I. What is transfer printing?

Transfer printing is a printing technology that uses corresponding pressure to transfer the image and text on the intermediate carrier to the substrate. It can be divided into: water transfer printing, air transfer printing, screen transfer printing, and thermal transfer printing.

II. Advantages of transfer printing.

1. High-quality patterns: Transfer technology can achieve high-quality pattern printing, with clear patterns, high color saturation, strong detail expression, and can present high-quality effects.

2. Wide range of application: Transfer technology is suitable for various materials, including hardware, plastic, leather, glass, ceramics, wood, etc., and is suitable for transfer of various curved surfaces such as full flat surfaces, curved surfaces, and concave and convex surfaces.

3. Innovation: Transfer technology can overcome the limitations of traditional printing and thermal transfer, pad printing, screen printing and other processes, and is suitable for complex shapes and dead corners.

4. Simple operation: Water transfer technology is simple, can be produced manually or semi-automatically, and is easy to operate.

III. Materials transfer printing:

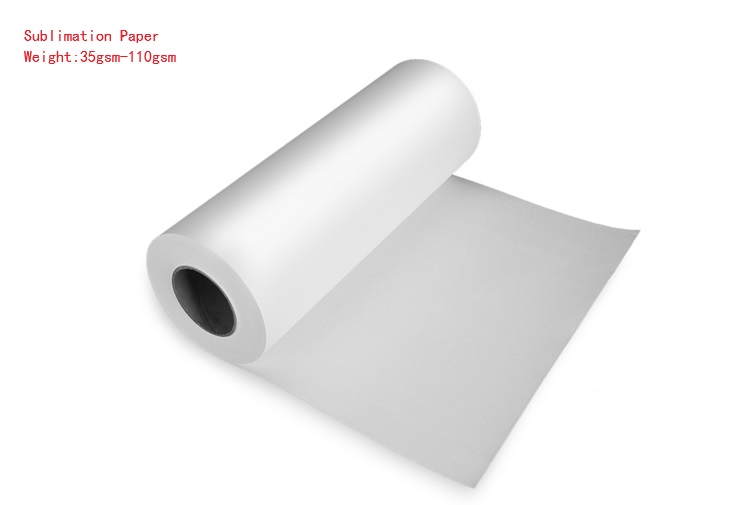

3.1 Dye Sublimation Paper

Sublimation paper applies to sublimation transfer, on which one can print images with mirror reversal through inkjet printing, flat printing, screen printing, and gravure printing. Then transfer the image onto the media by heating and pressuring, which makes the ink on the paper become a gaseous state and combine with the media.

Sublimation Printing Paper is used with sublimation ink. Heat transfer paper is used with sublimation ink, pigment ink, solvent ink or others. Sublimation paper can be transferred onto polyester, mouse pads, banners and hard surfaces, such as mugs, ceramic and aluminum plates. But heat transfer paper is usually transferred onto cotton.

Applications:

Apparel: Lycra materials, cycling, Polyamide, Swim & Surf wear, 100% polyester (stretch), running, ice hockey wear, Sports and functional textiles.

Home Usages: Curtains, Blinds, Cushions, Table Covers, Towel Cleaners, etc.

Advertisement: Flags, Banners, Felts, Gaming tables, Home Textiles.

Sublimation paper has many advantages, including:

- Durable: The dye is embedded into the material, so the image is permanent and won't fade, peel, or crack.

- Vibrant colors: Sublimation printing produces high-quality, photo-realistic images with a wide range of colors.

- Textureless: The design is completely textureless, even when it covers the entire surface.

- UV resistant: The inks are standardly UV resistant.

- Self-weeding: The ink only transfers to the fabric, so there's no need to trim or weed.

- Can print on rigid surfaces: Sublimation is one of the few methods that can print on rigid surfaces, like mugs, plates, and clocks.

- No minimum print run: The unit cost remains the same, whether you print one or a thousand items.

- Efficient: Sublimation printing is efficient and can produce orders quickly, even large quantities.

- Low set-up cost: Sublimation printing doesn't require pretreatment steps, so there's a low set-up cost.

