What is PVDF membrane for outdoor strcture

What is PVDF membrane for outdoor strcture?

I What is PVDF?

PVDF (PVF2 or Polyvinylidene fluoride or polyvinylidene difluoride) is a semi-crystalline, high purity thermoplastic fluoropolymer. With service temperatures up to 150°C, PVDF displays good combination of properties such as: 1 Exceptional chemical resistance; 2 High mechanical strength; 3 iezoelectric and pyroelectric properties; 4 as well as good processability

Its highly desirable insolubility and electrical properties result from the polarity of alternating CH2 and CF2 groups on the polymer chain.

PVDF is readily melt-processible and can be fabricated into parts by injection and compression molding. As a result, it is commonly employed in chemical processing equipment such as pumps, valves, pipes, tubes and fittings; sensors and actuators etc.

It has many electronic applications, especially as jacketing materials for plenum-rated cable used in voice and video devices and alarm systems. The low flame spread and smoke generation of PVDF is a prime asset in these applications.

PVDF is gaining acceptance as a binder for cathodes and anodes in lithium-ion batteries, and as a battery separator in lithium-ion polymer systems.

Emerging applications of PVDF include fuel cell membranes, and components for aircraft interiors and office automation equipment.

Molecular Structure of Polyvinylidene Fluoride (PVDF)

Thanks to its excellent combination of properties and processability, PVDF has become the largest volume of fluoropolymers after PTFE.

PVDF is available commercially in a wide range of melt flow rates and with various additives to enhance processing or end use properties.

II Introduction for PVDF membrane

PVDF is one of the most used membrane materials and has received great attentions thanks to its outstanding properties.

Properties such as thermal stability, chemical resistance and processability to form membranes make PVDF ideal for use in biomedical membrane applications and waste water treatment.

Thank to these features, applications of PVDF membranes are currently found in:

Pressure-driven water- and waste-treatment treatment (e.g., microfiltration, ultrafiltration and membrane bioreactor),

Membrane contactors operations (e.g., membrane distillation, acid gas absorption and stripping, volatile organic compounds removal)

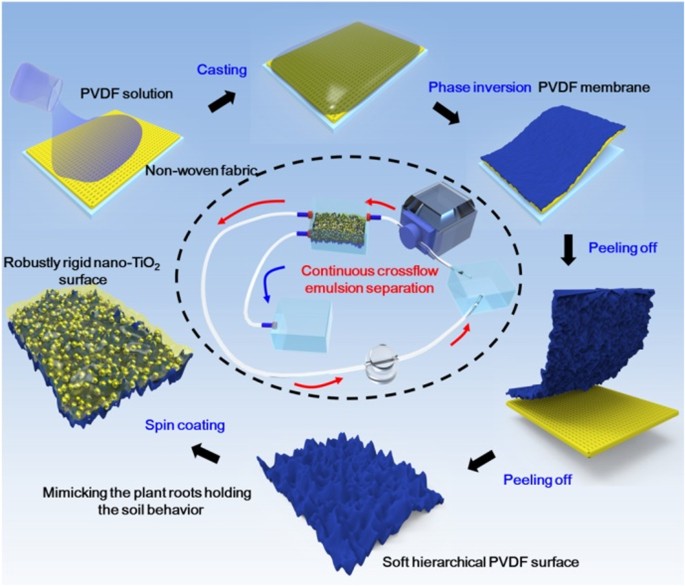

Today, most of the commercial membranes are produced via phase inversion method mainly because of its simplicity and flexible production scales (Hence, low cost of production)

But there are certain drawbacks associated with PVDF membranes such as wetting or fouling which can be easily solved by enhancing surface roughness or increasing the hydrophilic nature of the membrane. Though it cannot be absolutely prevented even with modification.

PVDF membranes can be used as separators in lithium ion batteries, as it has good chemical and thermal stability. These membrane have good mechanical strength, appropriate pore size and shutdown characteristics.

They are also used for the manufacture of ion-exchange membranes.

