PVC waterproof Membrane

PVC waterproof Membrane

I.What is PVC waterproof Membrane?

DER Polyvinyl Chloride (PVC) waterproofing membrane is a type of new high macro-molecular waterproofing membrane by adding plasticizer , filler ,anti-oxidizer , ultraviolet light absorber and other auxiliaries with polyvinyl chloride resins as raw material.

II. PVC Waterproof Membrane is divided into different types:

1. Reinforced PVC membrane (P)

2. Homogeneous PVC membrane (H)

3. Fabric Backing PVC membrane (L)

4. Self Adhesive PVC membrane (SA)

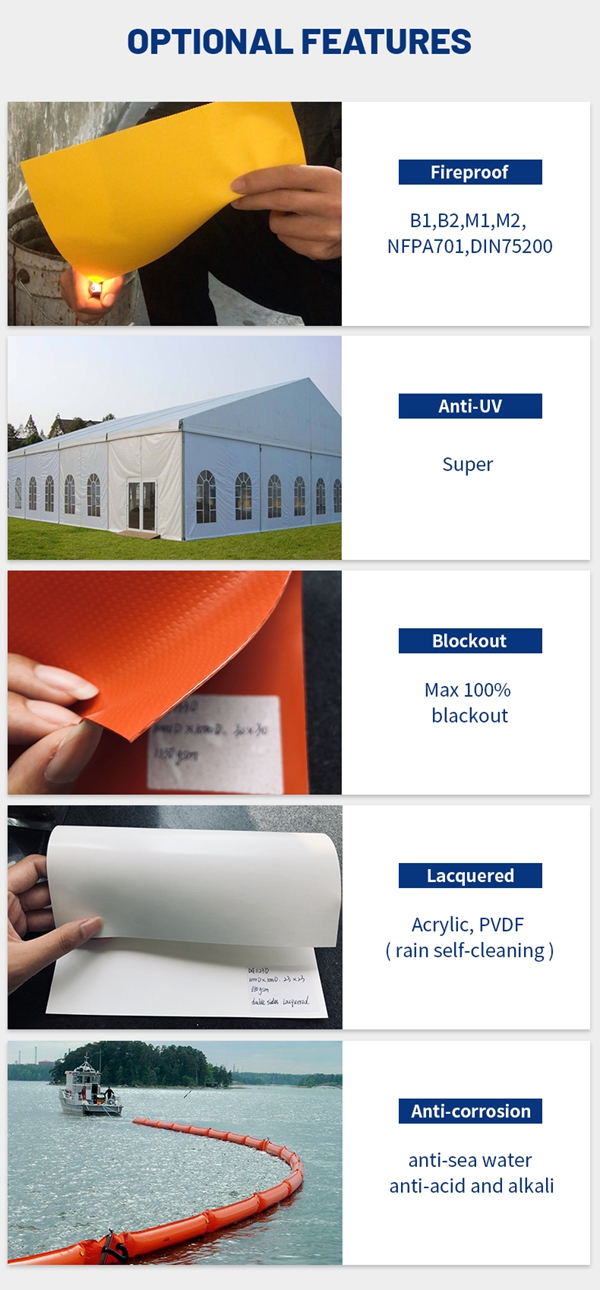

III. What are the advantages of PVC Waterproof Membrane?

1. Most finishes can be applied to the waterproofing membranes – this includes tiles on mortar beds, wearing slabs, pavers on pads, landscaping, decking, etc.

2. Suitable over most substrates including concrete, timber, steel, compressed fibre sheeting, etc. Can even be installed over damp substrates.

3. Safe to apply – they are either loose-laid or self-adhesive and every lap joint is hot air welded, no need for naked flames and torches.

5. Ideal for landscape applications including Green Roofs and Planter Boxes, as it is certified (FLL) and tested resistant to aggressive root penetrations. See Case study

4. Suitable for new and remedial applications such as below ground systems, balconies, exposed roofs, insulated roofs, planter boxes, green roofs etc.