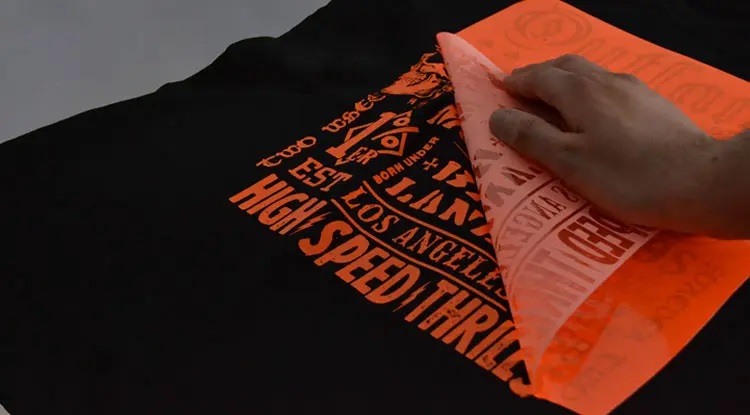

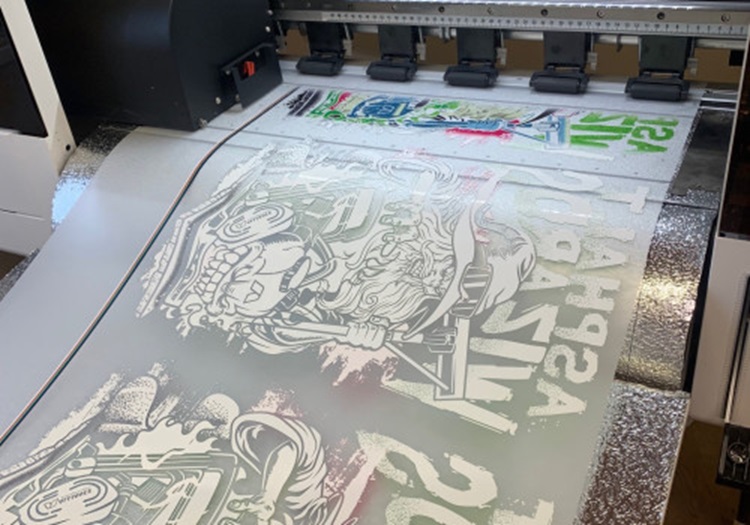

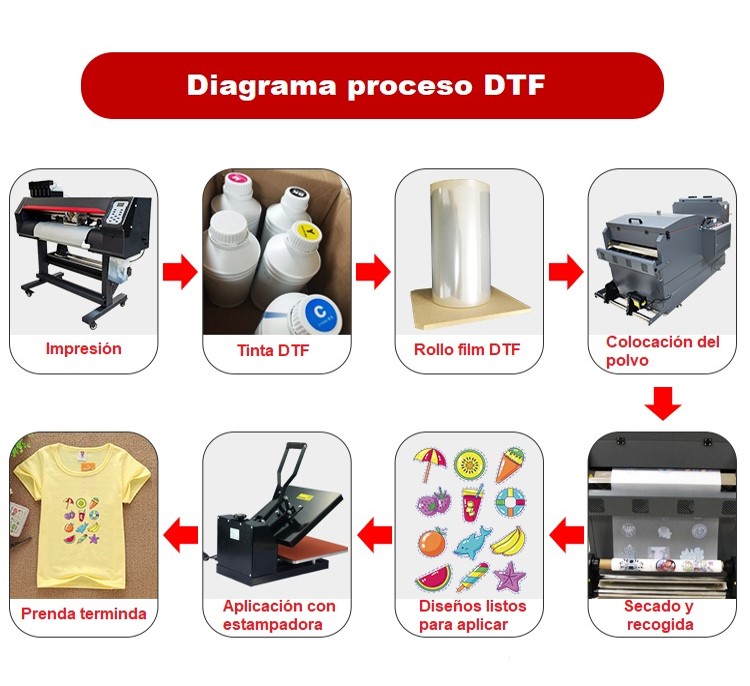

3.2 Direct to Film Printing (DTF)

DTF stands for direct-to-film, a printing technique that involves transferring a design from a film to a fabric using heat and pressure:

- A design is printed on a special film using an inkjet printer modified for DTF printing

- The ink is powdered while still wet

- Adhesive powder is added and cured

DTF printing has several advantages, including:

- Elastic prints: The prints are very elastic and won't crack when the fabric stretches

