Production Process of PVC Laminated Tarpaulin

The production process of PVC laminated tarpaulin involves multiple steps to ensure durability, weather resistance, and adhesion between layers. Below is a detailed breakdown of the manufacturing process:

1. Raw Material Preparation

Base Fabric: Typically polyester (PET) or nylon woven fabric (e.g., 500D, 1000D) for strength.

PVC Resin: The primary coating material, mixed with additives:

Plasticizers (e.g., DINP, DOP) for flexibility.

Stabilizers (e.g., calcium-zinc) for heat resistance.

UV inhibitors for sunlight protection.

Flame retardants (if required).

Color pigments (for desired appearance).

2. Fabric Pre-Treatment

Heat Setting: The fabric passes through an oven to remove moisture and wrinkles.

Scorching (Optional): Burns off loose fibers for smoother lamination.

Primer Coating (Optional): Enhances PVC adhesion to the fabric.

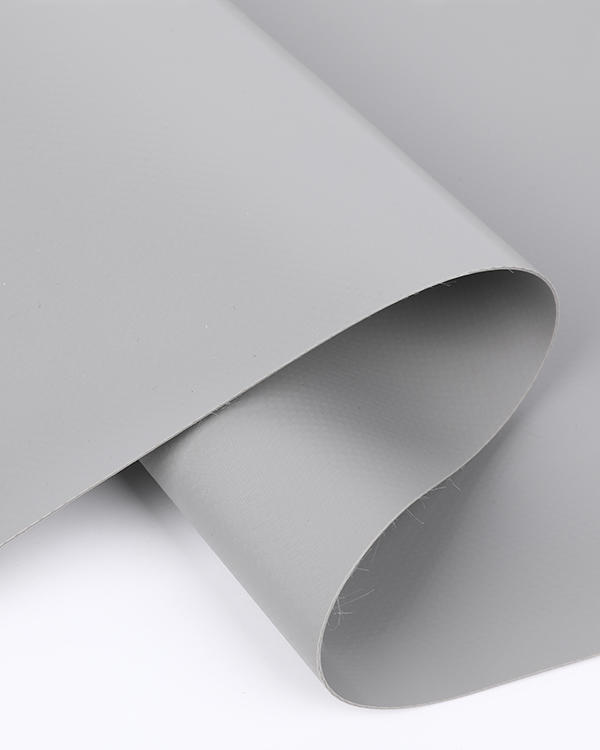

3. PVC Film Preparation

The PVC resin mix is extruded into a thin, uniform film.

Calendering: The molten PVC is pressed into sheets of precise thickness (e.g., 0.3mm–0.8mm).

4. Lamination Process

Method 1: Hot Melt Lamination (Most Common)

The PVC film is placed over the fabric.

Passed through heated rollers (120–200°C) under high pressure.

The heat melts the PVC, bonding it permanently to the fabric.

Method 2: Adhesive Lamination

A thermosetting adhesive (e.g., PU or acrylic) is applied between the PVC film and fabric.

Cured under heat for a strong chemical bond.

5. Cooling & Solidification

The laminated fabric is cooled rapidly to lock the layers together.

Ensures no warping or delamination.

6. Surface Finishing

Embossing: Rollers add texture (e.g., matte, glossy, or anti-slip patterns).

Top Coating (Optional):

PVDF coating for enhanced UV resistance.

Acrylic coating for better waterproofing.

7. Quality Control Tests

Peeling Strength Test (ASTM D751/ISO 2411) – Ensures layers won’t separate.

Water Resistance Test (ISO 811) – Checks for leaks.

Tensile Strength Test (ISO 13934-1) – Measures fabric durability.

Flame Retardancy Test (EN 13501/NFPA 701) – For safety compliance.

8. Cutting & Sewin

The laminated fabric is cut to size.

Edges are hemmed, welded, or reinforced with webbing/keder strips.

Grommets or eyelets are added for tie-downs.

9. Final Inspection & Packaging

Visual checks for defects (bubbles, uneven coating).

Rolled or folded for shipping.

Key Factors Affecting Quality

Temperature/Pressure Control: Critical for consistent lamination.

PVC Formula: Balances flexibility, UV resistance, and adhesion.

Fabric Quality: High-denier polyester ensures tear resistance.

Applications of PVC Laminated Tarpaulin

Heavy-duty truck covers

Industrial curtains

Marine and stadium roofing

Military and disaster relief tents