5. Exceptional range of service temperature that allows them to remain flexible in both freezing & warm climates.

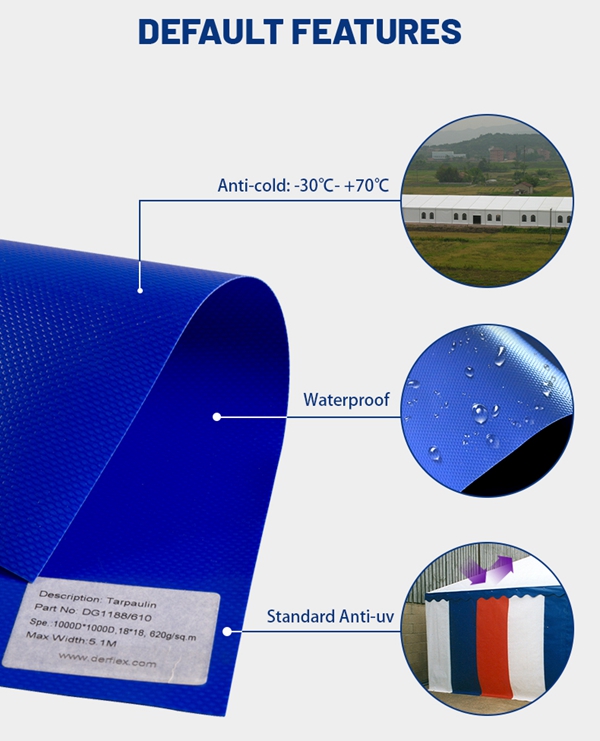

IV.Product Features

1. High tensile strength , good elongation , strong applicability for base expansion or cracking deformation .

2. Large width ,high construction efficiency , small product consumption .

3.Good diffusion of water vapor , easy discharge of condensate , easy discharge of moisture left in the substrate

