What is inflatable rafts fabric

What is inflatable rafts fabric?

I Introduction for pvc inflatable rafts fabric.

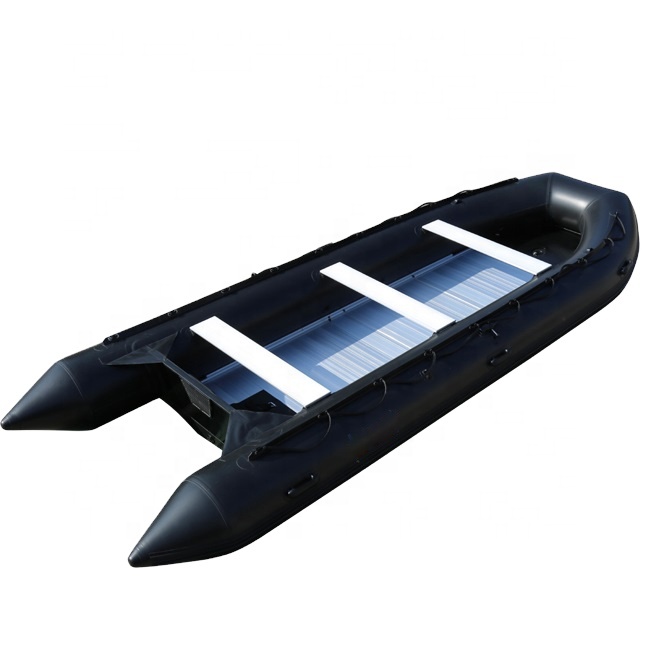

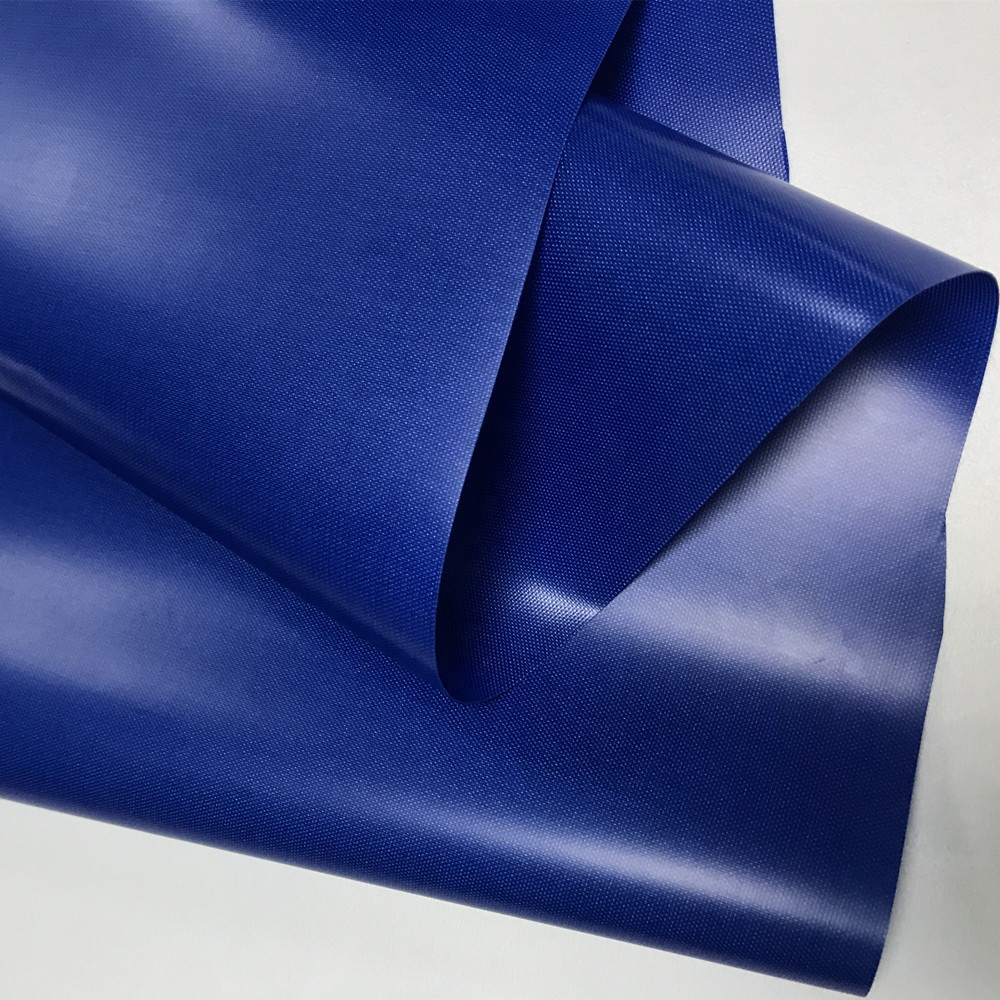

The PVC used to make inflatable boats is essentially the same stuff used to make plastic plumbing pipes. The major difference is that the material used to make inflatable boat PVC fabrics airtight has various component added to make it more flexible and softer than the average plumbing pipe. Dyes are also added to give the PVC fabric particular colors.

