I. What is PVC coated fabric?

PVC coated tarpaulin fabric, is produced by 100% polyester fabric, double side coated with high quality PVC raw material, to make the vinyl coated fabrics have good waterproofing and all level blockout characters, at the same time, for the application of polyester fabric, it gives good tearing and breaking strength to the PVC coated fabric. It can be produced in different weight and thicknesses, to meet customer requirement

II. Production process of PVC tarpaulin fabric:

There are several types of production of PVC coated fabric material:

1. Knife coated PVC fabric:

It is liquid PVC spread on high density woven polyester fabric, with a knife above the fabric, keep the top of fabric with same thickness PVC coated, then going to heater and cooler process to solidate the PVC onto polyester fabric.

Main advantages and disadvantages: Higher peeling strength because the liquid PVC has more falling into polyester fabric; at the same time, as the high temperature of the PVC during heating process, the fabric would be a little fragile and it is a little less tearing strength compared to other production process.

2. Hot melt coated PVC fabric:

It is polyester fabric and PVC film laminated together, during the process, PVC film and the polyester fabric are brushed with strong glue to adhere together, and before laminating, PVC film is heated to semi-melted status, in this case, the peeling strength is strengthened while it has more air tightness compared to knife coating PVC fabric, it is ideal products for inflatables.

3. Hot laminated PVC fabric:

Hot lamination is a knitted polyester fabric laminated with PVC film under temperature 100-120℃. It is used for temporary tents and awnings.

4. Cold Laminated PVC fabric:

Cold lamination is a knitted polyester fabric laminated with PVC film under temperature 80-100℃. It is used for temporary tents and awnings.

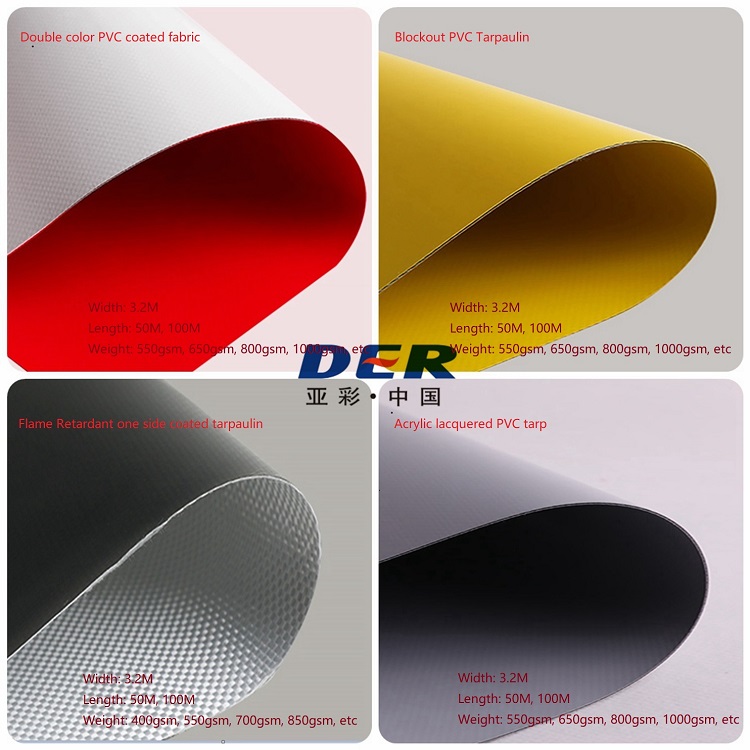

III. Types of PVC coated polyester fabric:

There are many types of PVC tarpaulin fabrics. With special treatment on the material, it can be used for different applications:

1. Anti-scratch PVC coated fabric

Regularly used for outdoor covers, which need to have friction with object surface.

2. Flame-Retardant PVC coated fabric

Good choice for flexible speed doors, industrial aprons for work house application, and some areas which have requirement of no burning material applied.

3. Anti-static PVC coated fabric

Used for mining, gas station, and some other applications which has Combustible gas environments.

4. Air-tight PVC coated fabric

For outdoor inflatables, water/oil bladders which cannot leak after long time of storage.

