What is difference between PVC coated tarpaulin and PVC laminated tarpaulin

The key difference between PVC coated tarpaulin and PVC laminated tarpaulin lies in their manufacturing process, structure, and performance characteristics. Here’s a detailed comparison:

1. Manufacturing Process

PVC Coated Tarpaulin:

The base fabric (polyester or nylon) is dipped or sprayed with liquid PVC, then cured.

The coating penetrates the fabric fibers, creating a single-layer bond.

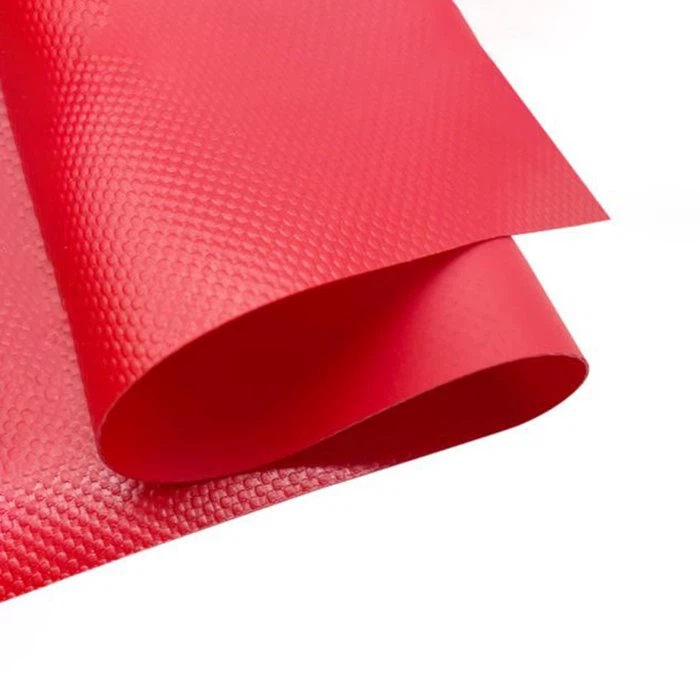

PVC Laminated Tarpaulin:

A pre-made PVC film is heat-pressed onto the fabric (like a sandwich).

Involves adhesive layers for a stronger, multi-layered structure.

2. Material Structure

|

Feature |

PVC Coated Tarpaulin |

PVC Laminated Tarpaulin |

|

Layers |

1 layer (fabric + coating) |

2+ layers (fabric + adhesive + PVC film) |

|

Thickness |

Usually thinner |

Thicker, more rigid |

|

Flexibility |

More flexible |

Stiffer, less pliable |

3. Performance Differences

|

Property |

PVC Coated |

PVC Laminated |

|

Waterproofing |

Good, but coating can wear off |

Superior (film blocks water completely) |

|

Durability |

Prone to peeling over time |

More resistant to delamination |

|

UV Resistance |

Moderate (depends on coating) |

Excellent (film adds protection) |

|

Tear Strength |

Lower (single-layer bond) |

Higher (reinforced layers) |

|

Cost |

Cheaper |

More expensive |

4. Common Applications

PVC Coated Tarpaulin:

Lightweight truck covers, tents, backpacks.

Short-term outdoor use where flexibility matters.

PVC Laminated Tarpaulin:

Heavy-duty industrial covers (construction, mining).

Marine applications (boat covers, dock seals).

Long-term outdoor use (stadium roofs, permanent shelters).

5. Which One to Choose?

For budget-friendly, flexible needs → PVC Coated.

For extreme weather, heavy-duty use → PVC Laminated.