PVC-covered inflatable boats fabric is cheaper than Hypalon fabric, but the big advantage of PVC fabric over Hypalon fabric is that seams can be cold welded quickly and efficiently. Seams on a Hypalon or Hypalon boats, on the other hand, must be hand-glued by highly skilled workers using a glue pot and brush.

However, PVC dose has several issues as a inflatable boat material. It is photodegradabie. In direct sun light PVC fabric slowly breaks down. If you leave a PVC inflaable boat out in the sun for long period of time, it will begin to fade out or become sticky. Many quality manufacturers of PVC inflatable boats protect their products with ultraviolet coatings similar to the UVAs (ultraviolet absorbers) in marine varnishes and paints.

II Specification for PVC inflatable boats fabric

|

item |

value |

|

Supply Type |

Make-to-Order |

|

Material |

PVC coated Fabric |

|

Weight |

650gsm~2200gsm |

|

Thickness |

Medium Weight |

|

Feature |

Waterproof, Anti-UV, Abrasion-Resistant |

|

Technics |

nonwoven |

|

Style |

Plain |

|

Type |

Oxford Fabric |

|

Width |

1550mm- 2300mm |

|

Pattern |

Embossed |

|

Use |

Industry, Sportswear, Outdoor-Industry, outdoor water sports and security |

|

Coated Type |

PVC Laminated |

|

Model Number |

SIJIA Inflatable Material |

|

Color |

multicolor |

|

Thickness |

0.52mm-1.8mm |

|

Trade Marks |

SIJIATEX |

|

Original |

Fuzhou,China |

|

Package |

50m/roll |

To make inflatable PVC boats ready for the water, they have to add a bunch of chemicals. Things like pigments, plasticizers, UV stabilizers, and heat stabilizers are all added to the boat fabric. While all these extra chemicals make the boat work better, they’re not very environmentally friendly. Another downside is that these chemicals leach out over time, meaning they lose their effect and slowly but steadily break down the PVC fabric of your boat.

Pros:

1 PVC is easy to repair by either gluing or welding new sheets of PVC.

2 It’s very abrasion resistant when wet.

3 Finding cheap inflatables has never been easier thanks to PVC.

Cons:

1 PVC has almost no abrasion resistance when dry.

2 It’s not as UV resistant as other fabrics.

3 Inflatable PVC boats deteriorate over time, meaning they become brittle and fragile.

IV Types of Fabrics used for Making Inflatable Boats or kayaks

Inflatable boats were mostly made with rubber for a long time. However, nowadays, most of the boats are made of plastic polymers like PVC (polyvinyl chloride fabric). New materials, such as Hypalon or Neoprene are synthetic rubbers that are gaining momentum due to higher resistance and efficiency. Here, we see some of the popular materials being used for manufacturing inflatable boats.

1 PVC fabric

PVC is a vinyl polymer chemically known as polyvinyl chloride. It is a type of plastic that can be thermo-bonded or glued onto polyester or nylon.

PVC fabrics are the popular fabrics owing to their strength, elasticity, resistance.

It is also easier to repair and has a higher resistance to ultraviolet rays.

It has absolute water and sufficient chemical resistance.

PVC is also a largely affordable and cost-efficient option as opposed to other fabric options.

It is available in a wide array of colour options.

2 Hypalon or Neoprene fabric

Hypalon is a synthetic rubber material and has many applications in the marine industry.

It is a material with an excellent capacity for holding air, which makes it a great option for inflatable boats.

It is oil resistant.

It can be coated on polyester or nylon fabric in addition to an interior coating of neoprene. It has proved to be a very reliable and durable type of fabric.

Hypalon fabric lasts for over a decade and endures the harsh weather conditions.

Since Hypalon has greater strength and durability, inflatable boats made out of this fabric are more expensive.

To construct an inflatable boat, it is necessary to have a proper design, construction, and engineering to ensure a proper structure. However, the structure of the inflatable boat depends on the building material. Materials used to construct an inflatable boat play a crucial role since these boats don’t have much of a frame. It depends on the fabric to endure and carry the load of the structure.

Due to these reasons, SHM uses Hypalon or Neoprene fabric in the construction of its inflatable boats. Here are a few advantages of Hypalon over other materials.

V Introduction for DERFLEX

DERFLEX is a professional manufacturer of . We have our own factory, which is located in Zhejiang province, China , with 7 production lines, the supply capacity is 300,000sqm/month. We can produce different kinds of wide format digital printing media. Such as coated Frontlit, backlit, laminated PVC tarpaulin, blockout,mesh,self-adhesive vinyl, one-way vision, perforate vinyl, wide format print cotton canvas, PVC coated tarpaulin, photo paper, reflective material, projection screen fabric.

Our main product is PVC tarpaulin and it is widely used as truck/trailer/container cover, tents, pallet cover,strip garden fence,

awnings, inflatable products, adumbral materials for building facility and house.

For further business communication, welcome to contact:

Tel: +8617316447897(whatsapp&wechat)

Email: ellaine@derflex.com

Web: www.derflex.com