What is TPU tarpaulin cover

What is TPU tarpaulin cover?

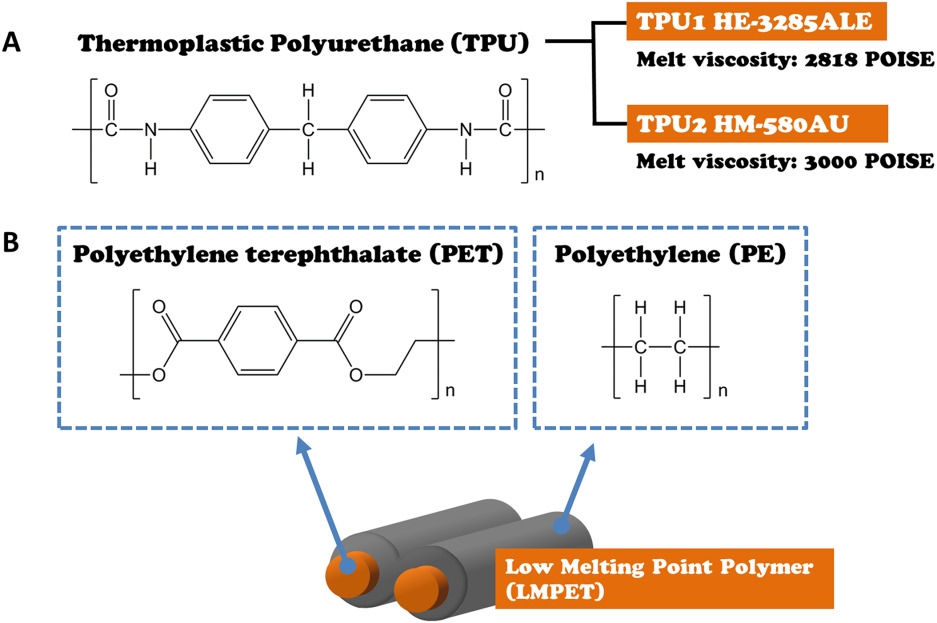

I What is TPU(Thermoplastic polyurethane)?

Thermoplastic polyurethane is any of a class of polyurethane plastics with many properties, including elasticity, transparency, and resistance to oil, grease,and abrasion.Technically, they are thermoplastic elastomers consisting of linear segmented block copolymers composed of hard and soft segments.

TPU is a block copolymer consisting of alternating sequences of hard and soft segments or domains formed by the reaction of (1) diisocyanates with short-chain diols (so-called chain extenders) and (2) diisocyanates with long-chain diols. By varying the ratio, structure and/or molecular weight of the reaction compounds, an enormous variety of different TPU can be produced. This allows urethane chemists to fine-tune the polymer's structure to the desired final properties of the material.

II Specifiction for TPU material

(A = excellent; B = good; C = acceptable; D = poor; F = very poor)

|

Property |

Polyester-based TPU |

Polyether-based TPU |

|

Abrasion resistance |

A |

A |

|

Mechanical properties |

A |

B |

|

Low temperature flexibility |

B |

A |

|

Heat aging |

B |

D |

|

Hydrolysis resistance |

D |

A |

|

Chemical resistance |

A |

C |

|

Microbial resistance |

D |

A |

|

Adhesion strength |

B |

D |

|

Injectability |

B |

B |

TPU is the right choice when a flexible at low temperatures and/or abrasion resistance TPE is requested. Polyether-based TPU in cases where additional excellent hydrolysis and microbial resistance is required, as well as in cases where extreme low-temperature flexibility is important. Ester-based TPU in cases the oil and greases resistance is more relevant.

When stable light colour and non-yellowing performance are required, aliphatic TPU based on aliphatic isocyanates is used.

BASF has pioneered crosslinking during TPU transformation, made possible by adding liquid crosslinkers or using a solid granulated additive masterbatch. Plant-based bio TPU has been developed for green thermoplastic elastomer applications by BASF, Merquinsa-Lubrizol and GRECO, marketed as Elastollan N, Pearlthane ECO and Isothane respectively.

III Properties of commercially available TPU:

1 high abrasion resistance

2 low-temperature performance

3 high shear strength

4 high elasticity

5 transparency

6 oil and grease resistance

The currently available TPUs can be divided mainly in two groups, based on soft segment chemistry:

1 polyester-based TPUs (mainly derived from adipic acid esters)

2 polyether-based TPUs (mainly based on tetrahydrofuran (THF) ethers).

IV Other application for TPU material

1 automotive instrument panels

2 caster wheels

3 power tools

4 sporting goods

5 medical devices

6 drive belts

7 footwear

8 inflatable rafts

9 a variety of extruded film, sheet and profile uses

10 flexible outer cases of devices like mobile phones and keyboard protectors

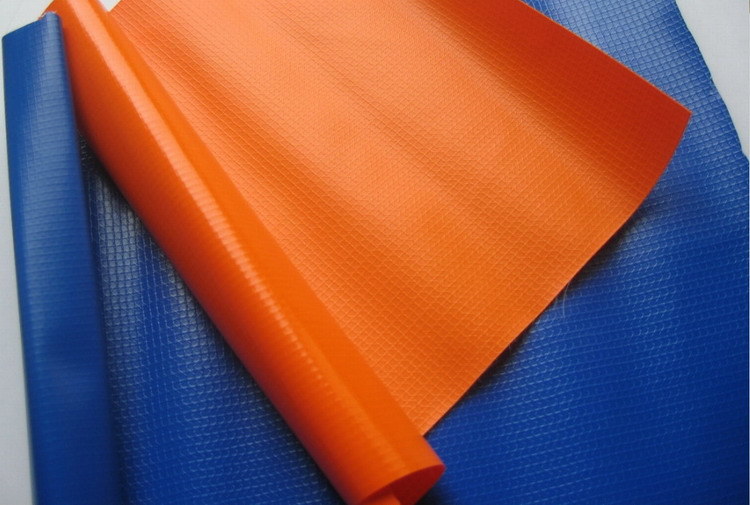

V Introduction for DERFLEX

DERFLEX is a professional manufacturer of . We have our own factory, which is located in Zhejiang province, China , with 7 production lines, the supply capacity is 300,000sqm/month. We can produce different kinds of wide format digital printing media. Such as coated Frontlit, backlit, laminated PVC tarpaulin, blockout,mesh,self-adhesive vinyl, one-way vision, perforate vinyl, wide format print cotton canvas, PVC coated tarpaulin, photo paper, reflective material, projection screen fabric.

Our main product is PVC tarpaulin and it is widely used as truck/trailer/container cover, tents, pallet cover,strip garden fence,

awnings, inflatable products, adumbral materials for building facility and house.

For further business communication, welcome to contact:

Tel: +8617316447897(whatsapp&wechat)

Email: ellaine@derflex.com

Web: www.derflex.com