4. Root penetration resistance , chemical corrosion resistance and aging resistance ;

5. maintain good flexibility even at -25℃

6.High Security without open flame installation

7. It used for exposed ,service life 10 years ; if unexposed used , the service life can be 50-100 years .

8. The artificial weathering time of DER PVC is not less than 4100 hours.

9.Anti-Wind reach 135 PSF

V.Technical Data Sheet

|

No. |

Test Item |

Index |

| |||

|

H |

L |

P |

| |||

|

1 |

The thickness of resin layer above the reinforcement fabric/ mm ≥ |

- |

- |

0.40 |

| |

|

2 |

Tensile property |

Maximum Tension N/cm ≥ |

- |

120 |

250 |

|

|

Tensile Strength Mpa ≥ |

10.0 |

- |

- |

| ||

|

Max Tension Elongation/ % ≥ |

- |

- |

15 |

| ||

|

Breaking Elongation/ %≥ |

200 |

150 |

- |

| ||

|

3 |

Heating treatment size change rate % ≤ |

2.0 |

1.0 |

0.5 |

| |

|

4 |

Low temperature bending |

-25 ℃ No.Crack |

| |||

|

5 |

Water impermeability |

0.3Mpa, 2h Impermeable |

| |||

|

6 |

Impact resistance |

0.5kg, m ,impermeable |

| |||

|

7 |

Anti-static load |

- |

- |

20kg impermeable |

| |

|

8 |

Seam peel strength N/mm ≥ |

4.0 |

4.0 |

3.0 |

| |

|

9 |

Right -angle tear strength N/mm ≥ |

50 |

- |

- |

| |

|

10 |

Trapezoid tear strength N ≥ |

- |

150 |

250 |

| |

|

11 |

Water absorbing capability (70 ℃, 168h)%≤ |

After soaking |

4.0 |

| ||

|

After airing |

-0.4 |

| ||||

|

12 |

Heat aging (115 ℃) |

Time/h |

672 |

|||

|

Appearance |

No bubble ,crack ,delamination , bonding and holes |

|||||

|

Max tensile retention %≥ |

- |

85 |

85 |

|||

|

Elongation retention % ≥ |

85 |

- |

- |

|||

|

Tensile strength ( Max tension on )retention %≥ |

- |

- |

80 |

|||

|

Breaking elongation retention /%≥ |

80 |

80 |

- |

|||

|

Cold bending |

-20 ℃ No. Cracking |

|||||

|

13 |

Chemical resistance |

Appearance |

No bubble ,crack ,delamination , bonding and holes |

|||

|

Max tensile retention %≥ |

- |

85 |

85 |

|||

|

Elongation retention % ≥ |

85 |

- |

- |

|||

|

Tensile strength ( Max tension on )retention %≥ |

- |

- |

80 |

|||

|

Breaking elongation retention /%≥ |

80 |

80 |

- |

|||

|

Cold bending |

-20 ℃ No. Cracking |

|||||

|

14 |

Artificial Climate accelerating aging |

Time/h |

1500 |

|||

|

Appearance |

No bubble ,crack ,delamination , bonding and holes |

|||||

|

Max tensile retention %≥ |

- |

85 |

85 |

|||

|

Elongation retention % ≥ |

85 |

- |

- |

|||

|

Tensile strength ( Max tension )retention %≥ |

- |

- |

80 |

|||

|

Breaking elongation retention /%≥ |

80 |

80 |

- |

|||

|

Cold bending |

-20 ℃ No. Cracking |

|||||

|

Single-ply roof membrane artificial climate accelerating , aging time is 2500h, no exposed used membrane no need to test artificial climate accelerating aging |

| |||||

VI.Standard Specification

1.Width : 2.0m/2.5m/3.0m,etc

2.Basic Thickness : 1.2mm , 1.5mm, 1.8 mm ,2.0mm

3.Length: 20m/30m/50m,etc.

VII. Application:

PVC Waterproof Membrane is a woven plastic-based material used to make poly tarps that can cover a variety of items. They are flexible enough to use in applications ranging from road transport covers to dome shelters and roof sheets. The poly tarp is very common because it is so versatile.

1. Truck cover, Top roof and side curtain.

2. Our door event tent(blockout)

3. Rain and sunshine shelter, playground.

4. Army tent, carriage tent and house building.

5. Construction structure.

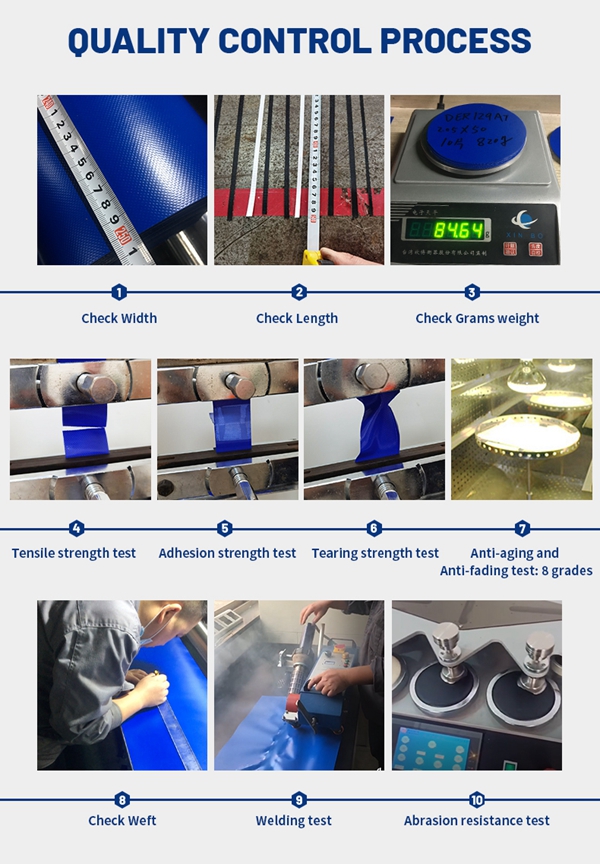

VIII.Our Factory

Derflex is one of the leading PVC Waterproof Membrane manufacturers in China with a history of 20 years. For more information please contact me:

Email: serena@derflex.com

Tele: +86 130 1285 4064 (WhatsApp and WeChat)

Facebook ID: https://www.facebook.com/serenazhu0809/