- Wash and wear resistance: The prints are very resistant to washing and wear

- Low investment: DTF printing is a low investment process

- Can be used on a variety of materials: DTF printing can be used on many materials, including polyester, which is traditionally difficult to decorate

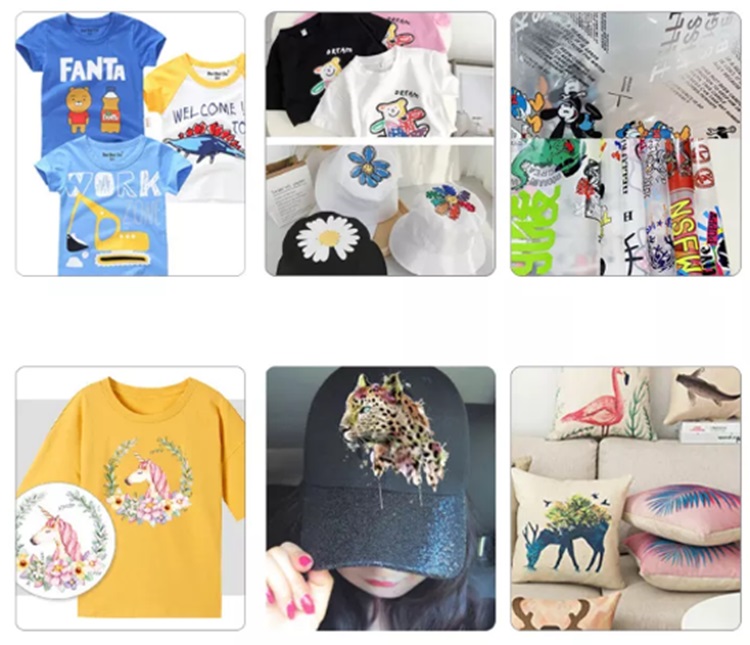

Some materials that DTF printing can be used on include: T-shirts, Cushion covers, Masks, Bags, and Sweatshirts.

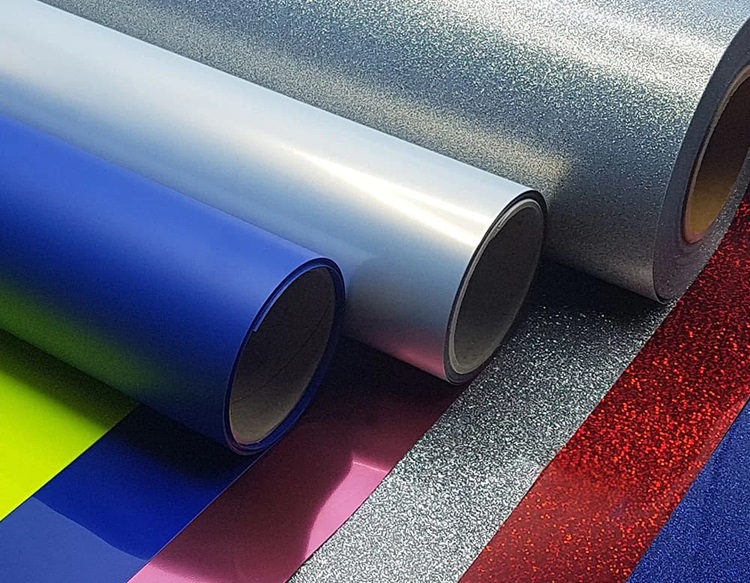

3.3 PU Transfer Film

PU (polyurethane) heat transfer vinyl is a versatile material used for creating designs on fabrics. It comes in rolls or sheets and can be cut into various shapes and designs using a vinyl cutter or plotter. Once cut, the design is transferred onto the fabric using a heat press machine.

PU HTV is ideal for creating detailed designs and numbering on t-shirts, sportswear, and other garments. It can be used on a wide range of fabrics, including cotton, polyester, and blends.

Polyurethane (PU) heat transfer vinyl (HTV) has many advantages, including:

- Durability: PU HTV is known for its durability and can withstand many washes without fading, peeling, or cracking.

- Comfort: PU HTV is soft and lightweight, making it comfortable to wear on fabrics.

- Stretchability: PU HTV can stretch up to 200% without cracking or peeling, making it ideal for flexible applications like athletic wear.

