Boat Tarp All you need to know

I: What are the types of inflatable sport boats fabric

Inflatable sport boats fabrics mainly divides into 3 different categories: Polyvinyl Chloride (PVC) fabrics, Hypalon® fabrics or Polyurethane (PU) fabrics. All 3 boat fabrics are made by a coating polymer (PVC, Hypalon or PU) together with a supporting fabric; polyamid (Nylon) or polyester. All boat fabrics can be found with both types.

In the production of the final fabric the polymer is added to the supporting fabric either by extrusion or by a coated hot roller. When adding the polymer with a coated hot roller the tear strength of the fabrics is considerably higher than that of fabrics made by extrusion.

II: What is PVC inflatable fabric for sport boats

Polyvinyl chloride, commonly abbreviated PVC, is a widely used thermoplastic polymer. PVC can be made softer and more flexible by the addition of plasticizers, the most widely used being phthalates. In this form, it is used in clothing and upholstery, and to make flexible hoses, tubing and of cause pontoons.

The plasticizer in PVC has the great disadvantage that it in time (and especially when exposed to UV-radiation) decomposes and leaves the pontoon fabric hard, crisp, and mechanically much weakened. Stories of pontoons that ‘rotten in the sun’ are stories of old PVC pontoons exposed to sun.

Fabrics made by PVC are hard to joint, you can only use a single cure adhesive, which is PU ester. Some manufacturers use high mechanical pressure, high frequency welding or electronically welding, which makes mass production of boats possible in a large scale with machinery and inexperienced labour.

PVC fabrics are produced in a larger palette of colors than fabrics made of Hypalon® and Polyurethane. PVC is considered the poorest material for pontoon production and is mainly used in cheap mass-produced boats.

III: inflatable PVC fabric features for sport boat:

Advanatges: inexpensive. The production of PVC fabric is easier than when using both Hypalon® or Polyurethane.

Less Expensive

Stiffer material

Less flex in the boat in the boat in harder whitewater

Often have drop stitched floors which is great for standing and casting when angling

Disadvantages:

not particularly durable, can crack when rolled in cold temperatures, tend to be mass produced so these boats are known for quality issues.

A cheaper material than Hypalon® and Polyurethane has a short lifetime when exposed to sunlight (UV).

Contains chlorine

The strength and the ability to resist tear and wear is radically poorer than that of Hypalon® or Polyurethane.

IV: What is Hypalon Fabric for sport boats

Hypalon is for chlorosulfonated polyethylene (CSPE) synthetic rubber (CSM) noted for its resistance to chemicals, temperature extremes, and ultraviolet light.

Along with PVC, it is one of the most common materials used to make inflatable boats. Hypalon has become the common name for all kinds of CSM.

Hypalon has demonstrated long life in harsh environments and is known for its air tightness and resistance towards different chemicals among others oil pollution.

Hypalon fabrics is made of layers of polyester or polyamide and supplied with an internal layer of neoprene. Hypalon has throughout the years proven to be a reliable and solid material for RIB pontoons.

Hypalon is considered the second-best pontoon material. However, it is used by many manufacturers as it is technically easier to produce boats with Hypalon fabric than Polyurethane fabric.

V: Hypalon Fabric features for sport boats:

Advantages:

More supple material

Smaller roll/pack size

Generally lighter overall

Better UV resistance

Longer lasting material

Better abrasion resistance

Better chemical resistance

Typically carry a longer warranty than PVC rafts

Unaffected by extreme temperatures (ie. when stored in the cold over winter)

Easy to roll, relatively easy to field repair, and the material has a long life.

Hypalon shows a good resistance when exposed to sunlight (UV) and chemicals.

Hypalon is considered the second-best material in manufacturing pontoons. More abrasion and puncture resistant than PVC, but less than urethane.

Disadvantages:

The fabric is more expensive compared to PVC.

glued together (instead of welded) so it can come unglued sometimes.

Has a porous surface and a tendency of getting scratched, dirty and dull.

When used in production the Hypalon fabric is not as technically demanding a material as Polyurethane.

Contains chlorine.

