics is passed through the glue, to make the heavy-duty PVC tarpaulin better adhesion.

This method is used for thermoplastic polymers such as polyurethane, polyolefins and PVC, which are applied by feeding granules of the material into the nip between moving heated rollers. There are two general designs in use, the Zimmer machine, which has two melt rollers the Bema machine, which has three. They are smaller version of calenders but differ in that they need a fabric (or paper or a film) as a substrate on which to deposit the film as it is produced. This method can apply resin (in the form of films) to fabric at a faster rate than that can be achieved by transfer coating or direct coating. This process is used to produce light weight coverings or tarpaulins.

b: what is the knife coated pvc tarpaulin

pvc knife coated tarpaulin is the prcess that the PVC raw material is 100% melted into liquid, the woven polyester fabric go through the PVC liquid and then go through the gap between 2 blade, to remove the extra PVC raw material.

Knife Coating is a process in which a polymeric layer is applied directly to one or both surfaces of the fabric. The polymer coating must adhere to the textile and a blade or similar aperture controls the thickness of the viscous polymer. The coated fabric is heated and the polymer is cured (that is, polymerized). Where a thick coating is required this may be built up by applying successive coating layers, layer on layer,Interlayer adhesion must therefore be high. Finally, a thin top layer may be applied for aesthetic or technical enhancement of the coating. Depending upon the end-use requirements, heavy-duty technical textile coatings may be applied at high weight, while other end-uses for high- technology apparel may require coating weights very low. The chemical formulation of the coating, the coating thickness and weight, the number of layers, the form of the technical textile and the nature of any pre-treatment (such as to stabilize the fabric dimensions prior to coating) are of great importance. Traditionally, coating has been applied to woven technical textiles, but increasingly warp-knitted, raschel, weft-knitted and nonwoven fabrics must be coated on the same line. The machinery and method of application of the coating formulation must be versatile, minimize tensions on the fabric that may lead to distortion or stretch, and eliminate problems in knitted fabrics such as curling selvedges. Scroll opening equipment, weft straightening, tension bars and selvedge uncurlers may thus be fitted. The lighter the weight of the technical textile the more prone will be the base fabric for coating to weft line distortion and selvedge curling.

c: the difference between the hot melt and knife coated pvc tarpaulin

III: Hot melt and knife coated pvc tarpaulin different applications:

a: hot melt pvc tarpaulin are widely used for outdoor covers, tent, container bag, ventilation tube etc.

b: knife coated pvc tarpaulin are mainly used for flexible water tank, inflatable castles and boats etc.

IV: Features: hot melt and knife coated pvc tarpaulin are both with excellent following features:

They have nature functions: waterproof, mould proof, wear-resistant, durable, cold resistance, aging resistance, etc.

a. Water-proof;

b. Mould proof;;

c: wear resistant;

d. Good peeling strength for welding.

e. cold-resistance and Anti-fire;

f: aging resistance;

g:Actylic treatment(optional)

V: About us-Derflex

DERFLEX is one of the oldest professional PVC tarpaulin manufacturer in China for more than 20 years. We have strict quality system and we focus on manufacturing and exploring PVC coated fabrics.

For more information, welcome to reach us at Ann Li( What”s APP&Wechat:+86-187-0192-0943 E-mail: ann@derflex.com