|

Product: |

PVDF Waterproofing Membrane for Roofing | |

|

Items |

Specification |

Test Standard |

|

Basic fabric |

1100D*1100D, 30*30 |

|

|

Thickness |

≥1mm +/-5% |

DIN53352 |

|

Weight |

1050gsm |

DIN53352 |

|

Breaking Strength |

L: 5800; W: 5400 (N/5CM) |

DIN53354 |

|

Tearing Strength |

L: 1000; W: 950 (N/5CM) |

DIN53356 |

|

Adhesion |

120 (N/5CM) |

DIN53357 |

III Features and Benefits for PVDF membrane

1 Mechanical strength of Immun-Blot PVDF membrane enables multiple reprobing of blots

2 Naturally hydrophobic support is ideal for western blotting because it ensures high signal with low background

3 Available in three formats:

Convenient precut membrane/blot absorbent filter paper sandwiches

Packs of precut membrane-only sheets

Economical rolls

IV Applications for PVDF membrane

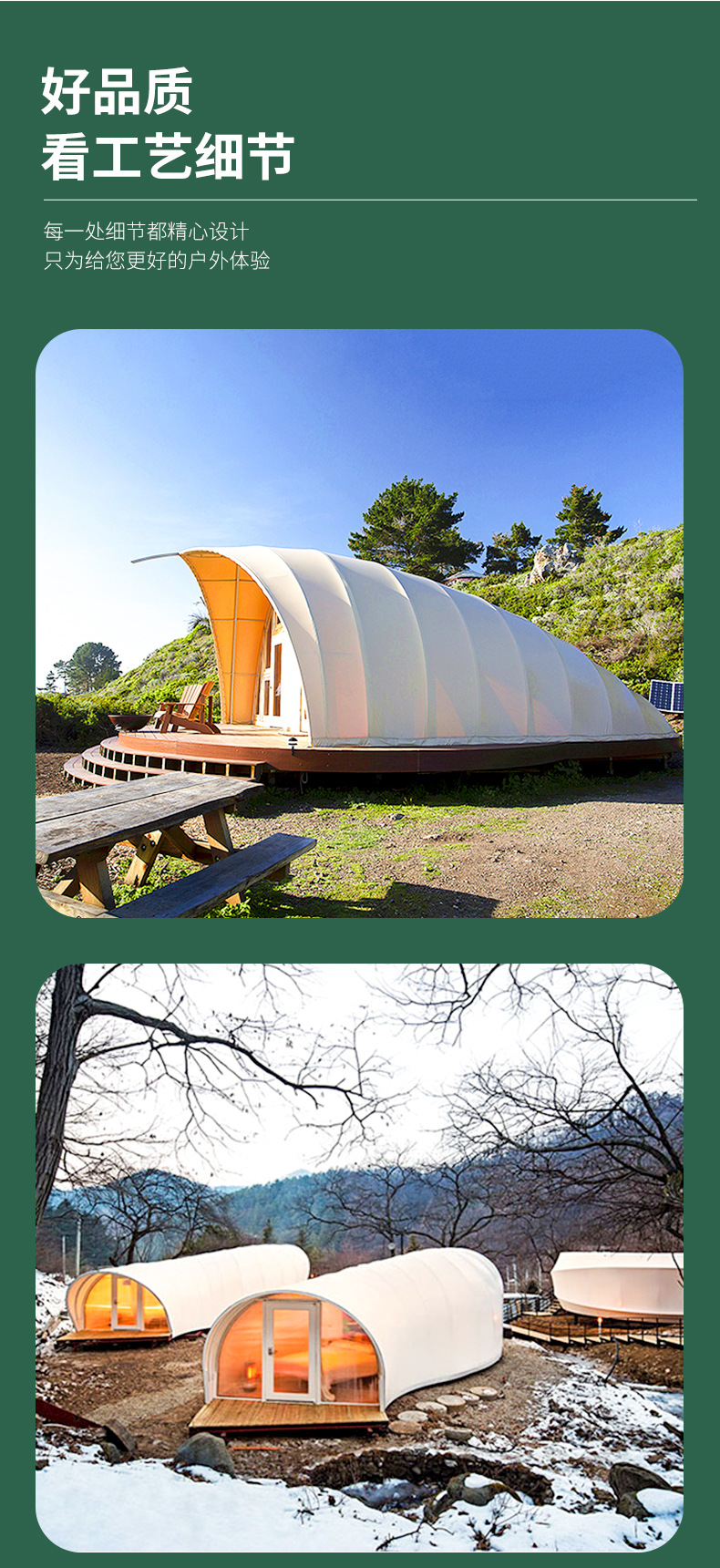

1 outdoor roof covering

2 outdoor parking

3 outdoor tent&house

V Introduction for DERFLEX

DERFLEX is a professional manufacturer of . We have our own factory, which is located in Zhejiang province, China , with 7 production lines, the supply capacity is 300,000sqm/month. We can produce different kinds of wide format digital printing media. Such as coated Frontlit, backlit, laminated PVC tarpaulin, blockout,mesh,self-adhesive vinyl, one-way vision, perforate vinyl, wide format print cotton canvas, PVC coated tarpaulin, photo paper, reflective material, projection screen fabric.

Our main product is PVC tarpaulin and it is widely used as truck/trailer/container cover, tents, pallet cover,strip garden fence,

awnings, inflatable products, adumbral materials for building facility and house.

For further business communication, welcome to contact:

Tel: +8617316447897(whatsapp&wechat)

Email: ellaine@derflex.com

Web: www.derflex.com