What is Drop Stich Fabric

What is Drop Stich Fabric

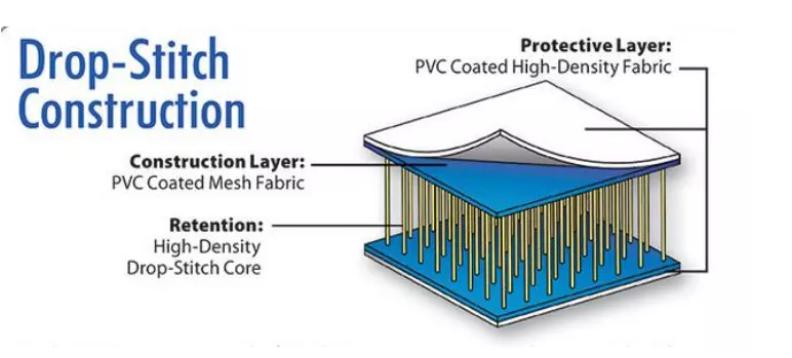

Dropstitch, also called “Double Wall Fabric”, is a 3D construction process by which thousands of yarns are simultaneously woven together to join both a top and bottom layer of fabric.The continuous and evenly spaced yarns between the fabric lock the pieces together, creating an incredibly strong unit that allows for an inflated bladder that maintains both dimensional stability and uniformity.

II: Drop Stitch Fabric Working Principle:

Do you know drop stitch fabric working principle? It’s a pretty amazing material we’re using to build NRS SUP Boards, our inflatable drift boats, and the GigBob Fishing Watercraft. Other uses for the technology have been floating docks, high-pressure rescue lifting bags and airplane wings!

This material lets us build inflatables with flat surfaces that can be inflated to rock-hard rigidity. You get hard-shell performance along with the easy transportation and storage of an inflatable. What makes this possible? Tens of thousands of fine threads.

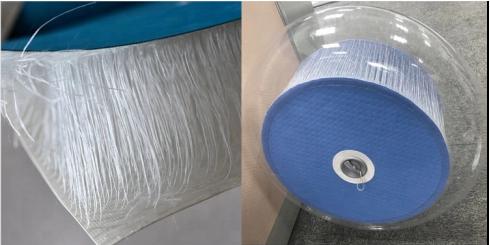

The process starts by joining two pieces of polyester woven support fabric with thousands of fine polyester thread lengths. This base material is made in strips from five to ten feet in width, and up to 400 needle heads may be used in the setup. Each needle sews a continuous, evenly spaced thread, back and forth between the two pieces of woven fabric, locking them together into an incredibly strong unit. These drop-stitch sewing machines are marvels of complexity. When a change is made in the spacing distance between the two pieces of woven fabric, it can take over 20 days to remove and replace the required needles.

Next, an air-tight coating is applied to the outer surfaces of both sides of the material. The sidewall material is made of polyester base fabric that is coated on both sides. Polyester thread is used throughout because it is strong, durable and has very little stretch.

The actual assembly process involves labor-intensive gluing of the sidewall material to the top and bottom pieces of the drop-stitch material. Then a wide seam tape is glued over each lap seam for a bomber, air-tight final product. What you have now is a super strong construction that can be inflated to pressures up to 20 pounds per square inch (psi).

III: Features:

a: Consistent inflation height

b: High burst strength

c: Flat surface after inflation

IV: Drop Stitch Fabric Applications:

It can be utilized in a number of applications, including inflatable boat bottoms, lift bags, rigid inflatable walls, rescue raft seating (inflated), structural membranes, inflatable screens, seat cushions, paddle boards, gymnastics flooring, and flotation devices. Rubber and polyurethane coatings and laminates, as well as additional coated textile layers, can be added to woven Dropstitch to meet application specific performance parameters.

1) Sporting goods, water sports and equipment, outdoor sports and equipment;

Yacht, boat cloth, inflatable boat bottom, inflatable cushion, SUP board, surfboard,

Car seat cushions, ski mats, gymnastic mats, outdoor camping mattresses;

2) Sound insulation cloth, sound insulation wall; construction noise reduction and noise prevention device;

3) Impact buffer device, buffer fabric;

4) Inflatable support, air cushion, etc. for lightweight cargo;

5) Inflatable billboard, inflatable movie screen

6) Multifunctional inflatable toys

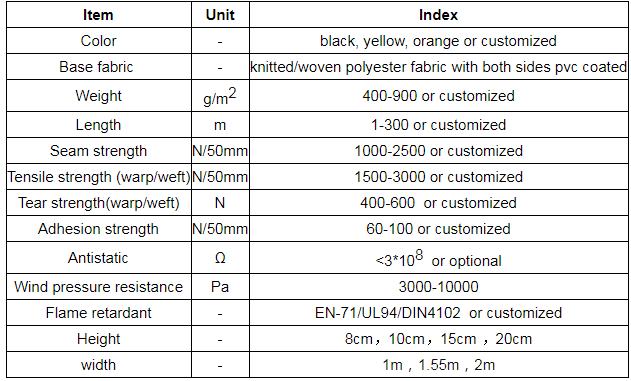

V: Drop Stitch Fabric Specifications:

VI: OPTIONS:

Fabric Heights Available: 0.75”, 2.5”, 4.0”, 6.5”, 8.0” and 11.5” Substrates Available: Nylon, Polyester, Kevlar® and blends Coatings Available: Rubber includes CR, CSM, CM, PU coatings and films. you can choose according actual applications.

VII:About Derflex:

Derflex is one of the oldest Drop Stitch Fabric manufacturer at China for more 20 years. we focus on the Drop Stitch Fabric manufacturering and our fabric export to all over the world.

Welcome to reach us at Ann Li with What”s APP&Wechat:+86-187-0192-0943 E-mail: ann@derflex.com