- Heat resistant: PU HTV adheres well to fabric when subjected to heat and pressure.

- Thin and pliable: PU HTV is thinner and more pliable than PVC, making it ideal for intricate designs on garments like T-shirts.

- Child-friendly: PU HTV is suitable for children's wear.

- Easy to use: PU HTV is relatively easy to use and apply to garments with an iron or heat press machine.

- Vibrant colors: PU HTV is known for its vibrant and long-lasting colors.

PU HTV can be used on cotton, polyester, and poly/cotton blends.

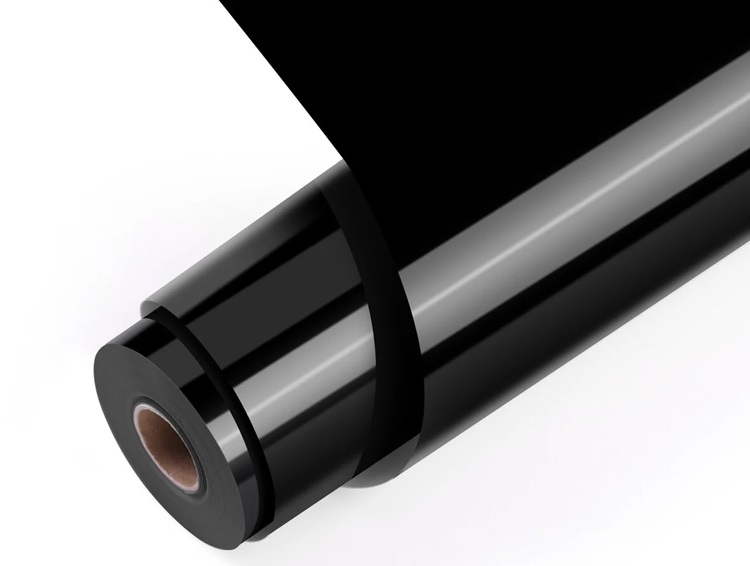

3.4 PVC heat transfer vinyl

PVC heat transfer film is made of PVC material, which is actually a very cost-effective vinyl. It has good hand feeling, certain tensile properties and is washable. And easy to operate, fast, convenient, no plate making.

Advantages of PVC HTV:

Key advantages of PVC heat transfer vinyl:

- High Durability:

PVC is known for its strong and resilient properties, making it ideal for items that need to withstand wear and tear, particularly in outdoor environments.

- Weather Resistant:

PVC can resist extreme temperatures and moisture, making it suitable for outdoor apparel and signage.

- Cost-Effective:

Compared to other vinyl options, PVC is often more affordable, making it a budget-friendly choice for large-scale customization projects.

- Wide Application Range:

PVC heat transfer vinyl can be used on a variety of materials like heavy-duty fabrics, workwear, safety gear, and promotional banners.

- Good Visibility:

The thicker nature of PVC can be advantageous for creating high-visibility designs on safety vests and other items.

Important Considerations:

- Less Flexibility:

PVC is not as flexible as some other vinyl types, so it might not be suitable for garments that require a soft and flexible feel.

- Potential for Bulk:

Due to its thickness, PVC might add noticeable bulk to a garment, depending on the design.

- Not ideal for delicate fabrics:

Applying PVC heat transfer vinyl to delicate fabrics might damage them due to the high heat required during the transfer process.

|

PU Vinyl |

PVC Vinyl |

|

Made with polyurethane |

Made with Polyvinyl Chloride |

|

It is thinner, around 0.08mm |

It is comparatively thicker, around 0.13 to 0.14mm |

|

Soft and flexible stature |

Slightly hard, sturdy, and robust |

|

High elasticity |

Low elasticity |

|

More breathable |

Less breathable |

|

More expensive |

Less expensive |

|

Less variety in colors |

More variety in colors and textures |

|

Best for intricate designs |

Best for large designs and bold lettering |

|

It has three layers - a protective top layer, PU vinyl, and backing |

It has two layers - PVC vinyl and backing |

|

Slightly less sticky |

More sticky with high tack |

IV. About DERFLEX

DERFLEX is professional manufacturer in China focusing on industrial fabrics and digital printing media. We have full solution on transfer printing, for more information, pls contact us freely!

Steven Lee

+8615601786499

steven@derflex.com