What is TPO Roofing membrane and how it works

What is TPO Roofing membrane and how it works

I: What is single-ply membrane roofing

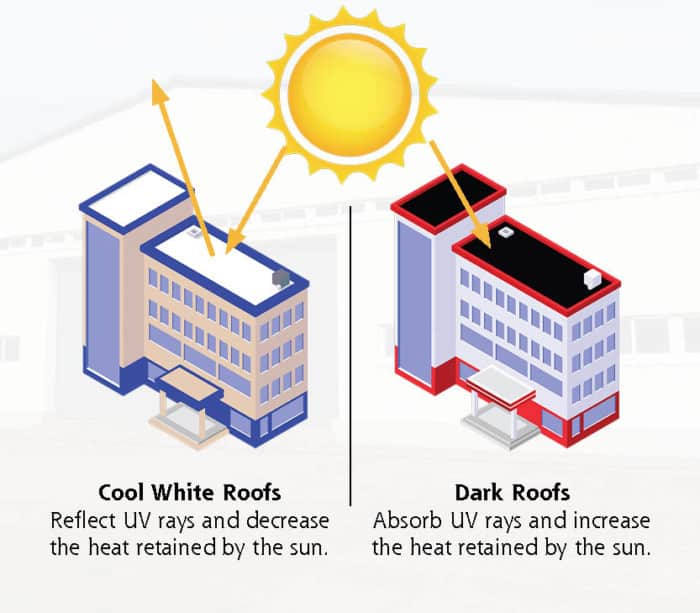

If you’ve seen a bright white roof, then you may be familiar with TPO roofing. As one of the most common roof types of big commercial facilities, TPO has some of the best energy savings for single-ply membrane roofing!

Single-Ply Membranes are sheets of rubber and other synthetics that can be ballasted, mechanically fastened, or chemically adhered to insulation creating a layer of protection on your commercial facility.

It is one of the most well-known types of commercial roofing material, there are several types to fit your budget and facility needs.

There are two main types of single-ply membrane commercial roofing: Thermoplastic Polyolefin (TPO) and Ethylene Propylene Diene Terpolymer (EPDM).

They differ in their chemical makeup, how they are installed, and their energy efficiencies.

II: What is TPO Roofing Membrane

Thermoplastic Polyolefin is a single-ply roofing membrane that is one of the fastest-growing commercial roofing systems on the market. TPO roofing systems are made up of a single layer of synthetics and reinforcing scrim that can be used to cover flat roofs. TPO membranes are manufactured in sheets that are 10, 12, or 20 feet wide. These sheets are then rolled up and taken to the commercial facility.

A TPO roof is a single-ply roofing system that consists of a polymer base, a fabric center, and a TPO top coating. It acts as a strong barrier against the elements, with optimal heat and UV resistance.

III: Advantages of TPO roofing membrane

Low-cost – TPO offers the same degree of protection as PVC roofs but at a fraction of the cost. This is particularly beneficial if you need to cover large amounts of roof area.

Reliable durability – TPO membranes resist mold growth, impacts, and punctures. It is made to be flexible to allow for a building’s thermal expansion and contraction which makes it ideal for buildings that need to house heat producing industrial equipment or refrigerated storage.

Simple installation – Single-ply roofing membranes can be manufactured in lightweight larger sheets that are easier to install with fewer seams, translating to less time required for installation.

Exceptional energy-efficiency – TPO has a reflective white surface which exceeds the EPA’s Energy Star requirements. This is attractive to businesses and homeowners that are looking to reduce energy costs while keeping the building comfortable.

Environmental sustainability – Going green? TPO roofs are an ideal option. They reduce the amount of energy waste from your HVAC system through their solar reflective properties. It’s also a completely recyclable roofing option.

IV: TPO Roofing Installation

After the existing substrate is prepared, either by cleaning or removing the existing roof, the insulation is installed. There are a few types of insulation options the facility manager/owner can choose from:

Polyisocyanurate (Polyiso) – The most used insulation type for roofing applications, Polyiso is more expensive but pays off with a higher R-value rating.

Expanded Polystyrene (EPS) – With the highest R-value per dollar, EPS is used for roof, wall and floor insulation. EPS can be used for ground contact and does not retain water over time.

Extruded Polystyrene (XPS) – Usually defined by the blue, green or pink color, XPS falls in-between Polyiso and EPS in the range of price and performance. XPS is semipermeable with a perm rating of 1.

The TPO membrane can be attached to the cover board with a bonding adhesive or mechanically fastened. When the membrane is rolled out, the contractor then returns and uses a hot-air gun to hot air weld the seams together.

Here’s a video of the West Roofing Systems team installing a TPO Single-Ply Membrane Roofing System:

V: TPO Roofing Costs

For an average 20,000 sq. foot commercial roof, it will usually cost between $3.50 and $7.50 per square foot in materials and labor to install a typical single-ply membrane commercial roofing system.

To get the best rubber roofing prices, you will need to consider these key factors:

The size of your roof

The condition of the existing roof

Access to roof

Insulation choice

Membrane choice

Installation choice

Roof penetrations

Type of warranty

VI: How TPO Roofing Saves Money

The most common TPO material is bright white with highly reflective properties. This bright white roof installation can reflect UV rays and heat from the building, saving money during the summer months from decreased energy usage to cool the building interior.

VII: How is a TPO roof repaired?

A TPO will last approximately 15-20 years. During this time, seams can rip apart, flashings can fail, the membrane can become punctured, etc. which will cause a roof leak.

The first sign of a TPO roof needing repair is when water has begun to enter the building. This usually happens because the seams have been ripped open, allowing water to enter the roofing insulation.

Once the insulation accrues so much water, it enters your roofing deck and eventually starts leaking on the inside of your building.

At this stage, it’s time to call a commercial roofing contractor to perform a roofing inspection.

During the inspection, a roofing contractor will be able to tell:

Where water is entering your insulation

How old the TPO roof is

How many layers the roof has

What condition the seams are in

What comes out of this conversation is what repair options the building owner has. Say the roof is 12 years old and the seams are slightly uplifted, like this:

On this roof, the seams are getting close to the point of failure. If something isn’t done now (or very soon), with every wind gust, the seams are separating further, which is allowing more water to enter the insulation.

A roofing contractor will perform an infrared inspection to check the amount of saturation that’s in the insulation.

They will come out to your roof about 30 minutes after the sun goes down. At this time, the surface of the roof will be cooler than the water that’s saturated in your insulation.

The infrared camera will detect the heat difference and the contractor will mark those areas with spray paint.

VI: About Derflex:

Derflex is one of the oldest TPO Roofing membrane manufacturer at China for more than 20 years.

Welcome to reach us at Ann Li with What”s APP&Wechat:+86-187-0192-0943 E-mail: ann@derflex.com