The Inspection of PVC Knife-coated Tarpaulin

The inspection of PVC knife-coated tarpaulin is a critical process to ensure the product meets quality standards, performance requirements, and customer specifications. Below is a detailed outline of the inspection process, covering both in-process and final product quality control checks:

1. Raw Material Inspection

PVC Resin: Verify the quality, grade, and consistency of the PVC resin.

Plasticizers: Ensure the correct type and quantity are used for flexibility.

Stabilizers: Check for compatibility with the intended application (e.g., UV resistance, thermal stability).

Pigments and Additives: Confirm they meet color and performance specifications.

Reinforcement Material: Inspect the quality of polyester or nylon mesh used for reinforcement.

2. In-Process Inspection

Mixing and Compounding:

Ensure uniform mixing of PVC resin, plasticizers, stabilizers, and additives.

Check for consistent melt temperature and homogeneity during compounding.

Knife Coating Process:

Monitor the coating thickness to ensure uniformity.

Inspect the adhesion between the PVC coating and the reinforcement fabric.

Calendering:

Check the thickness, width, and surface finish of the coated tarpaulin.

Ensure there are no bubbles, cracks, or uneven surfaces.

Cooling:

Verify proper cooling to prevent warping or deformation.

Printing (if applicable):

Inspect print quality, color consistency, and durability.

Edge Sealing and Hemming:

Check for secure and uniform sealing to prevent fraying.

3. Final Product Inspection

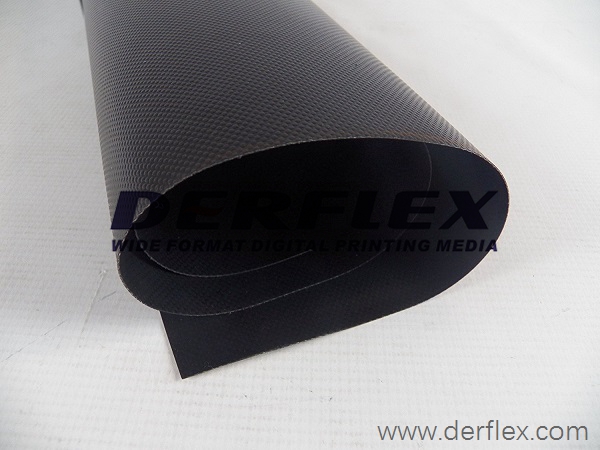

Visual Inspection:

Look for surface defects such as scratches, bubbles, or uneven coating.

Check for consistent color and texture.

Dimensional Accuracy:

Measure length, width, and thickness to ensure they meet specifications.

Verify edge straightness and uniformity.

Weight per Unit Area:

Weigh the tarpaulin to ensure it meets the required weight per square meter.

Tensile Strength Test:

Measure the maximum load the tarpaulin can withstand before breaking.

Tear Resistance Test:

Assess resistance to tearing using standardized methods (e.g., ASTM D751).

Adhesion Test:

Check the bonding strength between the PVC coated fabric.

Flexibility Test:

Ensure the tarpaulin remains flexible at low temperatures (e.g., -20°C to -30°C).

Water Resistance Test:

Verify impermeability by conducting water penetration tests.

UV Resistance Test:

Expose samples to UV light to check for color fading and material degradation.

Flame Retardancy Test (if applicable):

Test for flame resistance according to relevant standards (e.g., EN ISO 11611).

Chemical Resistance Test:

Check resistance to chemicals, oils, and solvents if the tarpaulin is intended for industrial use.

Grommet Inspection:

Verify the correct placement, size, and secure attachment of grommets.

Print Durability (if applicable):

Test for resistance to scratching, peeling, and fading.

4. Packaging Inspection

Ensure the tarpaulin is properly rolled or folded without creases or damage.

Verify that the packaging is secure and protects the product during transit.

Check labeling for accuracy, including product specifications, batch numbers, and safety information.

5. Documentation and Traceability

Maintain detailed records of raw materials, processing parameters, and inspection results.

Ensure traceability by assigning batch numbers to each production run.

Provide certificates of conformity or test reports for customers, if required.

6. Sampling and Testing Frequency

Use statistical sampling methods to test a representative portion of each batch.

Conduct frequent in-process checks to identify and correct issues early in production.

Perform comprehensive final product testing on a per-batch basis.

7. Standards and Compliance

Ensure all tests and inspections comply with relevant industry standards, such as:

ISO 9001: Quality management systems.

ASTM D751: Standard test methods for coated fabrics.

EN ISO 11611: Flame resistance standards.

ISO 1421: Determination of tensile strength and elongation.

8. Key Considerations

Environmental Conditions: Conduct tests under controlled environmental conditions (e.g., temperature, humidity) to ensure accurate results.

Equipment Calibration: Regularly calibrate testing equipment to maintain accuracy.

Continuous Improvement: Use inspection data to identify trends and improve production processes.

Conclusion

The inspection of PVC knife-coated tarpaulin is a comprehensive process that ensures the product meets high-quality standards and performs reliably in its intended applications. By implementing rigorous quality control measures, manufacturers can deliver durable, high-performance tarpaulins that satisfy customer requirements and comply with industry regulations.