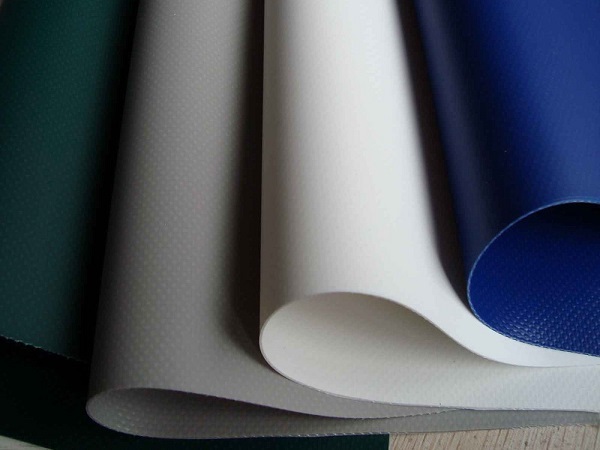

Tear resistance of PVC knife coated tarpaulin

Tear resistance is a critical property of PVC knife-coated tarpaulin, as it determines the material's ability to withstand tearing forces during use. This property is especially important for applications where the tarpaulin is subjected to mechanical stress, such as in transportation, construction, and outdoor use. Below is a detailed explanation of tear resistance, including testing methods, factors affecting tear resistance, and ways to improve it.

1. What is Tear Resistance?

Tear resistance refers to the ability of a material to resist the propagation of a tear once it has been initiated. For PVC knife-coated tarpaulin, this property ensures that small cuts or punctures do not easily spread, maintaining the integrity and durability of the material.

2. Testing Methods for Tear Resistance

Several standardized methods are used to measure the tear resistance of PVC-coated fabrics. The most common include:

a. Elmendorf Tear Test (ASTM D1424)

Principle: Measures the force required to propagate a pre-cut slit in the material using a pendulum device.

Procedure:

A sample is cut with a pre-defined slit.

The sample is clamped in the Elmendorf tear tester.

The pendulum is released, and the force required to tear the sample is recorded.

Result: Tear strength is reported in grams (g) or newtons (N).

b. Tongue Tear Test (ASTM D2261)

Principle: Measures the force required to tear a rectangular sample with a central cut.

Procedure:

A rectangular sample is cut with a central slit.

The sample is clamped in a tensile testing machine.

The machine pulls the sample apart, and the force required to tear it is recorded.

Result: Tear strength is reported in newtons (N) or pounds-force (lbf).

c. Trapezoid Tear Test (ASTM D5587)

Principle: Measures the force required to tear a trapezoidal-shaped sample.

Procedure:

A trapezoidal sample is cut and clamped in a tensile testing machine.

The machine pulls the sample apart, and the force required to tear it is recorded.

Result: Tear strength is reported in newtons (N) or pounds-force (lbf).

3. Factors Affecting Tear Resistance

Several factors influence the tear resistance of PVC knife-coated tarpaulin:

a. Base Fabric (Reinforcement Material)

The type and quality of the reinforcement fabric (e.g., polyester or nylon mesh) significantly impact tear resistance.

Higher denier (thicker) yarns and tighter weaves generally improve tear resistance.

b. PVC Coating Thickness

A thicker PVC coating can enhance tear resistance by providing additional strength and durability.

However, excessive thickness may reduce flexibility.

c. Adhesion Between Coating and Fabric

Strong adhesion between the PVC coating and the base fabric prevents delamination, which can weaken the material and reduce tear resistance.

d. Additives and Fillers

Additives like plasticizers, stabilizers, and fillers (e.g., calcium carbonate) can affect tear resistance.

Overuse of fillers may reduce tear resistance, while optimized formulations can enhance it.

e. Manufacturing Process

Proper knife coating, calendering, and curing processes ensure uniform coating and strong bonding, which improve tear resistance.

4. Improving Tear Resistance

To enhance the tear resistance of PVC knife-coated tarpaulin, consider the following:

a. Use High-Quality Reinforcement Fabric

Choose high-tenacity polyester or nylon fabrics with a tight weave and high denier.

b. Optimize PVC Coating Formulation

Use high-quality PVC resin and plasticizers.

Add tear-resistant additives or modifiers to the coating formulation.

c. Ensure Proper Coating Thickness

Maintain an optimal coating thickness to balance strength and flexibility.

d. Improve Adhesion

Use primers or adhesion promoters to enhance bonding between the PVC coating and the base fabric.

e. Quality Control During Manufacturing

Monitor and control process parameters (e.g., temperature, pressure) to ensure consistent quality.

5. Applications Requiring High Tear Resistance

Transportation: Truck covers, railway covers, and boat covers.

Construction: Temporary shelters, scaffolding covers, and debris containment.

Agriculture: Greenhouse covers, crop covers, and grain storage.

Industrial: Machinery covers and tank covers.

Military: Field shelters and equipment covers.

6. Standards for Tear Resistance

ASTM D751: Standard test methods for coated fabrics, including tear resistance.

ISO 4674: Methods for determining tear resistance of coated fabrics.

EN ISO 13937: Tear resistance testing for textiles and coated materials.

Conclusion

Tear resistance is a vital property of PVC knife-coated tarpaulin, ensuring its durability and performance in demanding applications. By understanding the factors that influence tear resistance and implementing appropriate testing and quality control measures, manufacturers can produce high-quality tarpaulins that meet industry standards and customer expectations.