5. Super strong PVC coated fabric

For weighing bags, container bags, and water tanks, which has exclusive water pressure, and need extremely good tearing and breaking strength from the PVC tarpaulin applied

6. Double side lacquered PVC coated fabric

For outdoor tents and awnings, especially membrane structures, it need very good anti-UV characters to last at least 5 years without fading or becoming yellowish.

IV. Most popular Vinyl coated fabrics types:

1. PVC coated fabric for truck cover, also known as truck tarps, it is a 18oz tarpaulin with anti-scratch coating, twist yarn to make it possible for repeat use, main specifications:

|

item |

value |

unit |

test method |

|

Basic fabric |

1000D*1000D |

Denier |

|

|

construction |

20*20 |

Threads/Inch2 |

|

|

total weight |

610 |

gsm |

DIN53352 |

|

Breaking strength |

L :2550 |

N/ |

DIN53354 |

|

W:2350 | |||

|

Tearing strength |

L:260 |

N/ |

DIN53356 |

|

W:255 | |||

|

Adhesion |

120 |

N/ |

DIN53357 |

|

Applicable |

-30/+70 |

℃ |

|

|

FR |

B1/B2/M1/M2/NFPA701(According to customer request) | ||

2. PVC coated fabric for tents, or tent material, it is 900gsm PVC coated fabric, main specifications as following:

|

item |

value |

unit |

test method |

|

Basic fabric |

1000D*1000D |

Denier |

DIN53353 |

|

Construction |

30*30 |

|

DIN53353 |

|

Total weight |

900 |

Gsm |

DIN53352 |

|

Breaking strength |

L:4000 |

N/ |

DIN53356 |

|

W:3800 | |||

|

Tearing strength |

L:500 |

N/ |

DIN53357 |

|

W:450 | |||

|

Adhesion |

≥140 |

N/ |

DIN53357 |

|

Lacquering |

Acrylic/PVDF(According to customer request) | ||

|

Fire-retardant |

B1/B2/M2/NFPA701 (According to customer request) | ||

|

Eco-friendly |

EN71/Reach | ||

|

Temp resistance |

-30~70℃ |

|

|

3. PVC coated fabric for inflatable castles, or PVC inflatable tarpaulin, is especially used for inflatable products, main specifications as following:

|

item |

value |

unit |

test method |

|

Basic fabric |

1000D*1000D |

Denier |

|

|

construction |

23*23 |

Threads/Inch2 |

|

|

total weight |

820 |

gsm |

DIN53352 |

|

Breaking strength |

L :3380 |

N/ |

DIN53354 |

|

W:2770 | |||

|

Tearing strength |

L:350 |

N/ |

DIN53356 |

|

W:280 | |||

|

Adhesion |

200 |

N/ |

DIN53357 |

|

Applicable |

-30—70 |

℃ |

|

V. Applications of PVC coated textile:

PVC coated fabriccan be used for all industrial flexible storage, covering applications.

VI. How to choose PVC fabric rolls for your projects

1. Application area: It is very important to know what is the most important for your application, what is the environment when you use the PVC tarpaulin

2. Knowledge of PVC coated fabrics, how to use, how to weld, how to install, how to produce to meet your requirement, if possible, go to several factories to know more about the PVC coated fabric.

3. Customization: Colors, thicknesses, glossy or matt, etc, which ones is more popular in local market.

4. Some other factors that may influence your choice, but first you should have enough information by yourself.

VII.How to choose a good PVC coated fabrics factory

1. All factories think their products are the best in certain area, you have to choose a person who is more reliable, that means, he must be professional on the products he sells, and he knows more than what you have known by yourself.

2. A good factory always has good inspection team during their production.

3. Professional on packing, delivery, export process, etc, it is good service to save your time.

4. Some certificates are required.

VIII. Advantages of DERFLEX PVC coated canvas:

1. Production and exporting experience over 20 years, we are reputed in most of EU, US, South America, Africa, etc

2. We have 3 factories already, and new factory is in process, estimate to start production beginning of 2023, to keep good volume to supplier top brands.

3. Stable Raw Material supply in good price

4. Perfect inspection series, to make 0 mistake during production.

For more information, please contact

+8615601786499