Advantages:

More supple material

Smaller roll/pack size

Generally lighter overall

Better UV resistance

Longer lasting material

Better abrasion resistance

Better chemical resistance

Typically carry a longer warranty than PVC rafts

Unaffected by extreme temperatures (ie. when stored in the cold over winter)

Easy to roll, relatively easy to field repair, and the material has a long life.

Hypalon shows a good resistance when exposed to sunlight (UV) and chemicals.

Hypalon is considered the second-best material in manufacturing pontoons. More abrasion and puncture resistant than PVC, but less than urethane.

Disadvantages:

The fabric is more expensive compared to PVC.

glued together (instead of welded) so it can come unglued sometimes.

Has a porous surface and a tendency of getting scratched, dirty and dull.

When used in production the Hypalon fabric is not as technically demanding a material as Polyurethane.

Contains chlorine.

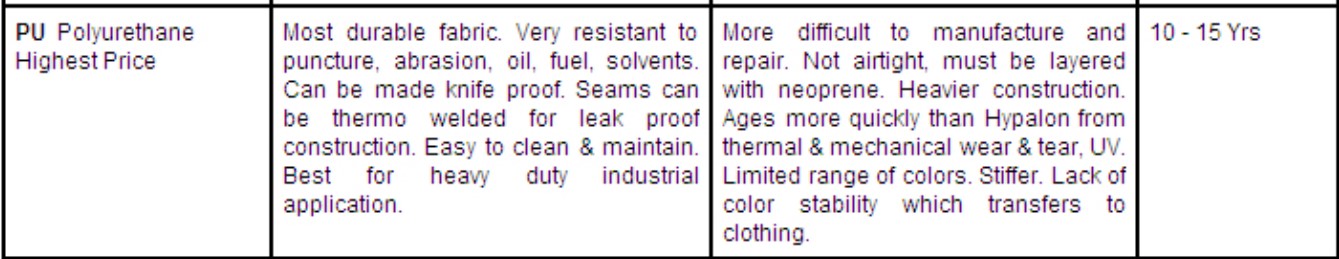

VI: What is PU Fabric for sport boats

Polyurethane, commonly abbreviated PU. Polyurethanes are in the class of compounds called reaction polymers, which include epoxies, unsaturated polyesters, and phenolics.

100% Polyurethane material offers four times the abrasion resistance and greater tear or tensile strength compared to Hypalon® and much stronger than PVC.

Polyurethane fabrics have excellent welding properties. Both hot air/pressure rotary Welders and Radio Frequency Welders can be used to join the material together in a molten state, thereby creating an incredibly strong bond.

The combination of the elastomeric properties of Urethane and the resiliency properties of nylon allows the material to repeatedly stretch and still recover to show its original properties.

Polyurethane was originally manufactured in the early 70’s as fuel cell bladders for helicopter fuel for military use and has proved to be the ideal material for boat pontoons.

VII: PU Fabric features for sports boats:

Advantages: Slips nicely over rocks, most durable fabric, lightweight, best puncture and tear resistance, durable. The welding process they use to make these boats is bomber.

Polyurethane has an incredibly long lifetime.

Resist mechanically wear and tear very well.

The latest polyurethane fabrics shows an excellent resistance when exposed to sunlight (UV) and chemicals – even better than Hypalon.

Polyurethane is the strongest air-holding material available.

Easy to repair.

Polyurethane is less damaging to the environment

Contains NO chlorine

Demanding to use in production.

Polyurethane is the best material for pontoons and is recommended for professional boats.

Disadvantages: Fairly expensive, tough to roll and transport, difficult to field repair.

VIII: Comparison among the different sport boats fabric

Although there are some pretty major differences in the 3 materials, they are both durable and well suited for the rigours of sport boats.

Derflex is one of the professional raft material manufacturer in China with experience over 20 years. we focus on manufacturing and exploring different raft materials.

Our inflatable fabric for sport boats advantages: Wear resistance, low temperature resistance -35 ℃, still tear resistance; Anti UV, Anti sharp puncture.

IX: About DERFLEX

Our team would love to chat further about these materials or any other raft related questions you have. Check out our contact info below for more details. Welcome to reach us at Ann Li (What”s APP&Wechat): +86-187-0192-0943 E-mail: ann@derflex.com